FeCrAl Alloy The Top-Notch Alloy for High-Temperature Heating Applications

- Product Details

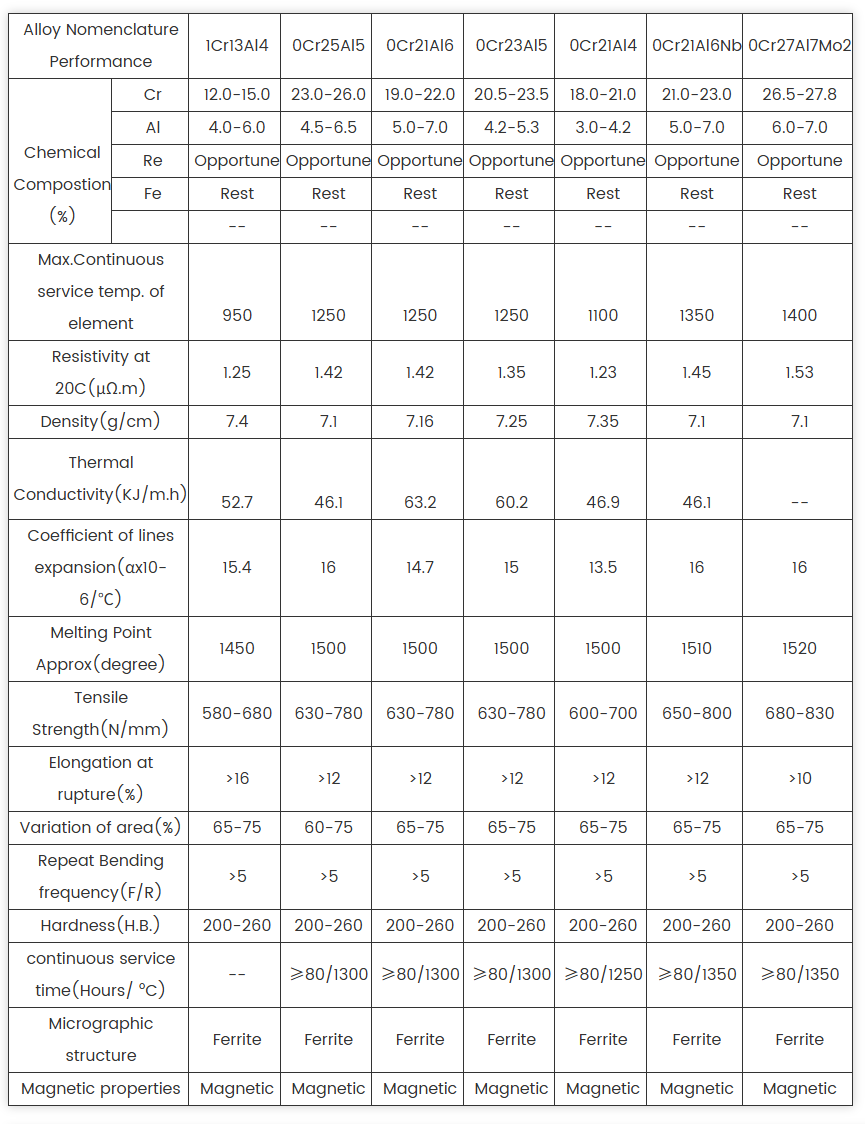

Our FeCrAl alloy is the gold standard for manufacturers needing a reliable, high-performance material for heating applications in extreme environments. Composed of iron, 20-30% chromium, and 4-6% aluminum, this alloy is built to withstand blistering temperatures while delivering efficiency and durability at a price that makes sense.

What makes FeCrAl stand out? Its ability to operate at temperatures up to 1400°C is a game-changer. The alloy forms a tough aluminum oxide layer that protects against oxidation, ensuring long-term performance in industrial furnaces, kilns, and household appliances like toasters and ovens. With a high resistivity of 1.2-1.5 µΩ·m and a low temperature coefficient of resistance, it’s perfect for heating elements that need to maintain consistent performance under intense heat. Its creep resistance also means it holds its shape under thermal stress, making it a go-to for heavy-duty applications.

The alloy’s mechanical properties are solid, with a tensile strength of 600-800 MPa and hardness of 200-260 HV, giving it the toughness needed for high-stress environments. While its elongation (15-25%) is slightly lower than NiCr alloys, it’s still weldable and can be formed into wires, strips, or custom components, though machining requires specialized tools due to its hardness. Compared to NiCr, FeCrAl is more cost-effective because of its lower nickel content, offering similar high-temperature performance without the premium price tag.

The high-temperature alloy market is growing at a steady 5-6% CAGR, driven by demand in industrial manufacturing, aerospace, and ceramics. With industries pushing for energy-efficient heating systems and durable components, FeCrAl’s ability to handle extreme temperatures and resist oxidation makes it a top pick. Unlike CuNi44, which maxes out at 600°C, FeCrAl thrives in applications requiring sustained high heat, like ceramic kilns or aerospace furnace parts.

We produce our FeCrAl alloy with strict quality controls to ensure consistent resistivity, strength, and surface quality, making it ready for OEM applications. We’re also exploring sustainable practices, like recycling, to keep our process eco-friendly. While raw material prices can fluctuate, FeCrAl’s long lifespan and low maintenance costs make it a budget-friendly choice for high-performance heating systems.

In short, our FeCrAl alloy is your go-to for high-temperature heating applications. Whether you’re building industrial furnaces, appliance heating elements, or aerospace components, it delivers the heat resistance, efficiency, and durability you need to get the job done right.

Product Description:

One of the key features of the FeCrAl alloy is its high tensile strength, which ranges from 630-780MPA. This makes it an ideal material for applications that require high strength and durability, such as in heating elements, furnace components, and industrial heating systems.

In addition to its strength, the FeCrAl alloy also has a high level of elongation, which is ≥25%. This means that it has the ability to stretch and deform without breaking, making it a versatile material for various applications.

The melting point of the FeCrAl alloy is between 1250℃-1500℃, which is relatively high compared to other metals and alloys. This makes it suitable for use in high-temperature environments such as in furnaces and heating systems.

The FeCrAl alloy can also be subjected to different types of heat treatment, including bright, oxided, and acide treatments. This allows it to be tailored to different applications and environments, enhancing its performance and longevity.

Another important characteristic of the FeCrAl alloy is its ferromagnetic property, which means that it has a strong magnetic field. This makes it an ideal material for applications that require magnetic properties, such as in electrical motors and generators.

Overall, the FeCrAl alloy is a versatile and durable material that is widely used in various industries due to its excellent mechanical and physical properties. Its high tensile strength, elongation, melting point, and magnetic properties make it an ideal material for a wide range of applications.

Features:

Product Name: FeCrAl Alloy

Tensile Strength: 630-780MPA

Formability: Excellent

Condition: Hard / Soft

Material: FeCrAl Alloy

Heat Treatment: Bright, Oxided, Acide

FeCrAl Alloy, also known as high chrome iron, is a material with excellent formability and a tensile strength of 630-780MPA. It is available in both hard and soft conditions and can be heat treated using bright, oxided or acide methods.

For more details, pls directly contact us.

Applications:

One of the most common applications of DLX FeCrAl alloy is in the manufacturing of heating elements, such as resistohm 135. These heating elements are used in industrial furnaces, ovens, and other high-temperature applications. DLX FeCrAl alloy has high electrical resistance, which makes it an ideal material for these types of applications.

The DLX FeCrAl alloy is available in both hard and soft conditions, which makes it suitable for different types of applications. The soft condition is used for applications that require flexibility and the hard condition is used for applications that require high strength and durability.

The DLX FeCrAl alloy is manufactured in China, JiangSu. This ensures that the product meets high-quality standards and is produced using the latest manufacturing techniques.

DLX FeCrAl alloy has excellent corrosion resistance, which makes it suitable for use in harsh environments. It can withstand high temperatures, which means it can be used in high-temperature applications without degrading or losing its properties.

The alloy has an elongation of ≥25% and tensile strength of 630-780MPA, which means it has excellent mechanical properties. These properties make it suitable for applications where high strength and durability are required.

DLX FeCrAl alloy is a versatile material that can be used in a variety of applications. It is commonly used in the production of heating elements for industrial furnaces, ovens and other high-temperature applications. It can also be used in the production of resistohm 135, which is a popular heating element used in the automotive industry.

In summary, DLX FeCrAl alloy is a high-quality, ferromagnetic electrical heating alloy with excellent resistance to oxidation and corrosion. It is available in both hard and soft conditions, making it suitable for different types of applications. DLX FeCrAl alloy is manufactured in China, JiangSu, ensuring that it meets high-quality standards. It has excellent mechanical properties and can be used in a variety of applications, including the production of resistohm 135 and other heating elements.

Support and Services:

Our FeCrAl alloy product technical support and services include:

Expert consultation on product selection and application

Custom alloy design and development

Material testing and analysis

Product performance evaluation and optimization

Technical training and education

Continuous improvement and innovation

Our team of experienced professionals is dedicated to providing the highest level of support and service to ensure the success of your applications with our FeCrAl alloy product.

Packing and Shipping:

Product Packaging:

The FeCrAl Alloy product will be carefully packaged in a sturdy cardboard box to prevent any damage during shipping. Each box will contain the product wrapped in bubble wrap or foam to ensure maximum protection. The box will also include a label indicating the product name, quantity, and any other necessary information.

Shipping:

The FeCrAl Alloy product will be shipped via a reliable carrier to ensure timely and safe arrival. The carrier will be selected based on the customer's preference or the most cost-effective option. Shipping fees will be calculated based on the destination and weight of the product.

About Us:

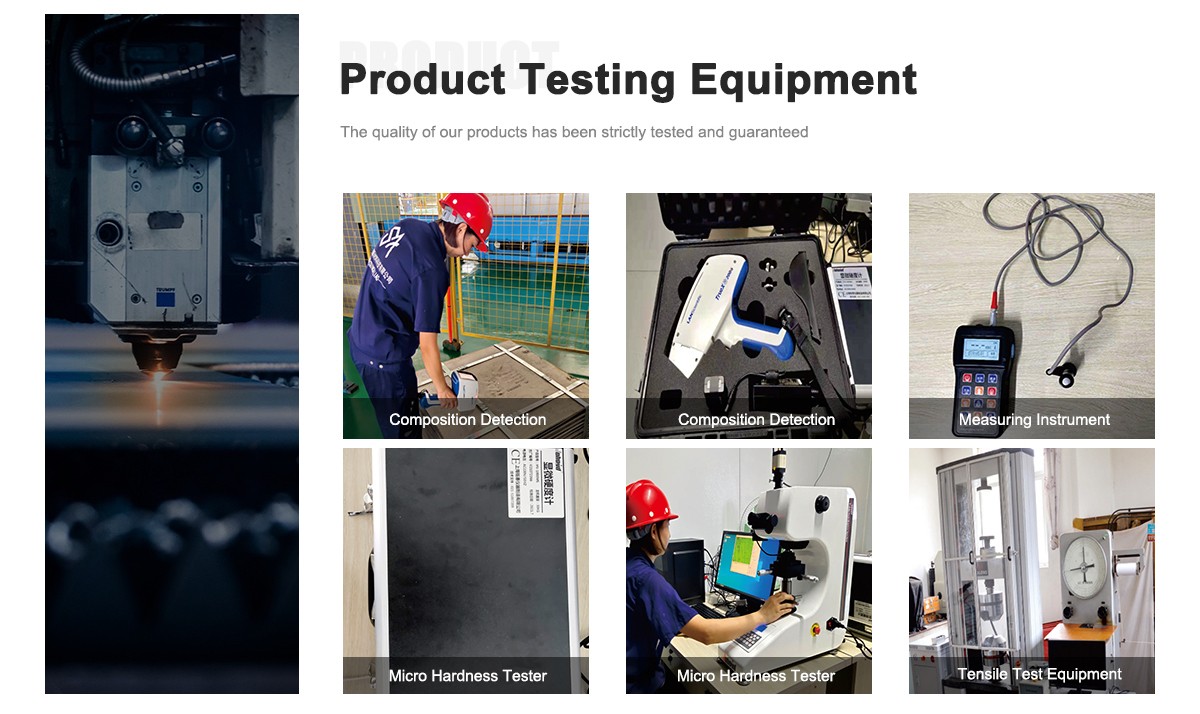

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What is FeCrAl alloy?

FeCrAl alloy, typically composed of iron, 20-30% chromium, and 4-6% aluminum, is known for high resistivity, oxidation resistance, and stability at temperatures up to 1400°C.

What are its primary applications?

It’s used in industrial furnaces, household appliances (e.g., toasters, ovens), kilns, and high-temperature heating elements due to its thermal stability and resistivity.

How does it perform in high-temperature environments?

It forms a protective aluminum oxide layer, allowing it to withstand temperatures up to 1400°C without significant degradation, ideal for continuous heating applications.

How does its resistivity compare to other alloys?

Its resistivity (~1.2-1.5 µΩ·m) is similar to NiCr (~1.0-1.5 µΩ·m) but higher than CuNi44 (~0.49 µΩ·m), making it excellent for heating elements.

How does it handle corrosion?

The aluminum oxide layer provides excellent oxidation resistance, but it’s less effective in sulfur-rich or reducing environments compared to NiCr alloys.

Which industries rely on FeCrAl alloy?

Electrical, industrial manufacturing, aerospace, and ceramics industries use it for heating elements, furnace components, and high-temperature applications.

Is it easy to process for manufacturing?

It has moderate ductility (15-25% elongation) and is weldable, but its high hardness (200-260 HV) requires specialized tools for machining and forming.

Is FeCrAl cost-effective?

Yes, it’s generally cheaper than NiCr alloys due to lower nickel content, offering similar high-temperature performance at a reduced cost.

-

Bright Annealed FeCrAl Alloy with Excellent Oxidation Resistance and Tensile Strength 700MPA

Enquire Now -

Chromium Cast Iron Bar for Corrosion and Oxidation Resistance

Enquire Now -

FeCrAl Alloy Bar with Excellent Corrosion Resistance for Extreme Conditions

Enquire Now -

1250C-1500C Iron Chromium Melting Point chromium aluminum Strip for Superior Resistance and Welding

Enquire Now