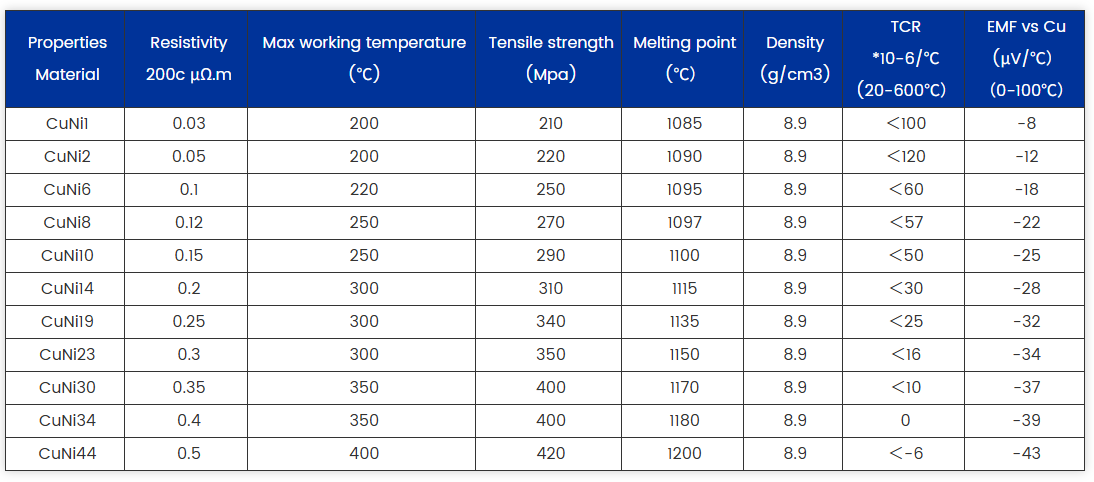

CuNi 23% Alloy Wire with 50 X10-6/C Thermal Expansion and 0.12 micro ohm meter Resistivity

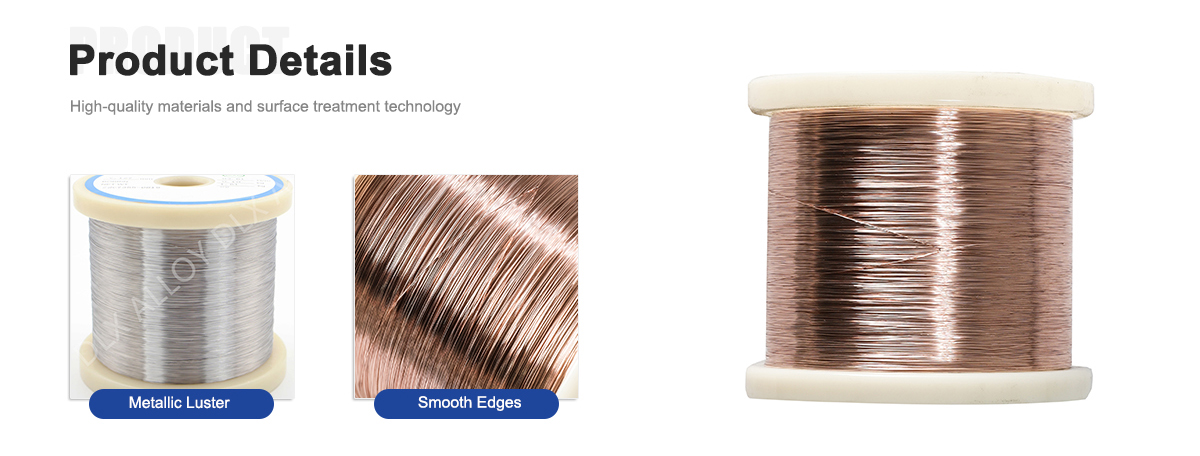

- Product Details

Our CuNi 23% alloy wire, with a thermal expansion of 50 x10^-6/°C and a super low 0.12 µΩ·m resistivity, is a total standout for industries needing precision and reliability. This copper-nickel wire is crafted to deliver awesome performance in tough environments, and we’re stoked to share what it’s all about.

With ~23% nickel and the rest copper, this alloy is built to handle temperatures up to 350°C, making it perfect for moderate-heat setups like electrical connectors, heating cables, or precision sensors. Its corrosion resistance is killer, especially in marine or humid environments, where a protective oxide layer keeps rust at bay. The low resistivity of 0.12 µΩ·m means it conducts electricity super efficiently, saving power in applications like low-power resistors or wiring systems.

The thermal expansion of 50 x10^-6/°C is a big deal—it keeps the wire’s dimensions stable even as temperatures shift, which is crucial for precision components that can’t afford to warp. With a tensile strength of ~350 MPa and thermal conductivity of ~35 W/mK, it’s durable and spreads heat evenly, making it great for systems needing quick thermal response. Plus, its high formability lets us shape it into fine wires or custom designs, perfect for everything from tiny sensors to robust marine applications.

The industry in 2025 is all about efficiency and sustainability, and our CuNi 23% wire is right on trend. There’s a huge demand for corrosion-resistant, cost-effective materials in marine, automotive, and renewable energy sectors, like offshore wind or electric vehicle systems. Being 100% recyclable, it’s a solid fit for eco-friendly manufacturing. As precision electronics and compact devices keep trending, this wire’s low resistivity and stable thermal expansion make it a top choice for reliable, high-volume production.

Sure, Nichrome Cr20Ni80 can handle way higher temperatures, but our CuNi 23% wire’s low resistivity and corrosion resistance make it ideal for moderate-heat, wet environments. CuNi44 Constantan has better heat resistance but higher resistivity and cost. Just keep this CuNi wire away from extreme high-heat setups, though it thrives in most corrosive conditions like a champ.

From marine wiring to precision sensors, our CuNi 23% alloy wire delivers the corrosion resistance, stability, and efficiency that keep industries running smooth and strong.

Product Description:

The CuNi Alloy has a bright surface finish that not only provides an aesthetically pleasing appearance but also enhances its resistance to corrosion. This material is known for its outstanding non-magnetic properties, making it a popular choice for applications where magnetic interference is a concern.

The CuNi Alloy is an excellent choice for use in marine environments due to its resistance to seawater corrosion. It is also commonly used in oil & gas applications, where it can withstand harsh and corrosive environments. In power generation, the CuNi Alloy is used in heat exchangers, condensers, and other equipment that requires high thermal conductivity. In chemical processing, this alloy is used for its exceptional resistance to chemical corrosion.

The CuNi Alloy has an elongation of 30-45%, which means it can be easily formed and shaped into various structures. This property is particularly useful for applications that require complex shapes or custom designs.

Compared to other materials such as copper tungsten alloy, copper bronze alloy, or alloy steel material, the CuNi Alloy offers unique advantages such as its non-magnetic properties, outstanding corrosion resistance, and high thermal conductivity.

Applications:

One of the most common applications of DLX CuNi Alloy is in the production of Copper Alloy Plate. The material's high density of 8.94 G/cm3 and low resistivity of 0.12μΩ.m20°C make it ideal for manufacturing copper alloy plates with excellent electrical conductivity. These plates are used in various electrical applications, such as transformers, motors, and generators.

Another application of DLX CuNi Alloy is in the production of Copper Bronze Alloy. The material's high elongation and excellent corrosion resistance make it a perfect choice for manufacturing copper bronze alloys. These alloys are used in various applications, such as marine and architectural applications, where corrosion resistance is critical.

The Emf Vs Cu of DLX CuNi Alloy is -28 UV/C, making it an excellent choice for use in thermocouples. Thermocouples are temperature sensors that are used in various industries, such as power generation, food processing, and pharmaceuticals. The material's excellent thermal stability makes it an ideal choice for manufacturing thermocouples that can withstand extreme temperatures.

In conclusion, DLX CuNi Alloy is a versatile material that can be used in various product applications. Its excellent mechanical and electrical properties make it an ideal choice for manufacturing Copper Alloy Plate, Copper Bronze Alloy, and thermocouples. Its unique combination of properties makes it an excellent alternative to traditional copper alloys.

Support and Services:

The CuNi alloy product technical support and services are designed to ensure maximum performance and reliability of the product. Our technical support team is available to provide assistance with any product-related questions or issues, including installation, maintenance, and troubleshooting.

We offer a range of services to help you get the most out of your CuNi alloy product, including:

Customized product solutions to meet your specific needs

Technical consulting to optimize product performance

Training and education to ensure proper product use and maintenance

On-site support and repair services

Our team of experts is committed to providing exceptional customer service and support. Contact us today for more information on how we can assist you with your CuNi alloy product needs.

Packing and Shipping:

Product Name: CuNi Alloy

Description: A copper-nickel alloy with high strength and corrosion resistance.

Package Includes: 1 roll of CuNi Alloy

Package Dimensions: Length: 100m, Width: 10cm, Height: 10cm

Package Weight: 5kg

Shipping Method: Standard Shipping

Shipping Time: 5-7 business days

Shipping Cost: $20

About Us:

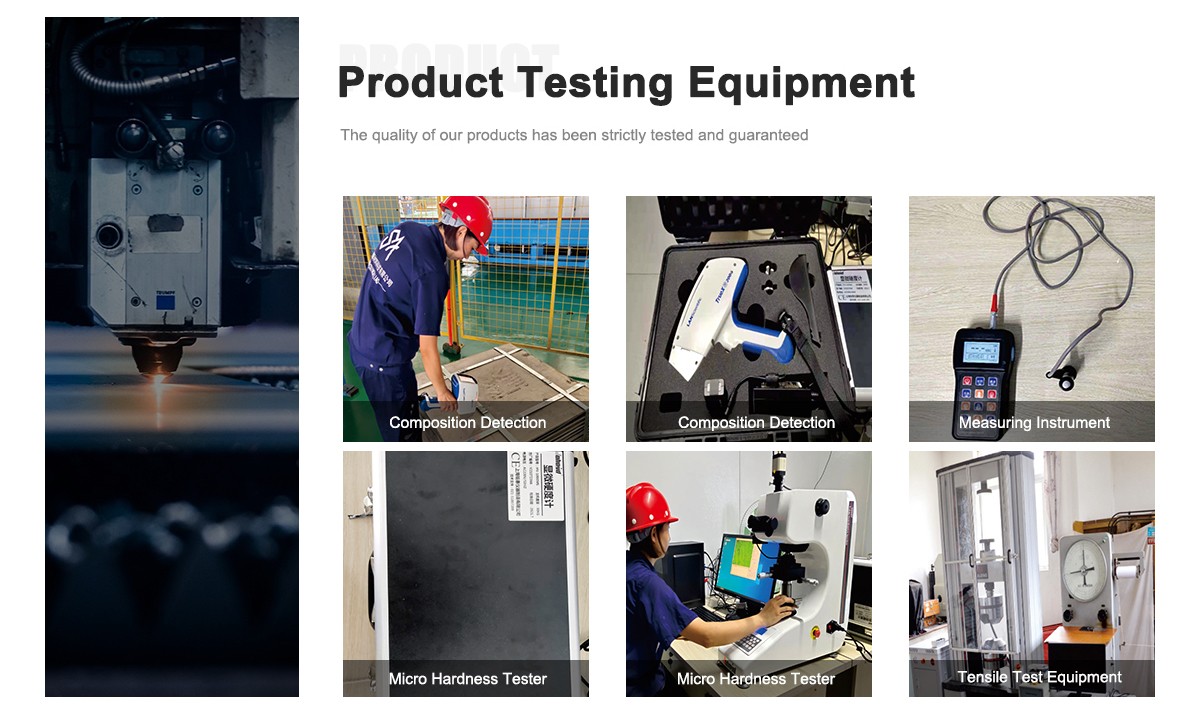

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why use CuNi 23% alloy wire for electrical applications?

Its low resistivity and corrosion resistance make it perfect for efficient, reliable systems.

What does 50 x10^-6/°C thermal expansion mean?

It ensures minimal dimensional change with temperature shifts, ideal for stable designs.

Can this wire handle moderate temperatures?

Yup, it’s stable up to 350°C, great for low-to-moderate heat applications.

Is CuNi 23% wire corrosion-resistant in marine settings?

Totally, it’s built to withstand salty, humid environments like a pro.

What’s the benefit of 0.12 µΩ·m resistivity?

It allows efficient power delivery, perfect for cost-effective electrical setups.

Is this CuNi wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be used in precision sensors?

Absolutely, its stable resistivity and thermal expansion are ideal for accurate devices.

Is CuNi 23% wire cost-effective?

Yes, it balances performance and affordability for long-term applications.

-

Nickel Plated Motor Winding Copper Wire CuNi Alloy 0.012mm-1.0mm Copper Magnet Cable Wire

Enquire Now -

DLX Low Resistance CuNi15 Nickel Copper Alloy Wire

Enquire Now -

Low Resistance Anti-Oxidation 0.03Mm~8Mm CuNi Wire New Constantan Wire Copper Nickel Alloy

Enquire Now -

New Constantan Copper Nickel Alloy Resistance Wire For Sale

Enquire Now