Low Resistance CuNi Electric Resistance Wire CuNi Heating Wire

- Product Details

Product name:CuNi Wire Material:Copper Nickel Alloy Size:Customized Size Usage:Heating Product Nickel(Min):44% Resistivity:0.5μΩ·cm Tensile Strength:420 MPA Density:8.9 g/cm³ Condition:Hard / Soft Melting Point:1100℃.

Copper-nickel alloy is an important type of alloy material, usually composed of copper (Cu) and nickel (Ni) in different proportions. These alloys are known for their excellent electrical conductivity, corrosion resistance, and mechanical properties and are therefore widely used in various industrial applications.

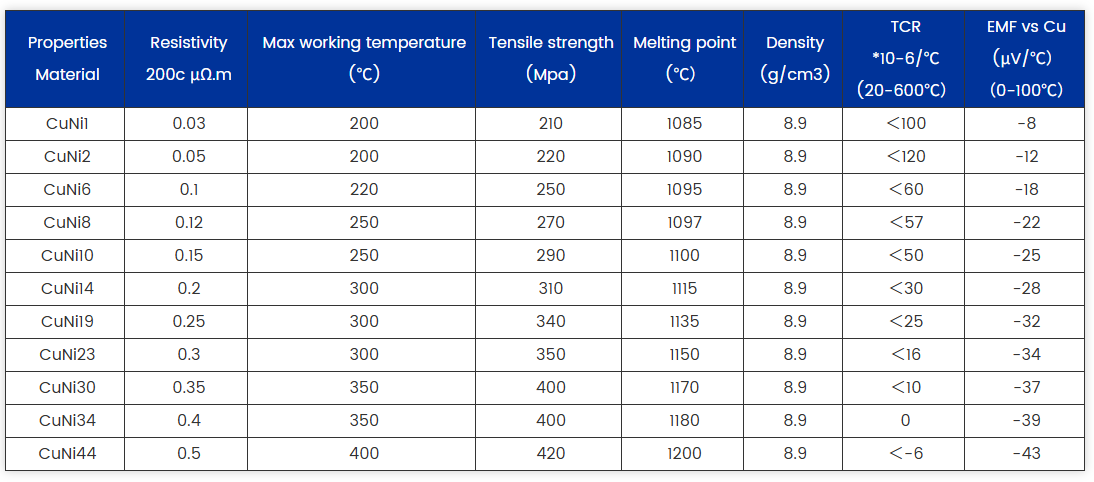

Common grades of CuNi alloys include CuNi1, CuNi2, CuNi10 and CuNi44. These grades represent different alloy compositions and performance characteristics. For example, CuNi1 and CuNi2 are typical low-copper alloys with higher copper content and are suitable for applications requiring higher electrical conductivity. CuNi10 and CuNi44 are alloys with higher nickel content, higher corrosion resistance and heat resistance, and are suitable for use in high temperature environments.

In addition, CuNi alloy also has some special alloy models, such as 6J8, 6J11 and 6J13, etc. They usually refer to alloys that meet specific standards or design requirements. These alloys may have specific thermal expansion coefficients, resistivities, and other properties that can be used in applications such as temperature sensors, resistors, and more.

The parameters of CuNi alloy include its composition, physical properties and chemical properties. Generally speaking, the composition of CuNi alloys can be adjusted according to specific grades and application requirements to achieve different performance goals. In terms of physical properties, CuNi alloys usually have good processability, weldability and heat treatability, and can be processed and adjusted as needed. In terms of chemical properties, CuNi alloy has good corrosion resistance and can work stably for a long time in a variety of environments.

Our low resistance CuNi electric resistance heating wire is a total winner, and we’re stoked to share why it’s such a hit for heating applications. This copper-nickel alloy wire is all about delivering efficient, reliable heat without costing a fortune, making it a go-to for a ton of industries.

CuNi, typically with nickel content ranging from 1% to 34% (like CuNi1 to CuNi34), is designed for low-to-moderate heat applications, handling temperatures up to 400°C with ease. Its corrosion resistance is killer, especially in wet or salty environments, thanks to a protective oxide layer that keeps it strong for years. The low electrical resistivity—anywhere from 0.10 to 0.35 µΩ·m depending on the alloy—means it conducts electricity super efficiently, perfect for heating systems where you want to save on power.

With a tensile strength of ~300-400 MPa, this wire is tough enough for everyday use, and its high thermal conductivity (30-50 W/mK) ensures quick, even heat distribution. Its formability is a big plus—we can shape it into coils, flat wires, or custom designs for anything from household appliances like toasters to industrial heating cables. It’s super versatile and easy to work with, which manufacturers love.

The industry in 2025 is buzzing with demand for cost-effective, sustainable materials, and our CuNi heating wire is right on trend. Sectors like consumer electronics, automotive, and marine applications are all about affordable, corrosion-resistant components that perform reliably. Being 100% recyclable, this wire fits perfectly with eco-friendly manufacturing goals. As low-power, compact heating systems keep gaining traction, CuNi’s low resistance and high conductivity make it a top pick for efficient designs.

Sure, Nichrome Cr20Ni80 can handle way higher temperatures, but CuNi’s lower cost and better conductivity make it ideal for moderate-heat applications. CuNi44 Constantan has similar temperature limits but higher resistivity, which can mean less efficiency for some setups. Just keep CuNi away from extreme high-heat environments, though it thrives in most conditions like a pro.

From home heaters to marine electrical systems, our low resistance CuNi heating wire delivers the efficiency, durability, and value that keep manufacturers and end-users happy.

Feature

Excellent electrical conductivity properties: Copper-nickel alloys are favored for their good electrical conductivity properties. Its electrical conductivity is close to that of pure copper, making it an important material in the field of electrical engineering.

Good corrosion resistance: Copper-nickel alloy has excellent corrosion resistance and can work stably for a long time in a variety of harsh environments, which makes it widely used in marine engineering, chemical industry and other fields.

Excellent mechanical properties: Copper-nickel alloy has good mechanical properties, including strength, hardness and toughness. This makes it suitable for the manufacture of various mechanical parts and structural parts.

Good thermal stability: Copper-nickel alloy is stable in high-temperature environments and has good heat resistance, and can be used in the manufacturing of high-temperature processes and high-temperature equipment.

Good processability: Copper-nickel alloys are easy to process into various shapes and can be processed by forging, rolling, drawing and other methods, making them have broad application prospects in industrial production.

Corrosion resistance

Seawater corrosion resistance: Copper-nickel wire is particularly suitable for marine environments and can resist corrosion from salty and sulfur-containing substances in seawater. Therefore, it is widely used in ships, ocean platforms, seawater desalination equipment, etc.

Resistant to chemical media: Copper-nickel wire has good corrosion resistance to a variety of chemical media, including acidic, alkaline and neutral solutions, and is suitable for use in the chemical industry.

Oxidation resistance: Copper-nickel wire can maintain good corrosion resistance at high temperatures, and its oxidation resistance makes it perform well in high-temperature applications.

Resistant to pitting corrosion and stress corrosion: The alloy composition of copper-nickel wire gives it the ability to resist pitting corrosion and stress corrosion, which is very important in many demanding applications.

Self-healing ability: The passivation film formed on the surface of the copper-nickel wire can repair itself after being damaged and continue to maintain its corrosion resistance.

Long-term stability: Copper-nickel wire can maintain its corrosion resistance during long-term use and is not prone to performance degradation.

Environmental adaptability: Copper-nickel wire can maintain its corrosion resistance under a variety of environmental conditions, including temperature changes, pressure changes, etc.

The high corrosion resistance of copper-nickel wire mainly benefits from the following points:

Addition of nickel: Nickel is an excellent corrosion-resistant element. When added to copper, it can significantly improve the corrosion resistance of the alloy, especially in salty environments such as seawater.

Solid solution structure: Copper-nickel alloy forms a continuous α-single-phase solid solution. This structure prevents the alloy from phase change during hot and cold processing and maintains consistent corrosion resistance.

Passivation performance: A dense passivation film is easily formed on the surface of copper-nickel alloy. This film can effectively isolate the contact between the alloy and the corrosive medium and improve its corrosion resistance.

Optimization of alloying elements: By adjusting other alloying elements (such as iron, manganese, zinc, etc.) and their proportions in the copper-nickel wire, the corrosion resistance can be further optimized.

Processing technology: Appropriate heat treatment and processing technology can enhance the corrosion resistance of copper-nickel alloys. For example, cold working can improve its strength and corrosion resistance.

Application

Electrical Engineering: Due to its excellent conductive properties, copper-nickel wire is often used in the manufacture of electrical components such as wires, cables, resistors, and inductors.

Marine Engineering: Due to its excellent corrosion resistance, copper-nickel alloy is often used in the manufacturing of pipelines, valves, ship equipment and other components in marine environments.

Chemical industry: Copper-nickel wire is often used in the chemical industry to manufacture corrosion-resistant equipment, reactors, heat exchangers, etc., and has good performance in highly corrosive media.

High temperature process: Due to its good heat resistance, copper-nickel alloy is widely used in high-temperature equipment and high-temperature processes, such as heat treatment furnaces, high-temperature heat exchangers, etc.

About Us:

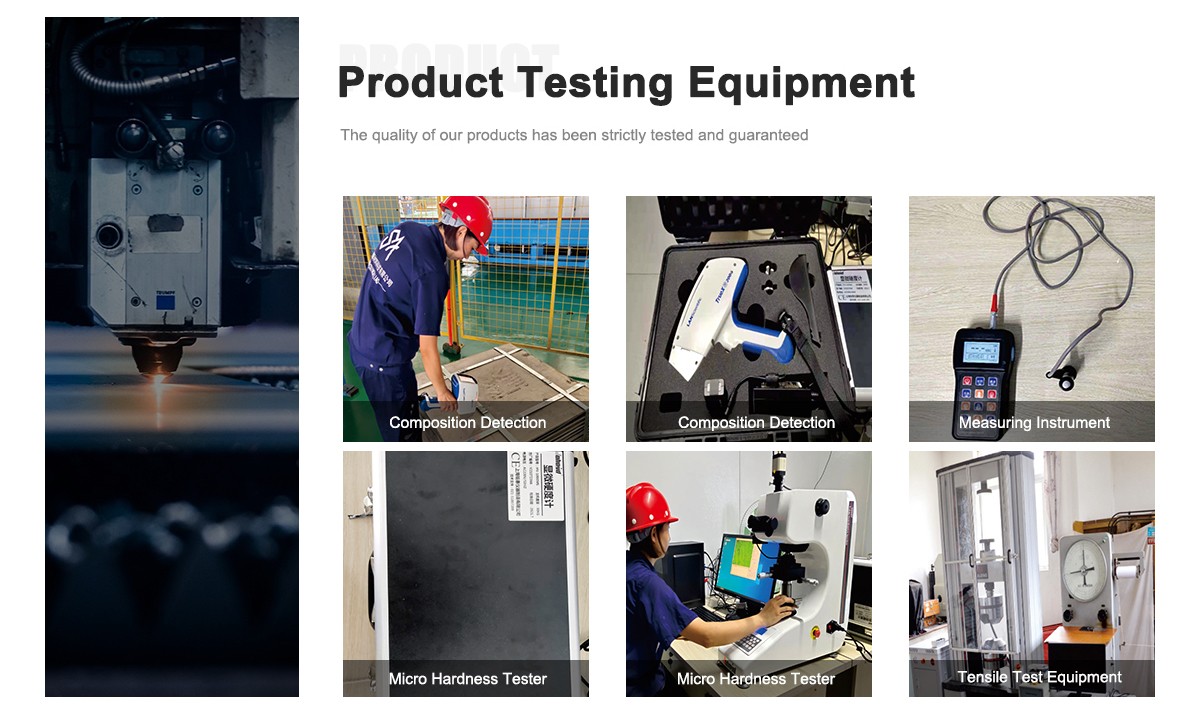

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why use CuNi heating wire for electrical applications?

Its low resistance and corrosion resistance make it perfect for efficient, reliable heating systems.

How does CuNi compare to Nichrome for heating?

CuNi has lower resistivity and cost but handles less heat than Nichrome’s high-temperature capabilities.

Can this wire handle moderate temperatures?

Yup, it’s stable up to 400°C, great for low-to-moderate heat applications.

Is CuNi wire corrosion-resistant?

Totally, it’s awesome in humid or marine environments, resisting rust like a champ.

What’s the benefit of its low resistance?

It allows for efficient power delivery, ideal for cost-effective heating setups.

Is this CuNi wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be used in household appliances?

Absolutely, its formability and low resistance are perfect for things like toasters or heaters.

Is CuNi heating wire budget-friendly?

Yes, it offers solid performance at a lower cost than high-nickel alloys.

-

Nickel Plated Motor Winding Copper Wire CuNi Alloy 0.012mm-1.0mm Copper Magnet Cable Wire

Enquire Now -

DLX Low Resistance CuNi15 Nickel Copper Alloy Wire

Enquire Now -

Low Resistance Anti-Oxidation 0.03Mm~8Mm CuNi Wire New Constantan Wire Copper Nickel Alloy

Enquire Now -

New Constantan Copper Nickel Alloy Resistance Wire For Sale

Enquire Now