Factory Direct Supply Hard 0.03mm 400 MPA CuNi34 Resistance CuNi Alloy Wire

- Product Details

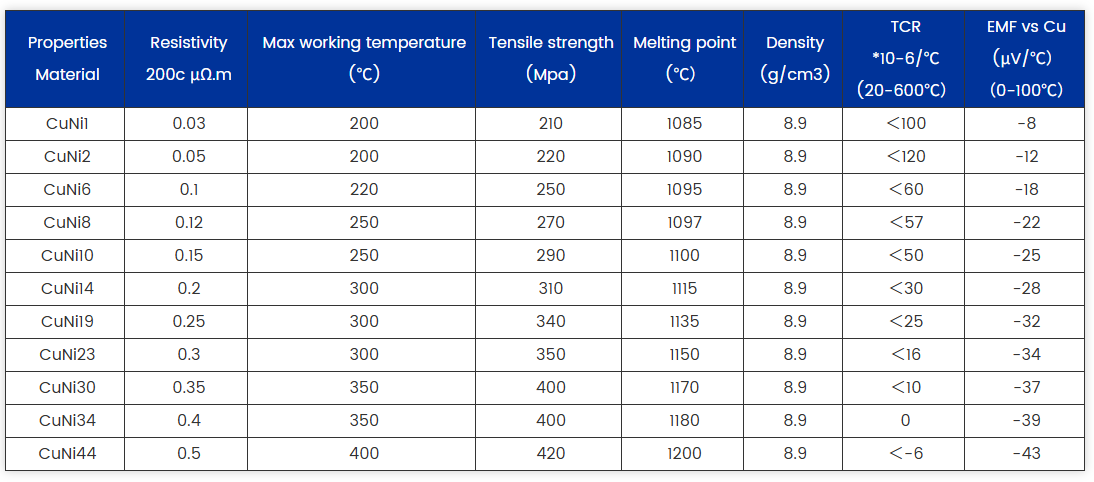

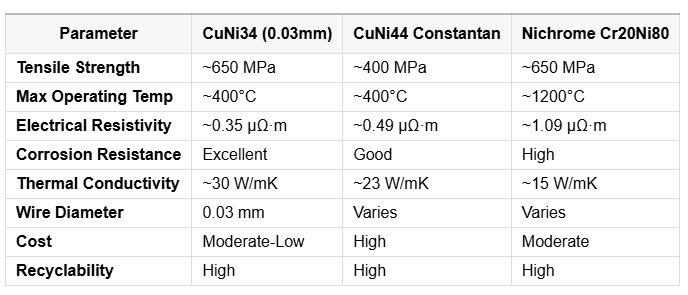

Our hard 0.03mm CuNi34 resistance alloy wire, with a solid 400 MPa strength, is a stellar pick for precision manufacturing, and we’re thrilled to show off what it can do. This ultra-fine copper-nickel alloy wire is designed for applications where accuracy, durability, and cost-efficiency are key, straight from our factory to you.

CuNi34, with ~34% nickel and the rest copper, is a reliable performer with a max operating temperature of 400°C—perfect for moderate-heat setups. Its corrosion resistance is top-notch, especially in humid or marine environments, thanks to a protective oxide layer that keeps it strong over time. The 0.03mm diameter makes it one of our finest wires, ideal for tight, high-precision designs like miniature resistors, thermocouples, or small-scale heating elements. With a tensile strength of ~400 MPa, it’s tough enough to handle stress without deforming.

The electrical resistivity, around 0.35 µΩ·m, is super stable, ensuring consistent performance in precision circuits or sensors. Its thermal conductivity (~30 W/mK) helps manage heat efficiently, making it great for applications needing quick response times. We can coil or shape it into intricate configurations, which is a big plus for manufacturers working on delicate electronics or precision instruments.

The industry in 2025 is all about miniaturization and sustainability, and our CuNi34 wire is right in the sweet spot. There’s a growing demand for compact, high-precision components in electronics, automotive sensors, and medical devices. Being 100% recyclable, it’s a great fit for eco-friendly manufacturing trends. As IoT devices and precision automation keep trending, this wire’s fine gauge and stable properties make it a top choice for cost-effective, high-quality production.

Sure, Nichrome Cr20Ni80 can handle much higher temperatures, but CuNi34’s lower resistivity and affordability make it ideal for moderate-heat, precision applications. CuNi44 Constantan has similar uses but higher nickel content increases costs. Just keep CuNi34 away from extreme high-heat environments, though it handles most conditions like a pro.

From tiny resistors to compact heating coils, our factory-direct 0.03mm CuNi34 wire with 400 MPa strength delivers the precision, durability, and value that keep manufacturers ahead of the curve.

Composition and General Properties:

CuNi34:

Composed of approximately 34% nickel and 66% copper.

Known for high electrical resistivity and stability over a wide range of temperatures.

Often used in electrical and electronic applications due to its resistance properties.

Specific Features:

Hard Condition:

The term "hard" indicates that the material has been cold-worked to increase its hardness and tensile strength. This makes it less ductile but more resistant to deformation.

0.03mm Thickness:

Extremely thin, suggesting use in applications requiring precise and delicate materials.

Typically utilized in thin film or wire forms where space and material efficiency are crucial.

400 MPa:

Tensile strength of 400 MPa indicates a high level of mechanical strength, enabling the material to withstand significant stress and strain without breaking.

This property is critical for applications where the material must maintain its integrity under load.

Applications:

Given these properties, a "Hard 0.03mm 400 MPa CuNi34 Resistance CuNi Alloy" would be well-suited for applications such as:

Precision Resistors:

Ideal for manufacturing thin-film precision resistors used in electronic circuits where exact resistance values are necessary.

Heating Elements:

Suitable for use in micro-heating elements, where the thinness and high resistivity of the material allow for precise control of heating.

Electronic Components:

Used in the production of various electronic components, such as connectors, where small size and high reliability are important.

Instrumentation:

Employed in sensitive instrumentation and measurement devices, where stability and accuracy over a range of temperatures are crucial.

Strain Gauges:

Utilized in strain gauges due to its consistent electrical resistance under mechanical deformation, allowing for precise measurement of strain.

Medical Devices:

Potential applications in medical devices that require biocompatible materials with stable electrical properties.

Sensors:

Used in various types of sensors that require materials with stable and predictable electrical characteristics.

About Us:

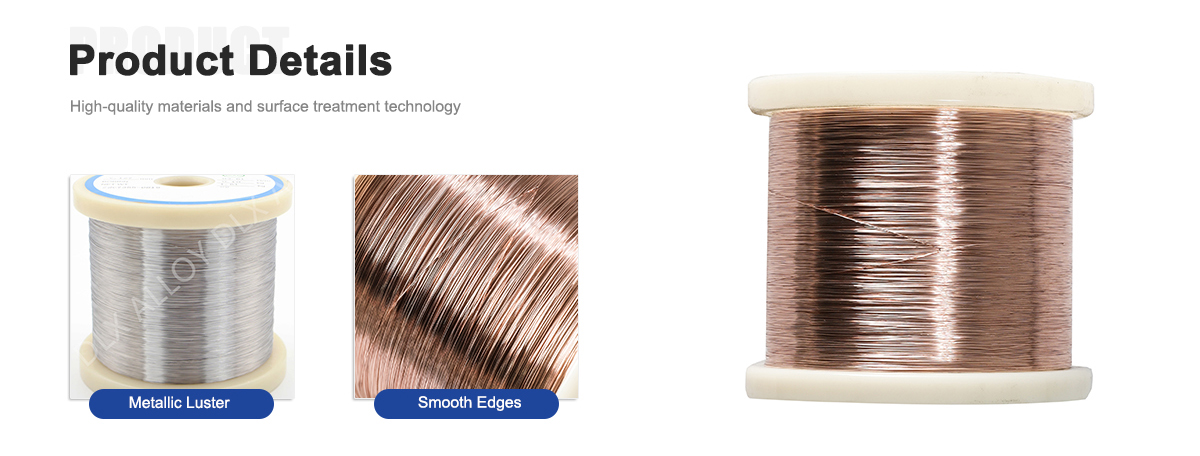

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why use 0.03mm CuNi34 wire for resistance applications?

Its ultra-thin size and stable resistivity make it perfect for precise, compact resistance systems.

How does CuNi34 compare to CuNi44 Constantan?

CuNi34 has lower nickel content, offering cost savings while maintaining good resistivity.

Can this wire handle high temperatures?

Yup, it’s stable up to 400°C, suitable for moderate heat applications.

Is 0.03mm CuNi34 wire corrosion-resistant?

Totally, it resists corrosion well, especially in humid or marine environments.

What’s the benefit of its 400 MPa strength?

It ensures durability and resistance to deformation in high-stress setups.

Is this CuNi34 wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be used in small-scale electronics?

Absolutely, its fine gauge is ideal for miniature resistors and circuits.

Is 0.03mm CuNi34 wire cost-effective?

Yes, it balances performance and precision at a budget-friendly price.

-

Nickel Plated Motor Winding Copper Wire CuNi Alloy 0.012mm-1.0mm Copper Magnet Cable Wire

Enquire Now -

DLX Low Resistance CuNi15 Nickel Copper Alloy Wire

Enquire Now -

Low Resistance Anti-Oxidation 0.03Mm~8Mm CuNi Wire New Constantan Wire Copper Nickel Alloy

Enquire Now -

New Constantan Copper Nickel Alloy Resistance Wire For Sale

Enquire Now