CuNi Alloy The Ultimate Choice for High-Temperature and Corrosive Environments

- Product Details

Our CuNi alloy is a total rockstar, and we’re thrilled to show why it’s the ultimate choice for tackling high-temperature and corrosive environments. This copper-nickel alloy is built to deliver top-notch performance in some of the toughest conditions out there, from salty seas to chemical plants.

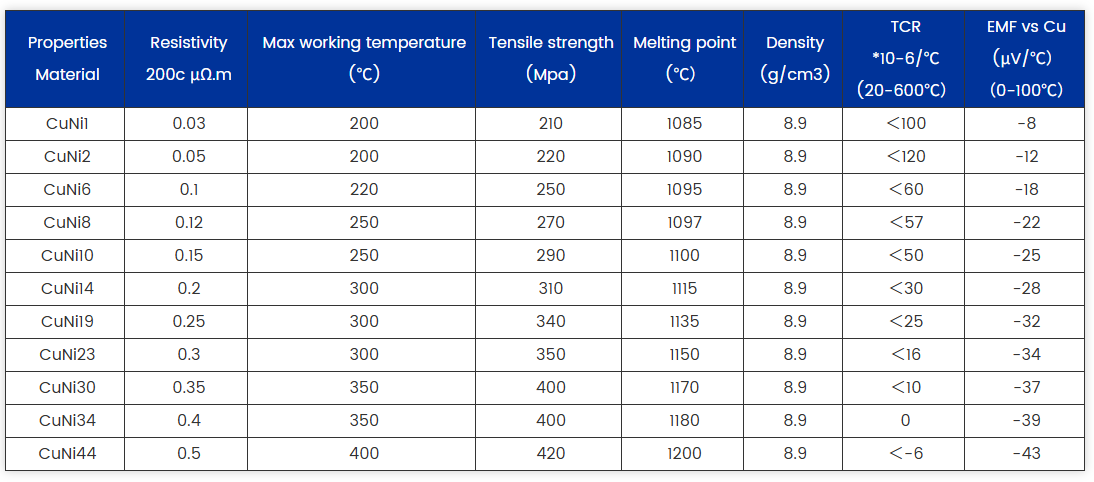

CuNi alloys, ranging from low-nickel grades like CuNi1 (~1% nickel) to high-nickel ones like CuNi44 (~44% nickel), are designed to handle temperatures up to 400°C with ease. Their corrosion resistance is next-level, especially in marine or acidic settings, thanks to a protective oxide layer that keeps rust at bay. Whether it’s CuNi10 for heating cables or CuNi44 for precision resistors, these alloys shine in harsh environments. With electrical resistivity between 0.10 and 0.49 µΩ·m, they offer stable performance for heating and electrical systems.

The thermal conductivity, ranging from 30 to 50 W/mK, makes CuNi awesome for quick, even heat distribution, perfect for applications like heat exchangers or low-power heating elements. With tensile strength of ~300-400 MPa, it’s durable enough for long-term use, and its high formability lets us craft it into wires, tubes, or flat strips for custom designs. Manufacturers love how easy it is to work with, whether for intricate components or heavy-duty setups.

The industry in 2025 is all about durability and sustainability, and our CuNi alloy is right on trend. There’s a huge demand for corrosion-resistant, cost-effective materials in marine, chemical, and renewable energy sectors. Being 100% recyclable, it’s a perfect fit for eco-friendly manufacturing. As compact, high-efficiency systems like offshore wind turbines or electric vehicle components keep trending, CuNi’s versatility and reliability make it a top pick.

Sure, Nichrome Cr20Ni80 can handle way higher temperatures, but CuNi’s lower cost and better corrosion resistance in wet environments make it unbeatable for moderate-heat applications. Stainless Steel 316 is tough but pricier and less conductive. Just keep CuNi away from extreme high-heat setups, though it thrives in most corrosive conditions like a pro.

From marine heat exchangers to precision heating systems, our CuNi alloy delivers the corrosion resistance, heat performance, and value that keep industries running strong in the toughest environments.

Support and Services:

CuNi alloy is a highly versatile material used in a wide range of applications. Our technical support team is available to help you with any questions you may have regarding the use, properties, and characteristics of CuNi alloy. We offer a variety of services to support your needs, including: - Material selection guidance - Custom alloy development - Testing and analysis services - Technical consulting Our experienced team of engineers and metallurgists can assist you with any technical challenges you may face, and our state-of-the-art facilities are equipped to handle a range of testing and analysis needs. Contact us to learn more about how we can support your CuNi alloy needs.

Packing and Shipping:

Product Packaging:

Our CuNi alloy products are carefully packed to ensure their safety during transportation. They are usually packaged in wooden cases or pallets with proper cushioning materials to prevent any damage or scratches during transit.

Shipping:

We offer various shipping options to our customers depending on their location and requirements. We work with reliable shipping companies to ensure timely delivery of the products. We also provide tracking information so that our customers can monitor the status of their shipment.

About Us:

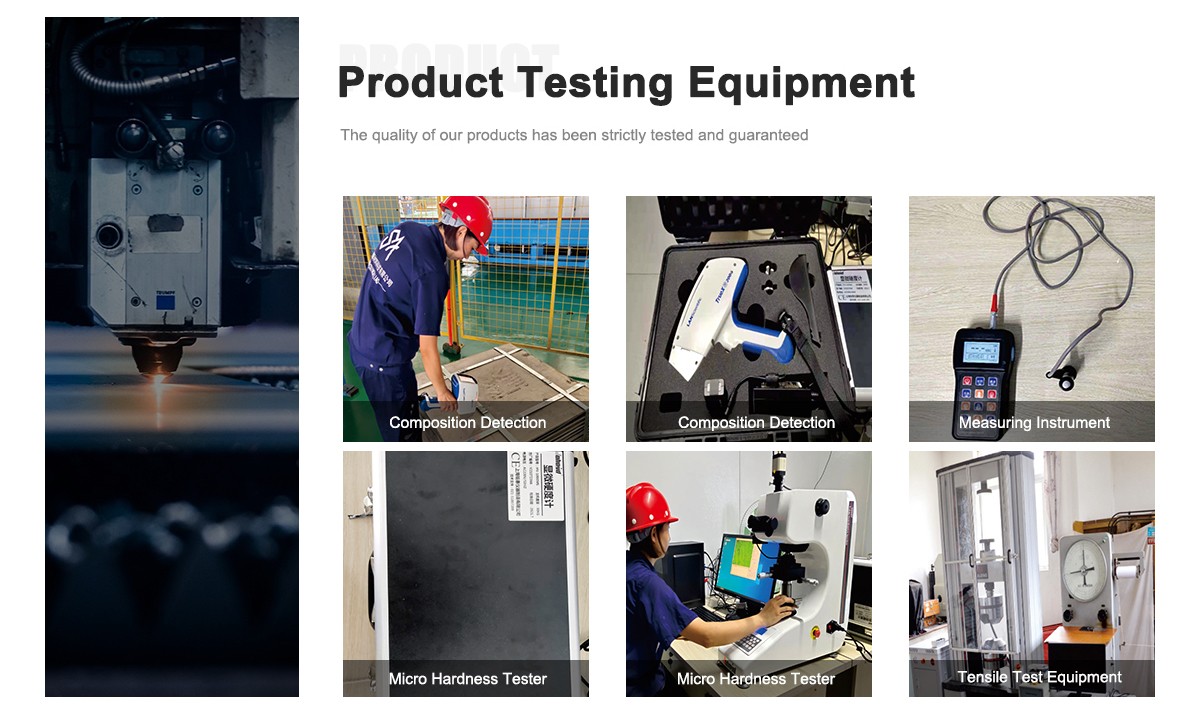

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why use CuNi alloy in corrosive environments?

Its superior corrosion resistance makes it perfect for harsh settings like marine or chemical industries.

How does CuNi alloy perform at high temperatures?

It’s stable up to 400°C, ideal for moderate-heat applications in tough conditions.

What’s the difference between CuNi grades like CuNi10 and CuNi44?

Higher nickel content (e.g., CuNi44) boosts heat resistance and resistivity but increases cost.

Can CuNi alloy be used in heating elements?

Yup, its stable resistivity and thermal conductivity make it great for low-to-moderate heat systems.

Is CuNi alloy corrosion-resistant in saltwater?

Totally, it’s a go-to for marine applications thanks to its protective oxide layer.

Is this alloy recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can CuNi alloy be shaped into custom designs?

Absolutely, its formability is perfect for wires, tubes, or flat components.

Is CuNi alloy cost-effective for industrial use?

Yes, it balances performance and affordability for high-corrosion environments.

-

Nickel Plated Motor Winding Copper Wire CuNi Alloy 0.012mm-1.0mm Copper Magnet Cable Wire

Enquire Now -

DLX Low Resistance CuNi15 Nickel Copper Alloy Wire

Enquire Now -

Low Resistance Anti-Oxidation 0.03Mm~8Mm CuNi Wire New Constantan Wire Copper Nickel Alloy

Enquire Now -

New Constantan Copper Nickel Alloy Resistance Wire For Sale

Enquire Now