CuNi Alloy The Optimal Choice for Corrosion Resistance and Long-Term Performance

- Product Details

Our CuNi alloy is a total superstar, and we’re pumped to share why it’s the optimal choice for applications needing killer corrosion resistance and long-term performance. This copper-nickel alloy is built to last, delivering reliability and efficiency in some of the toughest environments out there.

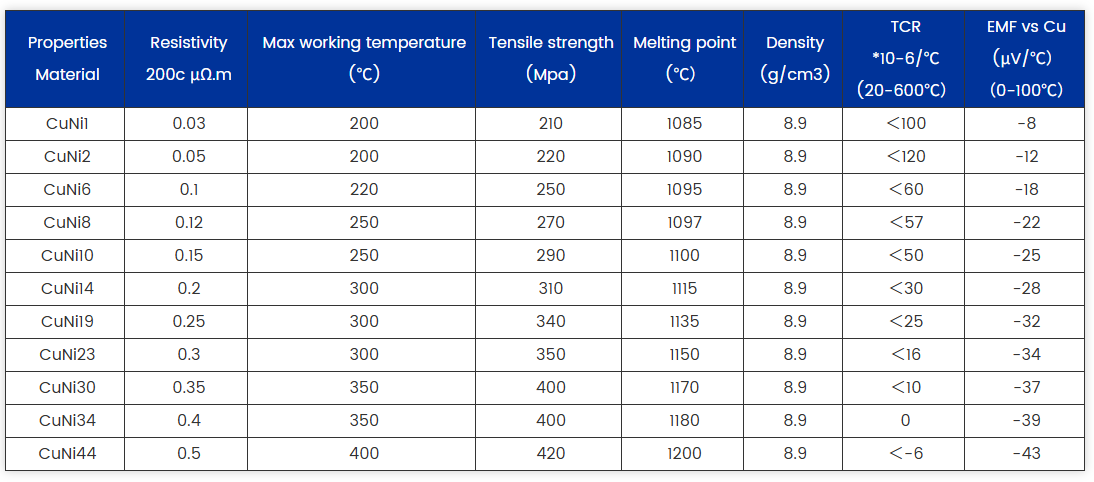

CuNi alloys, with nickel content ranging from 1% (like CuNi1) to 44% (like CuNi44), are champs at fighting corrosion, especially in marine, chemical, or humid settings. A protective oxide layer keeps rust and degradation at bay, making it a go-to for things like shipboard wiring or heat exchangers. They’re stable up to 400°C, perfect for moderate-heat applications, and their electrical resistivity (0.10-0.49 µΩ·m) stays rock-steady, ensuring consistent performance in resistors, sensors, or heating elements.

The thermal conductivity, between 30-50 W/mK, is a big win, allowing quick and even heat distribution, which is awesome for systems needing efficient thermal management. With a tensile strength of ~300-400 MPa, these alloys are tough enough for long-term use without wearing out. Plus, their formability is top-notch—we can shape them into wires, flat strips, or tubes for all kinds of custom designs, from precision electronics to heavy-duty industrial components.

The industry in 2025 is all about sustainability and reliability, and our CuNi alloy is right on trend. There’s a huge demand for corrosion-resistant, long-lasting materials in marine, renewable energy, and automotive sectors. Being 100% recyclable, it’s a perfect fit for eco-friendly manufacturing goals. As industries push for compact, efficient systems like electric vehicle components or offshore wind turbines, CuNi’s versatility and durability make it a top pick.

Sure, Nichrome Cr20Ni80 can handle much higher temperatures, but CuNi’s corrosion resistance in wet environments and lower cost make it ideal for moderate-heat applications. Stainless Steel 304 is durable but less conductive and more prone to corrosion in saltwater. Just keep CuNi away from extreme high-heat setups, though it thrives in most corrosive conditions like a pro.

From marine wiring to precision sensors, our CuNi alloy delivers the corrosion resistance, longevity, and performance that keep industries running strong and reliable for the long haul.

Product Description:

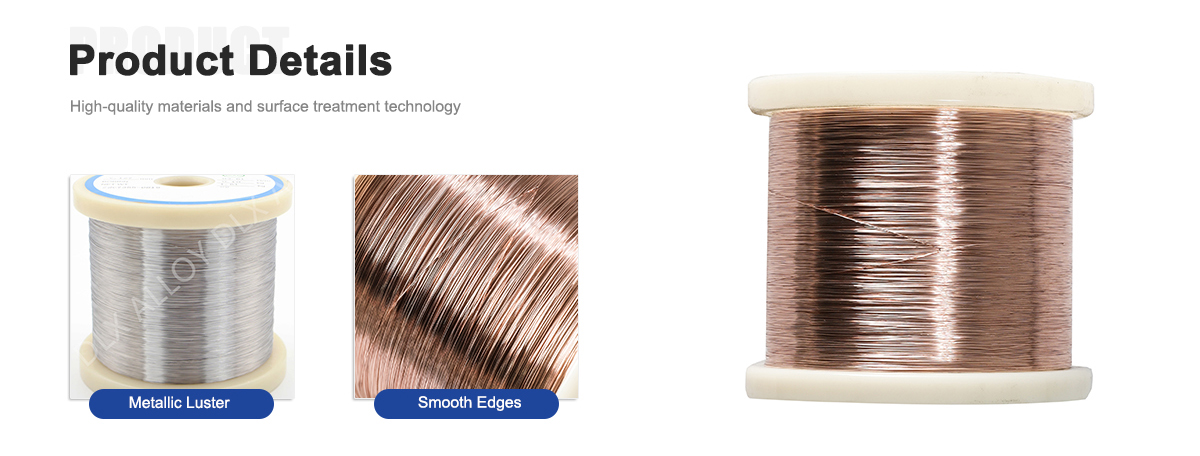

The CuNi Alloy is surface-treated to be bright, making it a perfect material for decorative applications. The surface finish of the material is also ideal for applications where the material needs to be exposed to moisture or other harsh environmental conditions. The bright surface finish of the CuNi Alloy is achieved through various finishing processes, including electro-polishing or mechanical polishing.

The CuNi Alloy is available in different diameters, ranging from 0.1 to 10mm. The diameter of the material is an essential factor to consider when choosing the right type of copper-nickel alloy for your application. The CuNi Alloy's diameter determines its strength and durability, making it an essential factor in the material's overall performance.

The CuNi Alloy is available in both hard and soft conditions. The condition of the material determines its tensile strength, which is essential in various applications. The hard condition of the CuNi Alloy is ideal for applications that require high tensile strength, while the soft condition is perfect for applications where the material needs to be formed or shaped easily.

The CuNi Alloy is non-magnetic, making it an ideal material for applications where magnetic properties are undesirable. The non-magnetic properties of the CuNi Alloy make it an excellent material for use in medical equipment, electronic devices, and other applications where the presence of a magnetic field can cause problems.

The density of the CuNi Alloy is 8.94 G/cm3, making it a relatively lightweight material compared to other types of copper alloys. The material's low density makes it an excellent choice for applications where weight is a critical factor, such as in aerospace or automotive industries.

In conclusion, the CuNi Alloy is a highly versatile material that is widely used in various applications. Its excellent corrosion resistance, high strength, and non-magnetic properties make it an ideal material for numerous applications. Whether you need alloy parts, alloy steel material, or copper alloy rod, the CuNi Alloy is an excellent choice for your next project.

Applications:

The CuNi Alloy from DLX is widely used in the manufacturing of electrical components. Due to its excellent electrical conductivity, this alloy is used to make connectors, relays, and switches. It is also used in the production of heating elements and thermocouples. With an EMF vs Cu of -28 UV/C, this alloy is highly suitable for use in thermocouples, as it produces a stable voltage output.

The DLX CuNi Alloy is also an excellent choice for use in the marine and shipbuilding industries. Due to its outstanding resistance to corrosion, this alloy is used to manufacture various parts of ships and boats. It is also used to make components for desalination plants and other seawater processing equipment.

The CuNi Alloy from DLX is also used in the aerospace industry. With a maximum temperature of 350℃, this alloy is ideal for use in high-temperature applications. It is used to make various parts of aircraft engines and other aerospace components.

In the automotive industry, the DLX CuNi Alloy is used to manufacture various parts. Due to its excellent heat resistance and thermal conductivity, this alloy is used to make parts such as exhaust systems and engine components. It is also used in the production of brake systems and other safety-critical parts.

DLX CuNi Alloy is also used in the production of aluminum copper alloy and copper tungsten alloy parts. Due to its excellent thermal and electrical conductivity, this alloy is used as a bonding material in the production of these alloys. The resulting parts have excellent mechanical and electrical properties.

In conclusion, the DLX CuNi Alloy is a highly versatile product that finds application in a wide range of industries. It is widely used in the production of electrical components, marine and shipbuilding industries, aerospace industry, automotive industry, and the production of aluminum copper alloy and copper tungsten alloy parts. With its outstanding mechanical, thermal, and electrical properties, this alloy is an excellent choice for various scenarios.

Support and Services:

Our CuNi Alloy product comes with comprehensive technical support and services to ensure that our customers receive the best possible performance and value from their purchase. Our team of experts is available to provide technical assistance and advice on any aspect of the product, including its installation, operation, and maintenance.

In addition, we offer a range of services to support our customers throughout the entire lifecycle of the product. These include:

Training and education programs to help our customers maximize the benefits of the product

Customized solutions to meet specific customer requirements

Repair and maintenance services to ensure the continued reliability and performance of the product

Technical documentation and information to help our customers make informed decisions about their purchase

At every step of the way, our goal is to provide our customers with the highest level of satisfaction and support. We are committed to delivering products and services that meet or exceed their expectations, and to building long-lasting relationships based on trust and mutual respect.

Packing and Shipping:

Product Packaging:

The CuNi Alloy product will be securely packed in a wooden box to prevent any damage during transportation.

The wooden box will be sealed properly to ensure that the product stays safe and protected.

The product will be labeled clearly with all the necessary information, including product name, quantity, and any handling instructions.

Shipping:

The CuNi Alloy product will be shipped via a reliable and reputable shipping company.

The product will be shipped within the agreed-upon timeframe.

The shipment will be insured to protect against any loss or damage during transit.

The customer will be provided with a tracking number to monitor the status of their shipment.

About Us:

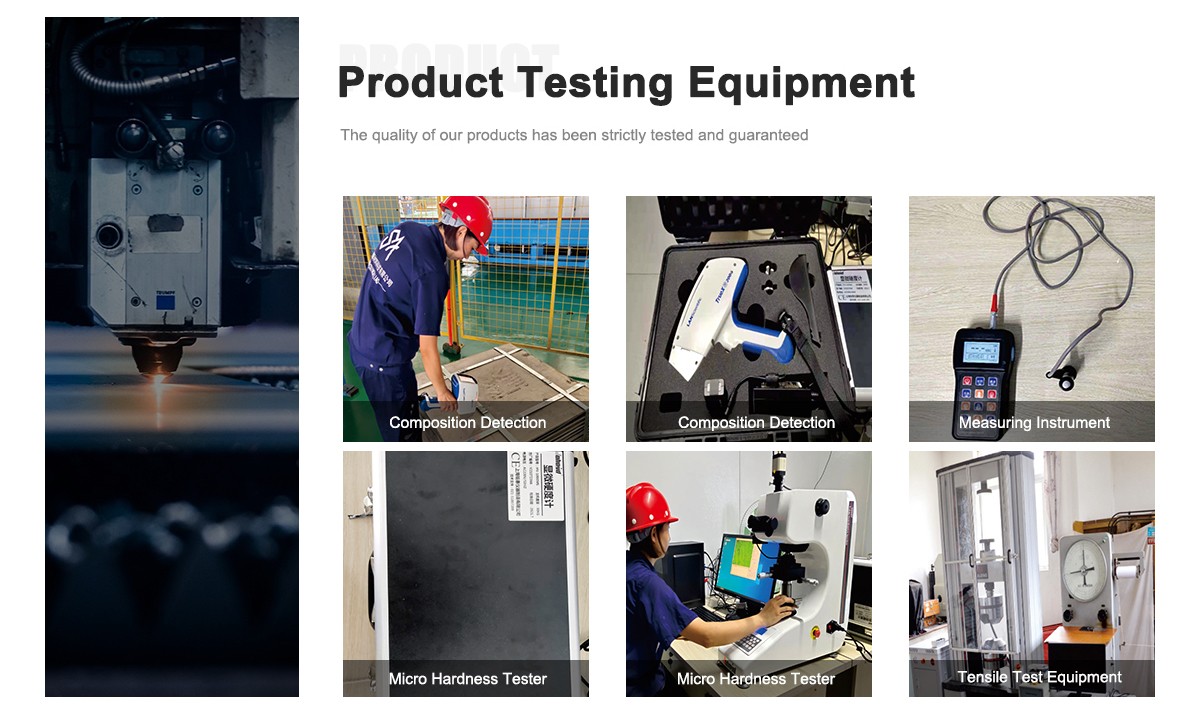

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why use CuNi alloy for corrosion-resistant applications?

Its exceptional corrosion resistance makes it ideal for harsh environments like marine or chemical settings.

How does CuNi alloy ensure long-term performance?

Its durability and stable properties keep it reliable over years of use.

Can CuNi alloy handle high temperatures?

Yup, it’s stable up to 400°C, perfect for moderate-heat applications.

What’s the difference between CuNi grades like CuNi6 and CuNi30?

Higher nickel content (e.g., CuNi30) increases resistivity and heat resistance but raises cost.

Is CuNi alloy suitable for marine environments?

Totally, it’s a go-to for saltwater applications due to its protective oxide layer.

Is this alloy recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can CuNi alloy be used in precision electrical components?

Absolutely, its stable resistivity is great for resistors and sensors.

Is CuNi alloy cost-effective for long-term use?

Yes, its durability and performance make it a budget-friendly choice over time.

Comparison Parameters Table

-

Nickel Plated Motor Winding Copper Wire CuNi Alloy 0.012mm-1.0mm Copper Magnet Cable Wire

Enquire Now -

DLX Low Resistance CuNi15 Nickel Copper Alloy Wire

Enquire Now -

Low Resistance Anti-Oxidation 0.03Mm~8Mm CuNi Wire New Constantan Wire Copper Nickel Alloy

Enquire Now -

New Constantan Copper Nickel Alloy Resistance Wire For Sale

Enquire Now