Customized Low Resistance Nickel Wire Thermal Circuit Breaker CuNi Alloy Wire

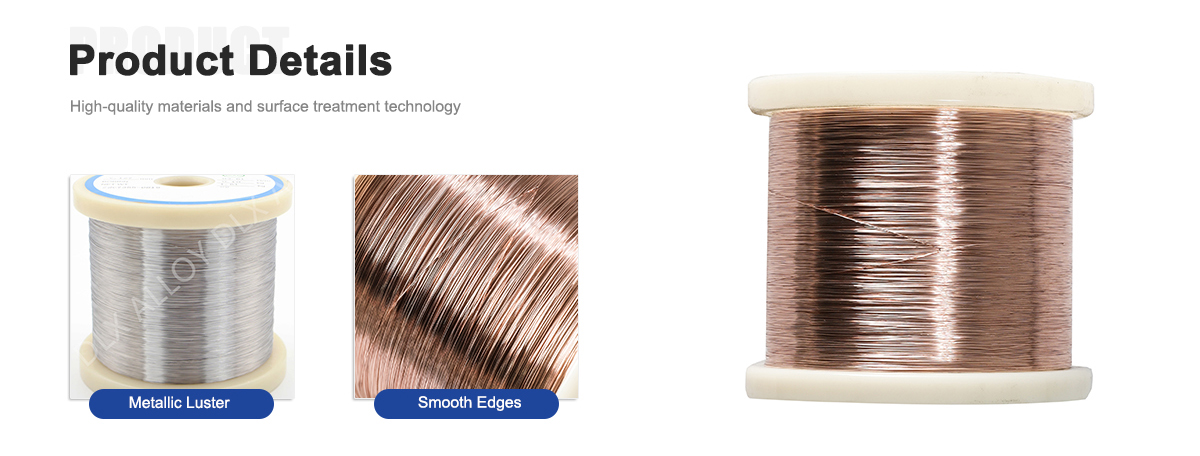

- Product Details

Our customized low resistance CuNi alloy wire is a total rockstar for thermal circuit breakers, and we’re stoked to show why it’s such a killer choice. This copper-nickel alloy is all about precision, durability, and efficiency, built to meet the exact needs of manufacturers crafting reliable circuit protection systems.

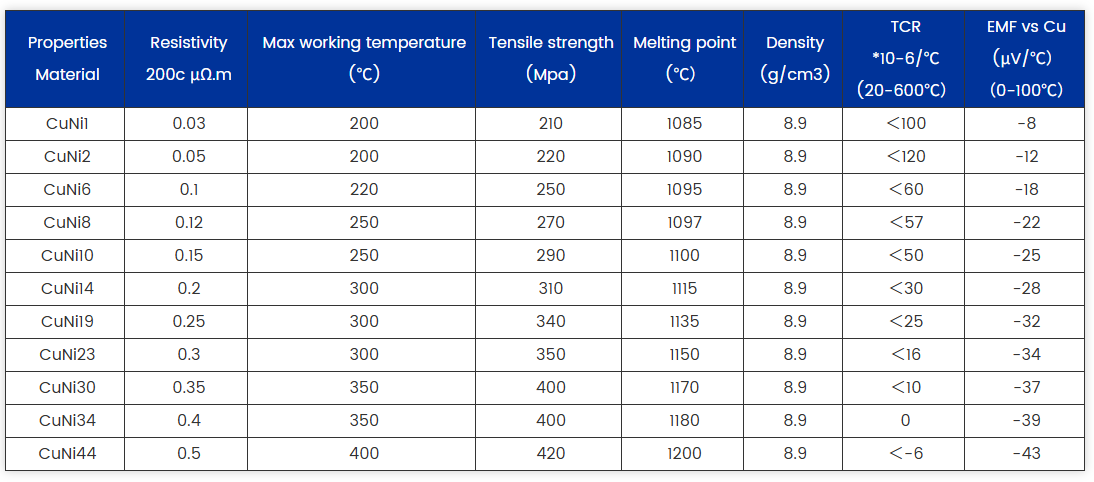

CuNi alloys, with nickel content from 1% to 44% (think CuNi1 to CuNi44), are designed to handle temperatures up to 400°C, making them perfect for the thermal demands of circuit breakers. Their corrosion resistance is next-level, standing up to humid, marine, or industrial environments with a protective oxide layer that keeps rust at bay. The low electrical resistivity, ranging from 0.10 to 0.49 µΩ·m, ensures efficient current flow, keeping energy loss low and breakers quick to respond.

With thermal conductivity between 30-50 W/mK, this wire transfers heat fast and evenly, which is critical for breakers that rely on accurate thermal triggers. Its tensile strength (~300-400 MPa) keeps it tough for long-term use, and the high formability means we can customize it into wires, coils, or specific shapes to match any breaker design. Need a particular diameter or resistance? We’ve got you covered with OEM-level customization.

The industry in 2025 is leaning hard into smart, sustainable solutions, and our CuNi wire is right on the pulse. There’s a big demand for corrosion-resistant, reliable materials in automotive, electronics, and renewable energy sectors, especially for circuit breakers in EVs or solar setups. Being 100% recyclable, it’s a great fit for eco-conscious manufacturing. As compact, high-efficiency breakers keep trending, CuNi’s low resistance and tailor-made options make it a top pick for innovative designs.

Sure, Nichrome Cr20Ni80 can take on higher temperatures, but our CuNi wire’s affordability and corrosion resistance make it ideal for moderate-heat breaker applications. CuNi44 Constantan is close but often pricier with higher resistivity, which can slow things down. Just keep CuNi away from extreme high-heat setups, though it handles most environments like a champ.

From automotive circuit protection to industrial controls, our customized low resistance CuNi alloy wire delivers the precision, reliability, and efficiency that keep manufacturers ahead in the game.

Properties:

Corrosion Resistance:

Good resistance to corrosion, particularly in marine and industrial environments.

Electrical Conductivity:

Maintains good electrical conductivity, though slightly less than pure copper due to the nickel content.

Thermal Conductivity:

High thermal conductivity, making it effective for heat dissipation.

Ductility:

Highly ductile, allowing it to be easily formed into flat wires and other shapes.

Mechanical Strength:

Moderate mechanical strength, which can be enhanced through work hardening.

Non-Magnetic:

Non-magnetic nature, which is beneficial for certain electronic and precision applications.

Applications:

Electrical Connectors and Components:

Used in electrical connectors and components where reliable conductivity and corrosion resistance are required.

Heating Elements:

Suitable for use in heating elements due to its ability to conduct heat effectively.

Marine Applications:

Used in marine hardware and components because of its excellent resistance to seawater corrosion.

Industrial Equipment:

Employed in various industrial applications, such as in the production of pumps and valves exposed to corrosive environments.

Aerospace and Automotive:

Utilized in aerospace and automotive industries for components that require a combination of strength, conductivity, and resistance to harsh environments.

Instrumentation:

Used in precision instrumentation and measurement devices where stable conductivity and corrosion resistance are crucial.

Jewelry and Decorative Items:

Occasionally used in the jewelry industry for its aesthetic appearance and workability.

Specific Form - Flat Wire:

Advantages of Flat Wire:

Space Efficiency: Flat wire can be used in applications where space is limited, as it can be packed more densely than round wire.

Ease of Handling: Easier to handle and install in certain applications due to its flat shape.

Improved Contact: Provides better surface contact in electrical applications, enhancing conductivity.

Flexibility: Offers greater flexibility in design and can be used in a variety of custom shapes and sizes.

About Us:

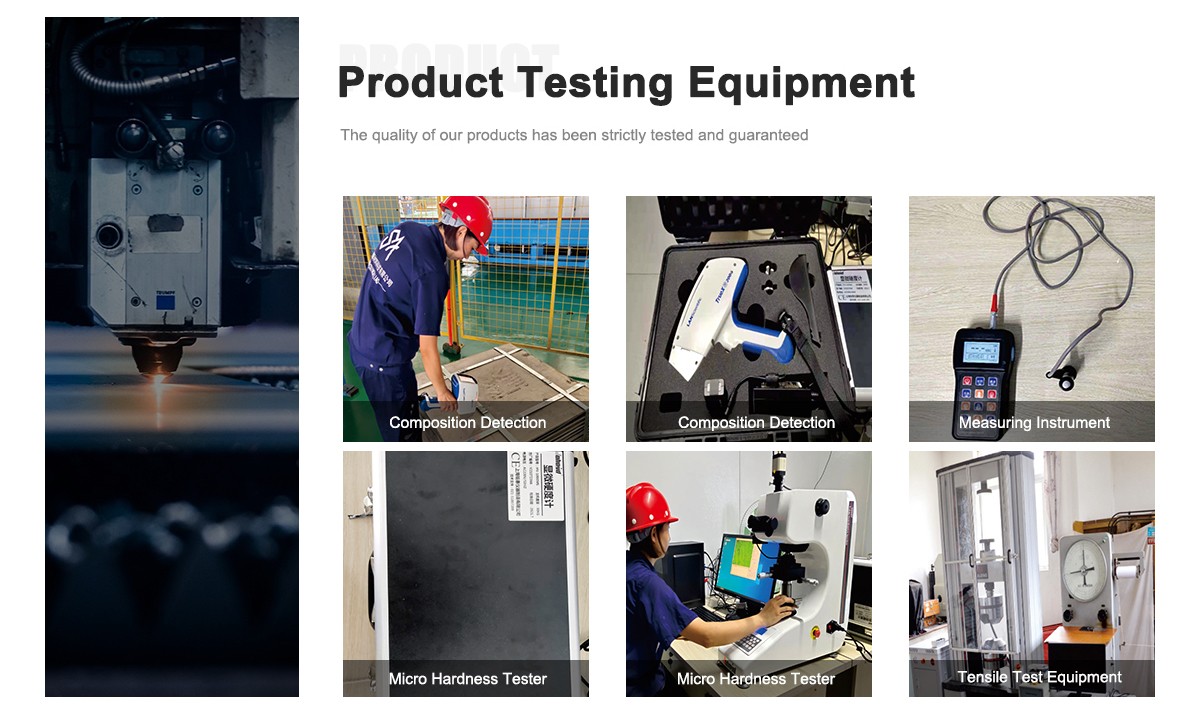

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.

-

Nickel Plated Motor Winding Copper Wire CuNi Alloy 0.012mm-1.0mm Copper Magnet Cable Wire

Enquire Now -

DLX Low Resistance CuNi15 Nickel Copper Alloy Wire

Enquire Now -

Low Resistance Anti-Oxidation 0.03Mm~8Mm CuNi Wire New Constantan Wire Copper Nickel Alloy

Enquire Now -

New Constantan Copper Nickel Alloy Resistance Wire For Sale

Enquire Now