Hot Sale CuNi Alloy Wire Perfect Heating Copper Nickel Wire for Electrical Heating Cable

- Product Details

Our CuNi alloy wire is flying off the shelves, and we’re pumped to share why it’s the perfect choice for electrical heating cables. This copper-nickel alloy is all about delivering efficient, reliable heat while keeping costs down, making it a hot pick for manufacturers and installers alike.

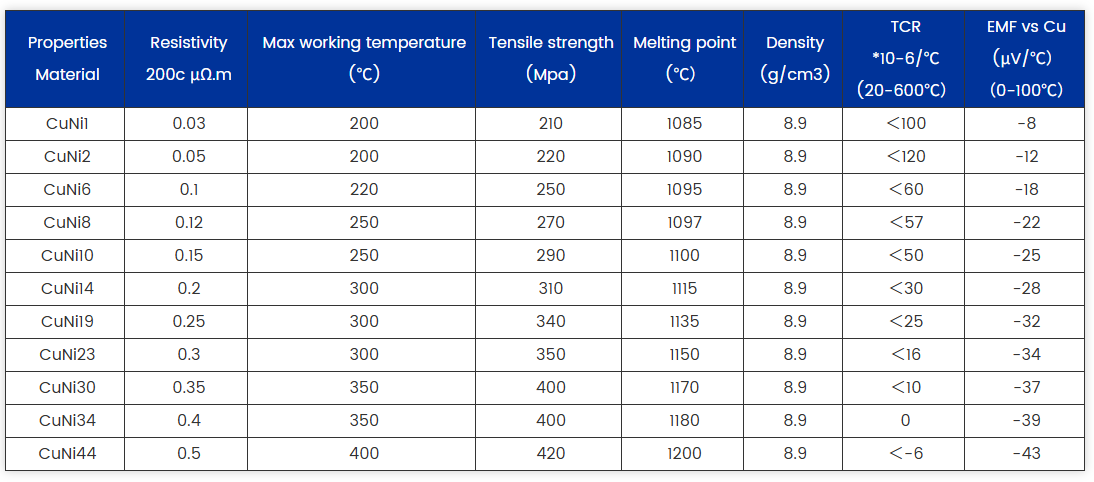

CuNi alloys, with nickel content ranging from 1% to 44% (like CuNi1 to CuNi44), are built to handle temperatures up to 400°C, ideal for heating cables in underfloor systems, industrial heaters, or even marine applications. Its corrosion resistance is top-notch, shrugging off rust in humid or salty environments thanks to a protective oxide layer—perfect for cables exposed to tough conditions. The electrical resistivity, between 0.10 and 0.49 µΩ·m, ensures efficient power delivery, saving energy while keeping things toasty.

With thermal conductivity of 30-50 W/mK, this wire spreads heat fast and evenly, so your heating cables perform consistently without hot spots. Its tensile strength (~300-400 MPa) keeps it durable for long-term use, and the high formability means we can craft it into tight coils or custom shapes to fit any cable design. Whether it’s for thin, flexible cables or thicker, heavy-duty ones, this wire’s got you covered.

The industry in 2025 is all about efficiency and sustainability, and our CuNi wire is right on trend. There’s a massive demand for cost-effective, corrosion-resistant materials in smart homes, automotive, and renewable energy sectors, like electric vehicle heating systems or solar panel cables. Being 100% recyclable, it’s a solid fit for eco-friendly manufacturing. As low-power, high-efficiency heating solutions keep trending, CuNi’s low resistance and high conductivity make it a favorite for cutting-edge designs.

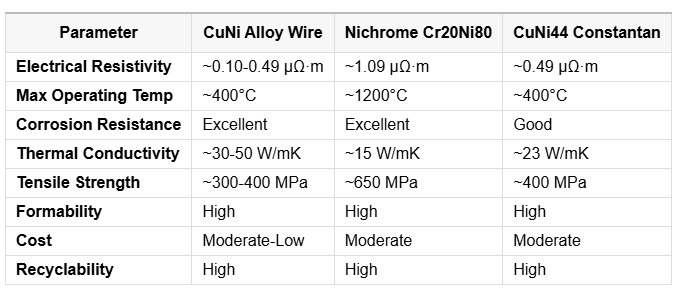

Sure, Nichrome Cr20Ni80 can handle way higher temperatures, but our CuNi wire’s affordability and corrosion resistance make it the go-to for moderate-heat applications. CuNi44 Constantan is similar but pricier with higher resistivity. Just keep CuNi away from extreme high-heat setups, though it thrives in most environments like a pro.

From underfloor heating to industrial cables, our hot sale CuNi alloy wire delivers the efficiency, durability, and value that keep heating systems running strong and customers happy.

Good quality , copper - based low resistance heating alloy wire - CuNi1 NC003 higher cost performance.

Copper-based heating resistance alloy wire indeed offers a plethora of advantageous properties, making it highly suitable for various applications in electrical and heating systems. Its lower electrical resistance ensures efficient energy transfer, while its mechanical strength ensures durability and longevity, particularly in demanding environments.

The excellent welding properties of this alloy wire facilitate easy fabrication and assembly of components, contributing to the manufacturing process's efficiency. Additionally, its anti-corrosion properties are crucial for ensuring the reliability and safety of electrical systems, especially in environments where exposure to moisture or harsh chemicals is a concern.

Tolerance of ohm/m: ±5%

Round wire: range from 0.04mm (0.0016″) to 12mm (0.4724″)

Ribbon: range from 0.05mm (0.002″) to 6mm (0.2362″), Max ratio width : thickness = 10:1

About Us:

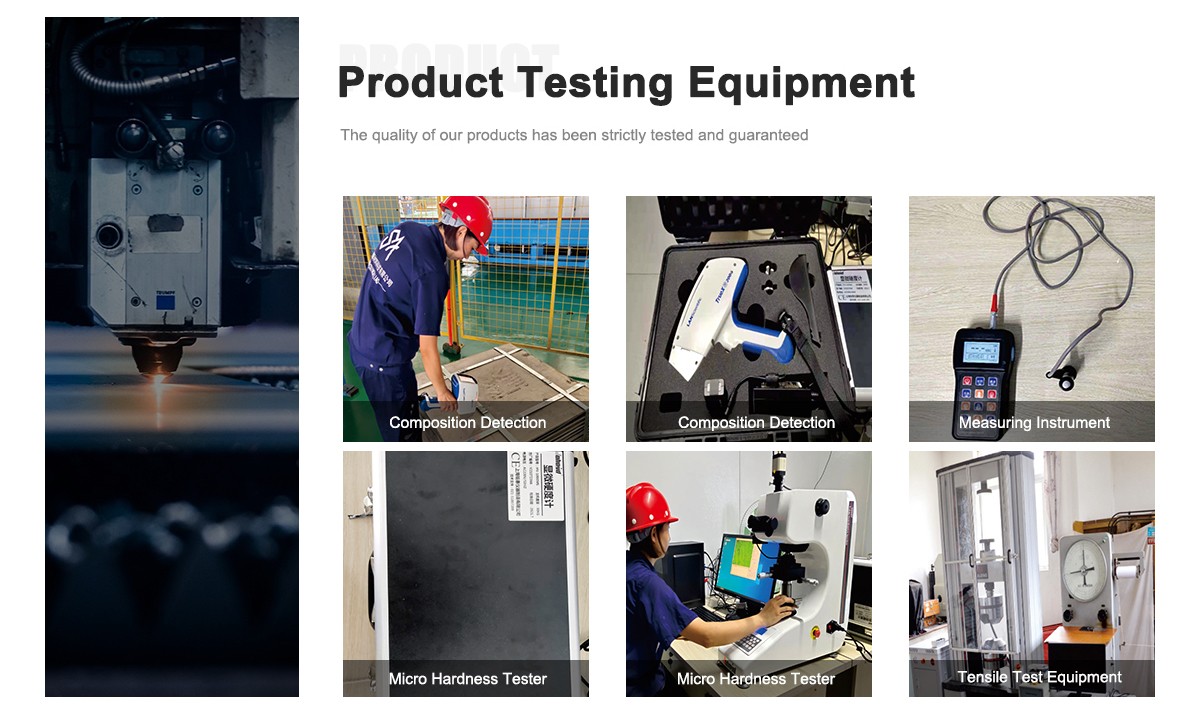

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why use CuNi alloy wire for electrical heating cables?

Its low resistance and corrosion resistance make it ideal for efficient, long-lasting heating systems.

How does CuNi compare to Nichrome for heating cables?

CuNi is more cost-effective with lower resistivity but suited for lower temperatures than Nichrome.

Can this wire handle heating cable temperatures?

Yup, it’s stable up to 400°C, perfect for most electrical heating cable applications.

Is CuNi wire corrosion-resistant in humid environments?

Totally, it’s built to resist rust, especially in damp or marine settings.

What’s the benefit of its high thermal conductivity?

It ensures quick, even heat distribution, great for consistent cable performance.

Is this CuNi wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be used in underfloor heating systems?

Absolutely, its formability and efficiency make it a top choice for floor heating cables.

Is CuNi alloy wire cost-effective for mass production?

Yes, it offers great performance at a budget-friendly price for high-volume manufacturing.

-

Nickel Plated Motor Winding Copper Wire CuNi Alloy 0.012mm-1.0mm Copper Magnet Cable Wire

Enquire Now -

DLX Low Resistance CuNi15 Nickel Copper Alloy Wire

Enquire Now -

Low Resistance Anti-Oxidation 0.03Mm~8Mm CuNi Wire New Constantan Wire Copper Nickel Alloy

Enquire Now -

New Constantan Copper Nickel Alloy Resistance Wire For Sale

Enquire Now