Hardness 120-180 HV with 30-45% Elongation Non magnetic CuNi Wire in Hard or Soft Conditions

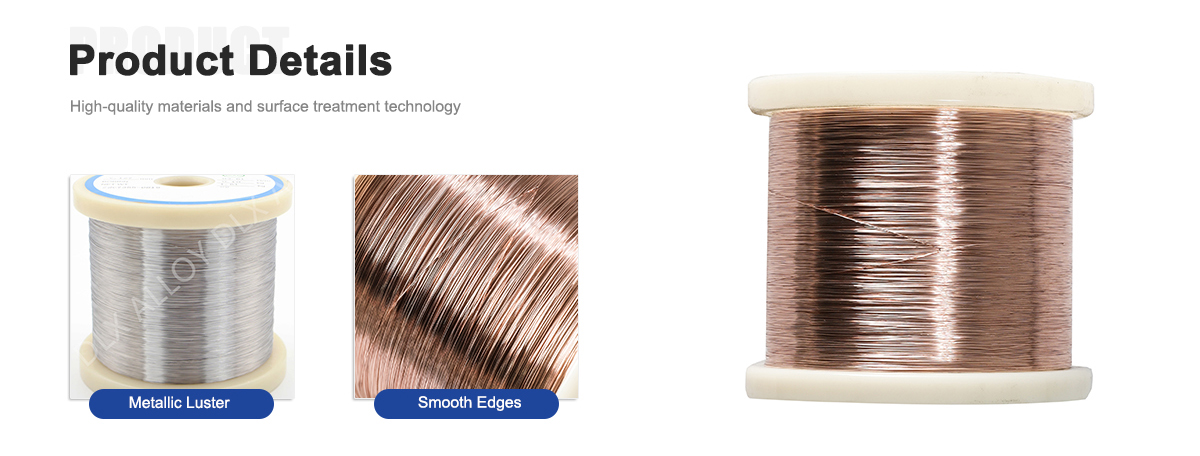

- Product Details

The surface of our CuNi alloy product is bright, making it an aesthetically pleasing option for various applications. Its emf Vs Cu is -28 UV/C, which makes it a good choice for temperature measurement applications. Additionally, it is non-magnetic, which is an important feature in applications where magnetic properties can interfere with performance.

Whether you need a copper tungsten alloy or other copper metal products, our CuNi alloy product is an excellent choice. It is highly durable and can withstand the test of time, making it a reliable option for a variety of applications.

Our CuNi wire, with a hardness of 120-180 HV, 30-45% elongation, and non-magnetic properties, is a total game-changer for industries needing flexibility and reliability. Available in hard or soft conditions, this copper-nickel alloy is built to perform in tough environments, and we’re stoked to show off its potential.

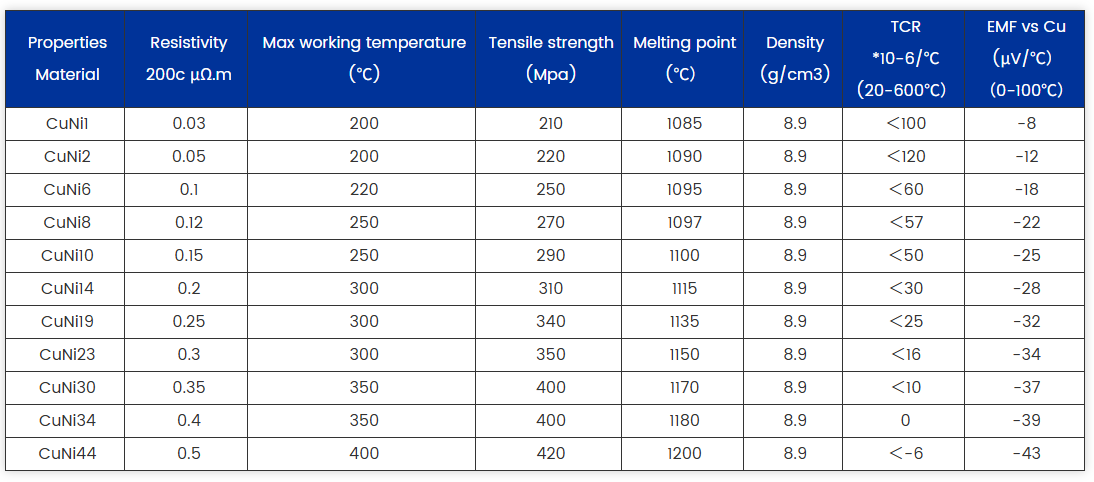

This CuNi wire, with nickel content ranging from 1% to 44% (like CuNi1 to CuNi44), handles temperatures up to 400°C, making it ideal for moderate-heat applications like electrical connectors, heating elements, or precision sensors. Its corrosion resistance is killer, especially in marine or humid environments, where a protective oxide layer keeps rust at bay. The non-magnetic properties are a huge plus, minimizing interference in sensitive electronics like medical devices or aerospace instruments.

The 30-45% elongation means this wire can stretch and bend without breaking, perfect for intricate designs or dynamic systems. With a hardness of 120-180 HV, it strikes a sweet spot—hard condition offers more strength for durability, while soft condition is super pliable for shaping. The electrical resistivity (~0.10-0.49 µΩ·m) ensures stable performance, and its thermal conductivity (~30-50 W/mK) delivers quick, even heat distribution. We can form it into wires, coils, or custom shapes to fit any application.

The industry in 2025 is all about versatility and sustainability, and our CuNi wire is right on trend. There’s a big demand for non-magnetic, corrosion-resistant materials in electronics, marine, and renewable energy sectors, like EV components or offshore wind systems. Being 100% recyclable, it’s a perfect fit for eco-friendly manufacturing. As precision and compact designs keep trending, this wire’s elongation and non-magnetic properties make it a top pick for innovative applications.

Sure, Nichrome Cr20Ni80 can handle higher temperatures, but our CuNi wire’s flexibility and corrosion resistance make it ideal for moderate-heat, interference-free setups. CuNi44 Constantan is similar but often pricier with less elongation. Just keep CuNi away from extreme high-heat environments, though it thrives in most conditions like a pro.

From marine wiring to precision sensors, our CuNi wire with 120-180 HV hardness and 30-45% elongation delivers the flexibility, reliability, and performance that keep industries running strong.

\

\

Features:

Product Name: CuNi Alloy

Hardness: 120-180 HV

Magnetic Properties: Non-magnetic

Resistivity: 0.12μΩ.m20°C

Density: 8.94 G/cm3

Emf Vs Cu: -28 UV/C

This Copper Alloy Bar, also known as Copper Nickel Alloy or Copper Alloy Rod, features a hardness range of 120-180 HV, non-magnetic properties, resistivity of 0.12μΩ.m20°C, density of 8.94 G/cm3 and an emf vs Cu of -28 UV/C.

Applications:

Some of the most common applications for DLX CuNi Wire include:

Marine Industry: This product is ideal for use in the marine industry due to its excellent resistance to saltwater corrosion. It is commonly used in shipbuilding, offshore oil rigs, and other marine applications.

Power Generation: DLX CuNi Wire is also commonly used in power generation applications. Its high electrical conductivity makes it ideal for use in power plant transformers, generators, and other electrical applications.

Electronics: The material's high thermal conductivity makes it ideal for use in electronics. It is commonly used in circuit breakers, relays, and other electronic components.

Automotive Industry: DLX CuNi Wire is also used in the automotive industry. Its high thermal conductivity makes it ideal for use in spark plugs, while its excellent corrosion resistance makes it suitable for use in exhaust systems and other automotive applications.

Medical Industry: This product is also used in the medical industry due to its excellent biocompatibility. It is commonly used in surgical instruments, orthopedic implants, and other medical devices.

In addition to its many applications, DLX CuNi Wire is also available in a range of conditions, including hard and soft. This makes it suitable for use in a variety of scenarios and ensures that it can meet the needs of a wide range of customers.

With a composition of copper and nickel, DLX CuNi Wire is an excellent alternative to other copper metal products. It is also a great alternative to copper tungsten alloy, as it offers similar properties at a lower cost.

Overall, DLX CuNi Wire is a versatile and reliable product that can be used in a wide range of applications. Whether you are in the marine, power generation, electronics, automotive, or medical industry, this product is an excellent choice.

Customization:

DLX offers product customization services for its CuNi Alloy product, also known as Copper Nickel Alloy. Our CuNi Wire is made in China with Cu/Ni material, ensuring high quality and durability. Our standard product has a hardness of 120-180 HV and a bright surface, with a maximum temperature of 350℃ and elongation of 30-45%.

Additionally, we offer customization options for our CuNi Alloy product. We can adjust the hardness, surface, and maximum temperature to fit your specific needs. We can also provide other copper alloys such as Copper Tungsten Alloy, Copper Alloy Plate, and Aluminium Copper Alloy. Contact us for more information on our product customization services.

Support and Services:

Our CuNi alloy product comes with comprehensive technical support and services to ensure optimal performance and reliability. Our team of experts is available to provide guidance on installation, maintenance, and troubleshooting.

We offer a range of services, including:

Custom alloy design and fabrication

Testing and analysis

Product development and optimization

Training and education for customers and partners

Warranty and repair services

Our goal is to provide superior customer service and support, ensuring that our CuNi alloy product meets your specific needs and exceeds your expectations.

Packing and Shipping:

Product Packaging:

The CuNi Alloy product will be packaged securely in a cardboard box with appropriate cushioning materials to prevent any damage during transit. The product will be sealed in a plastic bag to protect it from moisture and other environmental factors. The product specifications and handling instructions will be included in the package.

Shipping:

The CuNi Alloy product will be shipped via a reputable courier service to ensure timely and safe delivery. The shipping cost will be calculated based on the weight and destination of the package. Customers will be provided with a tracking number to monitor the progress of their delivery. We are committed to delivering the product to our customers in the best possible condition.

About Us:

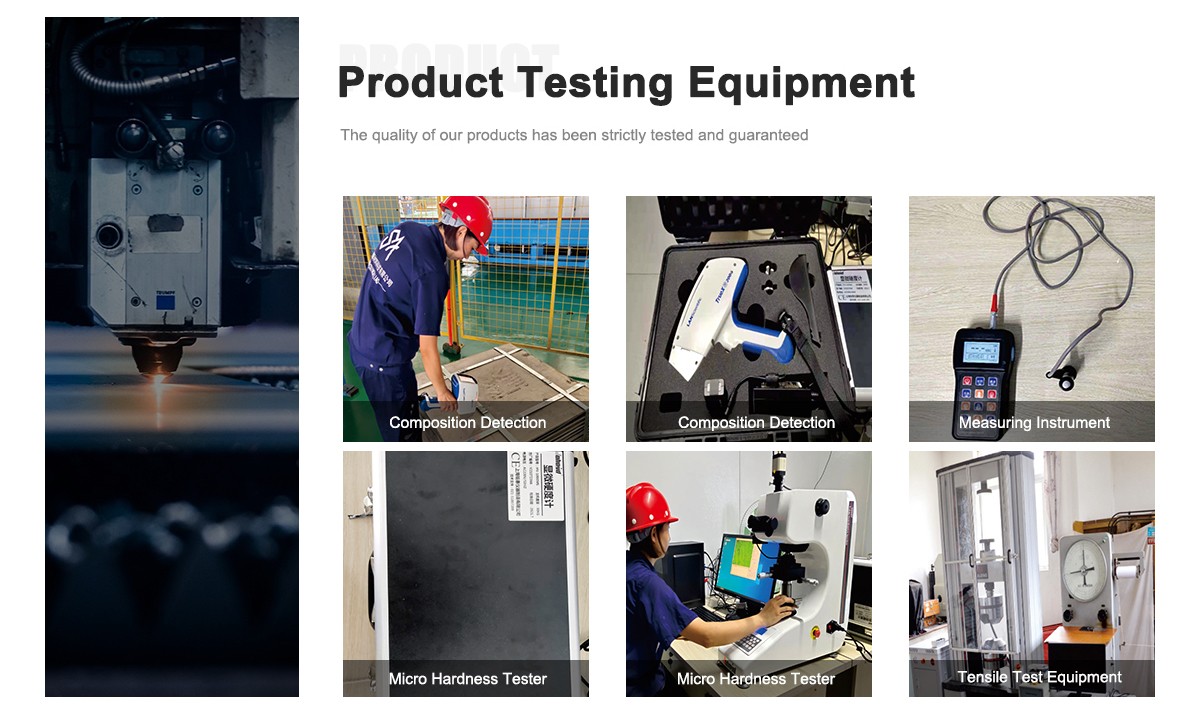

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

Why use CuNi wire with 120-180 HV hardness for industrial applications?

Its balanced hardness and flexibility make it ideal for durable, adaptable components.

What’s the benefit of 30-45% elongation?

It allows the wire to stretch and bend without breaking, perfect for complex designs.

How do non-magnetic properties help?

They minimize interference in sensitive electronics, great for sensors or medical devices.

Can this wire handle corrosive environments?

Yup, it’s super resistant to rust, especially in marine or humid conditions.

What’s the difference between hard and soft conditions?

Hard condition offers more strength; soft condition is more flexible for shaping.

Is this CuNi wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be used in precision electrical systems?

Absolutely, its non-magnetic nature and stable resistivity are perfect for accuracy.

Is this CuNi wire cost-effective?

Yes, it offers great performance at a reasonable price for various applications.

-

Nickel Plated Motor Winding Copper Wire CuNi Alloy 0.012mm-1.0mm Copper Magnet Cable Wire

Enquire Now -

DLX Low Resistance CuNi15 Nickel Copper Alloy Wire

Enquire Now -

Low Resistance Anti-Oxidation 0.03Mm~8Mm CuNi Wire New Constantan Wire Copper Nickel Alloy

Enquire Now -

New Constantan Copper Nickel Alloy Resistance Wire For Sale

Enquire Now