0Cr21Al6Nb High Resistance Alloy Wire with Addition of Nb element

- Product Details

FeCrAl -made Grade 216Nb(0Cr21Al6Nb)) resistance alloy is characterized by high resistivity, low resistance coefficient, high operating temperature, good oxidation resistance under high temperature, and a maximum applicable temperature of 1250℃.

The Role of Niobium/Columbium (Nb/Cb) in FeCrAl Alloys

Niobium and columbium often coexist with tantalum, and their roles in alloys are similar. Niobium and tantalum partially dissolve into the solid solution, contributing to solid solution strengthening.

When dissolved in austenite, they significantly improve the alloy's hardenability. However, when present as carbide and oxide particles, they refine the grain size and reduce the alloy's hardenability.

They can increase the alloy's tempering stability and have a secondary hardening effect. Trace amounts of niobium can enhance the alloy's strength without affecting its plasticity or toughness.

Due to the grain refinement effect, niobium can improve the alloy's impact toughness and lower its brittle transition temperature.

When the niobium content is more than eight times the carbon content, it can almost completely fix all the carbon in the alloy, providing excellent hydrogen resistance.

In austenitic alloys, niobium can prevent intergranular corrosion caused by oxidizing media. Due to its ability to fix carbon and its precipitation-hardening effect, niobium can enhance the high-temperature properties of heat-resistant alloys, such as creep strength.

In summary, the Nb element in FeCrAl alloy can improve its impact toughness, lower brittle transaction temperature, and enhance creep strength.

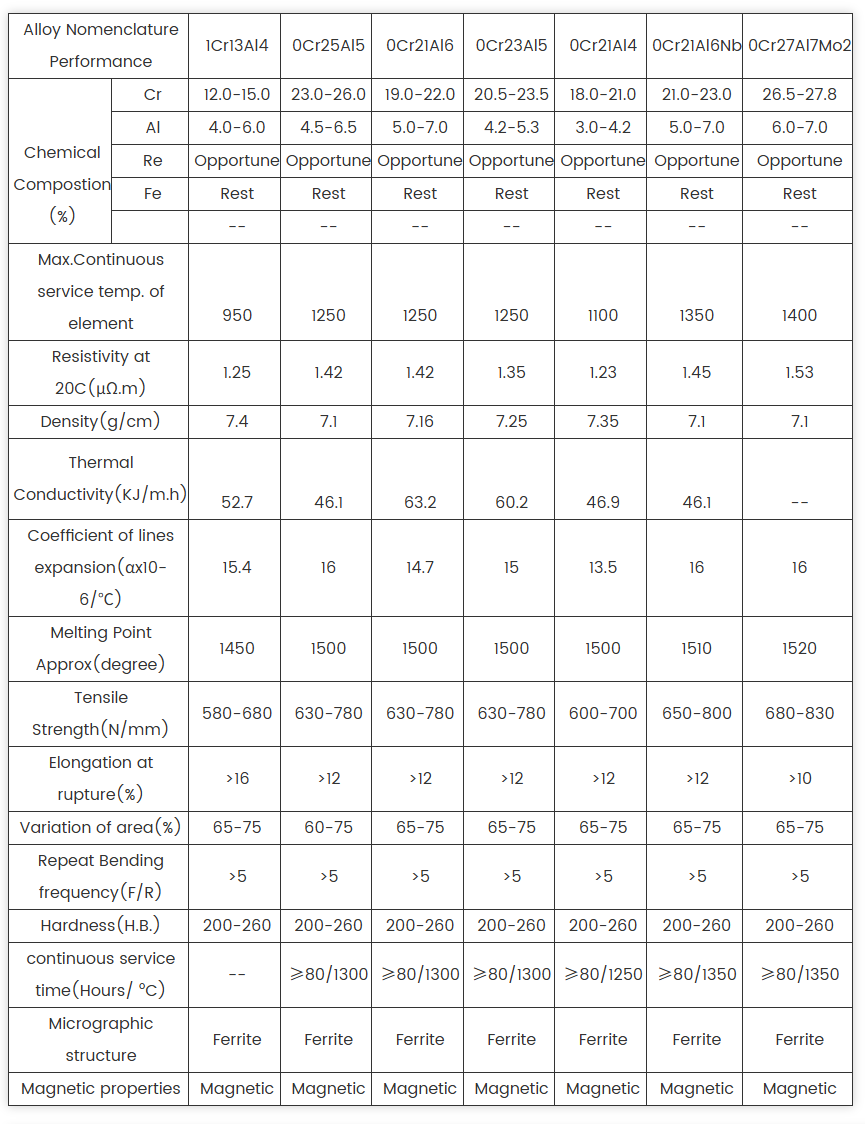

Key Properties of Grade 216Nb

For more details, pls directly contact us.

About Us:

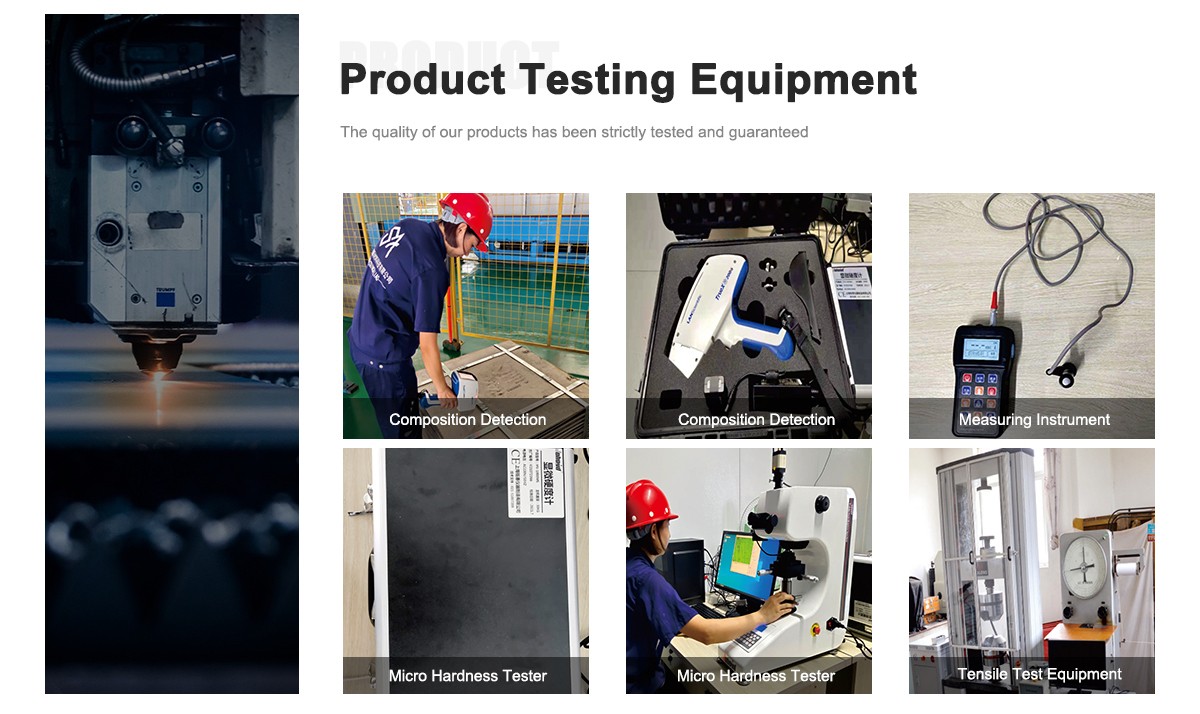

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

-

Bright Annealed FeCrAl Alloy with Excellent Oxidation Resistance and Tensile Strength 700MPA

Enquire Now -

Chromium Cast Iron Bar for Corrosion and Oxidation Resistance

Enquire Now -

FeCrAl Alloy Bar with Excellent Corrosion Resistance for Extreme Conditions

Enquire Now -

1250C-1500C Iron Chromium Melting Point chromium aluminum Strip for Superior Resistance and Welding

Enquire Now