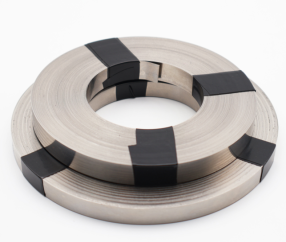

Instrument Springs made by 3J21/Elgiloy Wires

Release time:2026-02-25 Strike:1015 Inquire Now

Elastic Alloy 3J21

| Russia | China | USA | France | Japan |

| 40KHXM | 3J21 | Elgiloy | Phynox | NAS604PH |

3J21 Elastic Alloy Chemical Composition:

| Grade | C | S | P | Mn | Si | Ni | Cr | Ti | Al | Co | Mo | W | Fe |

| 3J21 | 0.07-0.12 | ≦0.01 | ≦0.01 | 1.7-2.3 | ≦0.6 | 14-16 | 19-21 | - | - | 39-41 | 6.5-7.5 | - | Bal |

Physical and Chemical Properties:

- The 3J21 alloy is a nickel-based superalloy, with the primary alloying elements being nickel, chromium, and titanium.

- It is characterized by its exceptional elastic properties, with a very high yield strength and excellent resistance to plastic deformation.

- The alloy has a density of around 8.3 g/cm³, which is slightly higher than some other high-performance alloys.

- 3J21 exhibits excellent corrosion and oxidation resistance, making it suitable for use in harsh environments.

- The alloy maintains its mechanical properties and performance even at elevated temperatures, up to around 600°C.

Density (g/cm3) | Resistivity at 20°C ųΩ•m | Elastic Modulus (E/MPa) | Poisson's Ratio (G/MPa) | Magnetic Frequency (K/106) |

| 8.3 | 0.92 | 196000-215500 | 73500-83500 | 50-1000 |

Production Method:

- 3J21 elastic alloy is typically produced using vacuum induction melting or vacuum arc remelting processes.

- These methods allow for precise control over the alloy composition and impurity levels, ensuring consistent quality.

- After the initial melting, the alloy may undergo various thermomechanical processing steps, such as forging, rolling, or heat treatment, to optimize its microstructure and mechanical properties.

3J21 Production Process-Hot Rolled

Applications:

- The 3J21 elastic alloy is widely used in the aerospace industry, particularly in the manufacture of high-performance springs, diaphragms, and other components that require exceptional elastic properties.

- It is also employed in the production of precision instruments, medical devices, and various industrial applications where the ability to withstand high stresses and deformations is crucial.

- Due to its corrosion resistance and high-temperature performance, the 3J21 alloy is sometimes used in chemical processing equipment and power generation systems.

Advantages of 3J21 Elastic Alloy:

1. Exceptional Elastic Properties:

- The 3J21 alloy has an exceptionally high yield strength, often exceeding 1200 MPa, combined with excellent resistance to plastic deformation.

- This allows the alloy to store and release large amounts of elastic energy, making it ideal for applications that require high-performance springs and other elastic components.

2. Corrosion and Oxidation Resistance:

- The 3J21 alloy exhibits excellent resistance to corrosion and oxidation, enabling its use in harsh environments where exposure to corrosive substances or high temperatures is a concern.

- This property helps extend the service life of components made from the 3J21 alloy, reducing maintenance and replacement costs.

3. High-Temperature Performance:

- The 3J21 alloy can maintain its exceptional mechanical properties at elevated temperatures, up to around 600°C.

- This thermal stability is crucial in applications where components are subjected to high operating temperatures, such as in aerospace and power generation industries.

4. Versatile Applications:

- The combination of exceptional elastic properties, corrosion resistance, and high-temperature performance makes the 3J21 alloy a versatile material suitable for a wide range of industrial and engineering applications.

- From aerospace components to precision instruments, the 3J21 alloy can be utilized in demanding environments where superior material properties are required.

The 3J21 elastic alloy is a high-performance superalloy that offers exceptional elastic behavior, thermal stability, and corrosion resistance, making it a valuable material in industries that require advanced engineering solutions.

-

3J40 elastic alloy used to make the shaft tip of instruments and meters

3J40 Elastic Alloy Chemical Composition...

-

Ni-Span C902/3J53 Elastic Alloy

Precision Alloy-3J533J53 Alloy is the name in the Chinese Standa...

-

High Elastic Alloy Strip 3J01 / ЭИ702 / 36HXTЮ

What is 3J01 Elastic Alloy?3J01 precision alloy is an iron-nicke...