Wholesale Price Copper Nickel Alloy CuNi8 CuNi 10 Round Rod Bar

- Product Details

CuNi 10, too known as Copper Nickel 10, is an combination comprising of roughly 10% nickel and the leftover portion being copper. This amalgam is known for its fabulous combination of mechanical and corrosion-resistant properties. Here’s a nitty gritty outline of its characteristics and applications, especially in bar shape

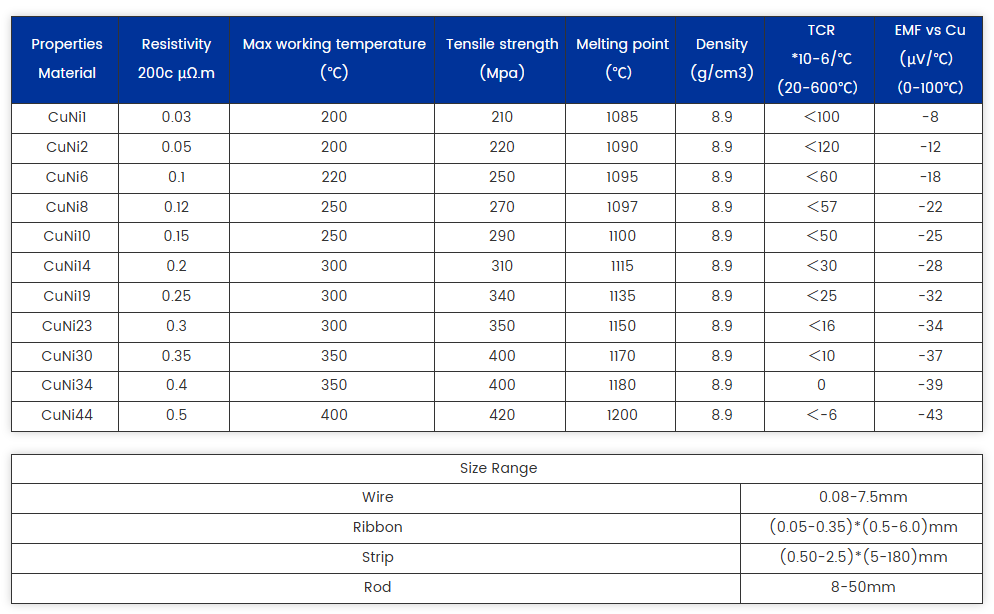

Properties:

Corrosion Resistance:

Exceptional resistance to corrosion, especially in marine environments. It is highly resistant to seawater and other aggressive corrosive media.

Strength and Durability:

Good mechanical strength and durability, making it suitable for structural applications.

Thermal and Electrical Conductivity:

While lower than pure copper, it still maintains good thermal and electrical conductivity.

Ductility and Workability:

High ductility and workability, allowing it to be easily formed, machined, and fabricated.

Non-Magnetic:

Non-magnetic nature, beneficial for applications requiring non-magnetic materials.

Biofouling Resistance:

Resists biofouling, which is crucial in marine applications.

For more details, pls directly contact us.

Applications:

Given its properties, CuNi8 is used in a variety of applications, particularly where corrosion resistance and strength are essential:

Marine Applications:

Commonly used in marine hardware, such as boat hulls, propellers, and seawater piping systems. Its excellent resistance to seawater corrosion makes it ideal for these environments.

Heat Exchangers and Condensers:

Utilized in heat exchangers and condensers, particularly in power plants and desalination plants, due to its thermal conductivity and resistance to corrosion.

Automotive and Aerospace:

Used in automotive and aerospace components that require strength and resistance to harsh environments.

Oil and Gas Industry:

Suitable for use in offshore oil and gas platforms, pipelines, and related equipment.

Electrical Components:

Employed in electrical and electronic components where a combination of conductivity and corrosion resistance is needed.

Desalination Plants:

Extensively used in desalination plants for tubing and piping systems due to its resistance to saline environments.

Industrial Equipment:

Used in various industrial applications, including valves, pumps, and fittings that are exposed to corrosive media.

Specific Form - Rod:

Advantages of Using Rod Form:

Structural Applications: The rod form is particularly useful in structural applications where strength and rigidity are required.

Machining and Fabrication: Rods can be easily machined and fabricated into various components, making them versatile for different applications.

Precision Manufacturing: Suitable for precision manufacturing processes to create custom parts and components.

Overall, CuNi 8 rods are highly valued for their excellent combination of corrosion resistance, strength, and thermal/electrical conductivity, making them suitable for a wide range of demanding applications, especially in marine, industrial, and energy sectors.

About Us:

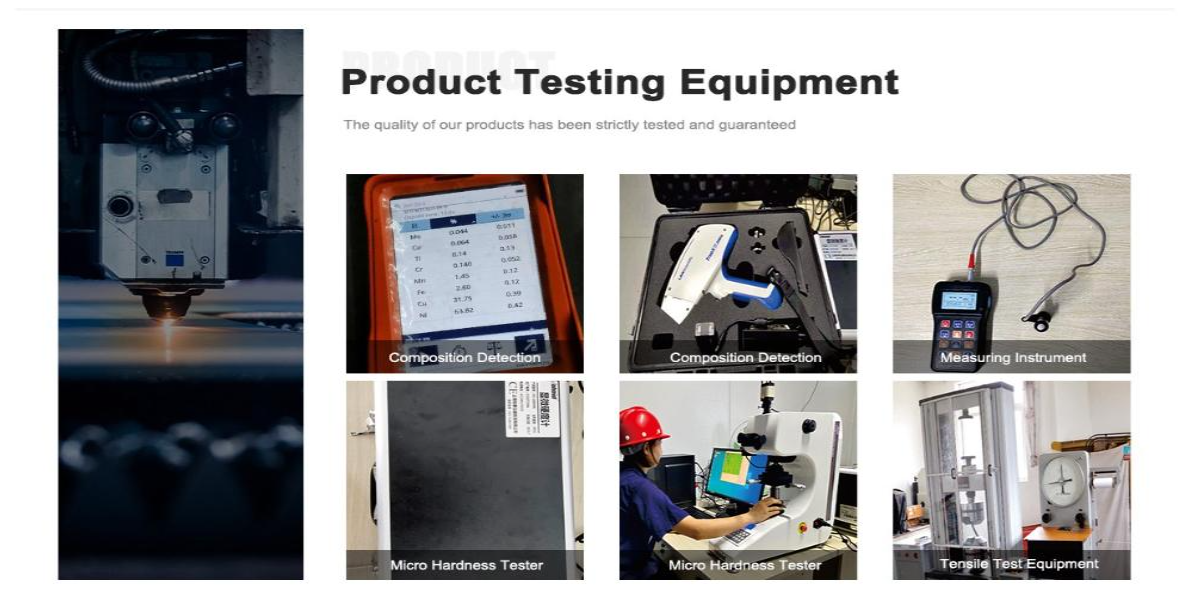

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

1. What is the chemical composition of CuNi8 and CuNi10?

CuNi8 contains ~8% nickel and ~92% copper, while CuNi10 has ~10% nickel. Both may include trace amounts of iron and manganese for added strength and corrosion resistance.

2. Are these alloys suitable for marine or offshore applications?

Yes, both CuNi8 and CuNi10 offer good resistance to seawater corrosion and are commonly used in marine hardware, heat exchangers, and condenser systems.

3. What’s the difference between round rod and round bar?

Technically, rods are often smaller in diameter and used for precision machining, while bars can be larger and used structurally. We supply both based on your size needs.

4. Do you offer wholesale pricing for large orders?

Absolutely. We specialize in bulk supply and offer competitive wholesale pricing with flexible payment and logistics options for large-volume customers.

5. What sizes do you offer for CuNi8 and CuNi10 rods/bars?

Standard diameters range from 6 mm to 100 mm, with lengths up to 6 meters. Custom sizing is available upon request.

6. Can you provide certificates and third-party inspection?

Yes, all shipments include Mill Test Certificates (MTC). SGS, BV, or other third-party inspections can be arranged before dispatch.

7. Are these materials weldable and machinable?

Yes. Both CuNi8 and CuNi10 offer good machinability and are suitable for welding using standard techniques such as TIG and MIG.

8. What is the typical delivery time for wholesale orders?

Standard delivery time is 15–20 working days, depending on quantity and specifications. For urgent needs, we offer prioritized production scheduling.

-

Good Price Nickel Alloy CuNi8 CuNi10 Round & Square Bar For Sale

Enquire Now -

CuNi2 Bar CuNi Alloy Various CuNi Models CuNi2 CuNi6 Bar/ CuNi44 Rod

Enquire Now -

High Quality Customized CuNi Super Alloy Factory Direct Supply Super Bar CuNi8

Enquire Now -

High Quality Constantan CuNi10 Bar For Heating Cables

Enquire Now