FeCrAl Alloy Versatile and Robust Heating Material for Various Industrial Needs

- Product Details

Our FeCrAl alloy is a versatile and robust heating material, delivering top-tier performance across a wide range of high-temperature industrial applications. Composed of iron, 20-30% chromium, and 4-6% aluminum, this alloy is engineered to provide exceptional heat resistance, efficiency, and durability, making it a go-to solution for industries seeking reliable and cost-effective heating systems.

FeCrAl’s ability to withstand temperatures up to 1400°C is a standout feature, making it ideal for industrial furnaces, kilns, and heat treatment systems used in metallurgy, ceramics, glass production, and aerospace. The alloy forms a protective aluminum oxide layer during heating, offering superior oxidation resistance that ensures long-term reliability in oxidative environments. With a high resistivity of 1.2-1.5 µΩ·m and a low temperature coefficient of resistance, it’s perfectly suited for heating elements that deliver consistent and efficient energy transfer, whether in large-scale industrial ovens or household appliances like toasters and dryers.

The alloy’s mechanical properties are equally impressive. With a tensile strength of 600-800 MPa, hardness of 200-260 HV, and excellent creep and fatigue resistance, FeCrAl maintains structural integrity under intense thermal and mechanical stress, ensuring a long service life. Its moderate elongation (15-25%) allows it to be formed into wires, strips, or custom components, while weldability supports seamless integration into complex designs. Machining requires specialized tools due to its hardness, but this is a minor trade-off for its robustness.

The high-temperature alloy market is growing at a 5-6% CAGR, driven by demand in industrial manufacturing, electronics, and ceramics. FeCrAl’s superior temperature tolerance (1400°C vs. NiCr’s 1200°C) and lower cost due to minimal nickel content make it a preferred choice for cost-conscious projects. Compared to CuNi 44, which is limited to 600°C and better suited for seawater corrosion resistance, FeCrAl excels in high-heat oxidative environments, offering unmatched versatility for industrial heating needs.

We produce our FeCrAl alloy with stringent quality controls, ensuring consistent resistivity, strength, and surface finishes (e.g., bright annealed or oxidized). Available in various forms like wires, strips, or coils, it’s ready for OEM customization into heating elements or resistance components. We’re committed to sustainability, exploring recycling options to reduce environmental impact. Despite potential raw material price fluctuations, FeCrAl’s longevity and low maintenance costs make it a smart investment for industrial applications.

In short, our FeCrAl alloy is the versatile and robust heating material for various industrial needs. Whether you’re powering furnaces, kilns, or appliance heaters, it delivers the heat resistance, efficiency, and durability to meet your toughest demands.

Product Description:

This alloy is available in both hard and soft conditions, making it versatile for different applications. It has a tensile strength range of 630-780MPA, which makes it ideal for use in high-stress environments. The elongation rate of this alloy is ≥25%, which means it can bend or deform without breaking, making it a reliable material for various applications.

FeCrAl Alloy has a high melting point, which ranges between 1250℃-1500℃. This means it can withstand high temperatures without losing its shape or strength. This attribute makes it a popular choice for applications that require resistance to high temperatures, such as furnace heating elements and electric heaters.

The FeCrAl Alloy is a popular choice for various industries, including automotive, aerospace, and electrical. Its excellent weldability makes it ideal for welding applications, and its resistance to high temperatures and corrosion makes it a reliable material for various applications.

Features:

Product Name: FeCrAl Alloy

Melting Point: 1250℃-1500℃

Elongation: ≥25%

Weldability: Excellent

Density: 7.2-7.7g/cm3

Heat Treatment: Bright, Oxided, Acide

This FeCrAl Alloy product is also known as Resistohm 135 and is a high-quality alloy with excellent weldability and a melting point of 1250℃-1500℃. It has an elongation of at least 25% and a density of 7.2-7.7g/cm3. It can be heat treated in bright, oxided, or acide conditions.

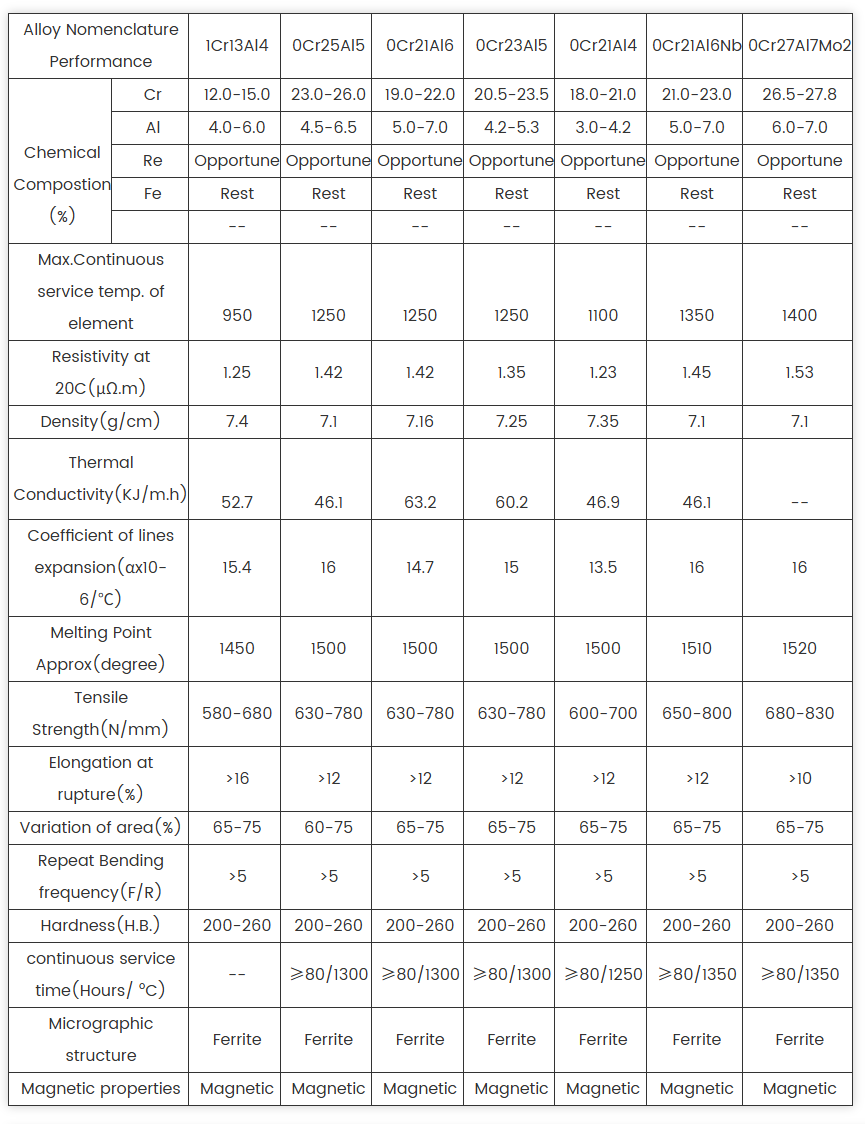

Technical Parameters:

For more details, pls directly contact us.

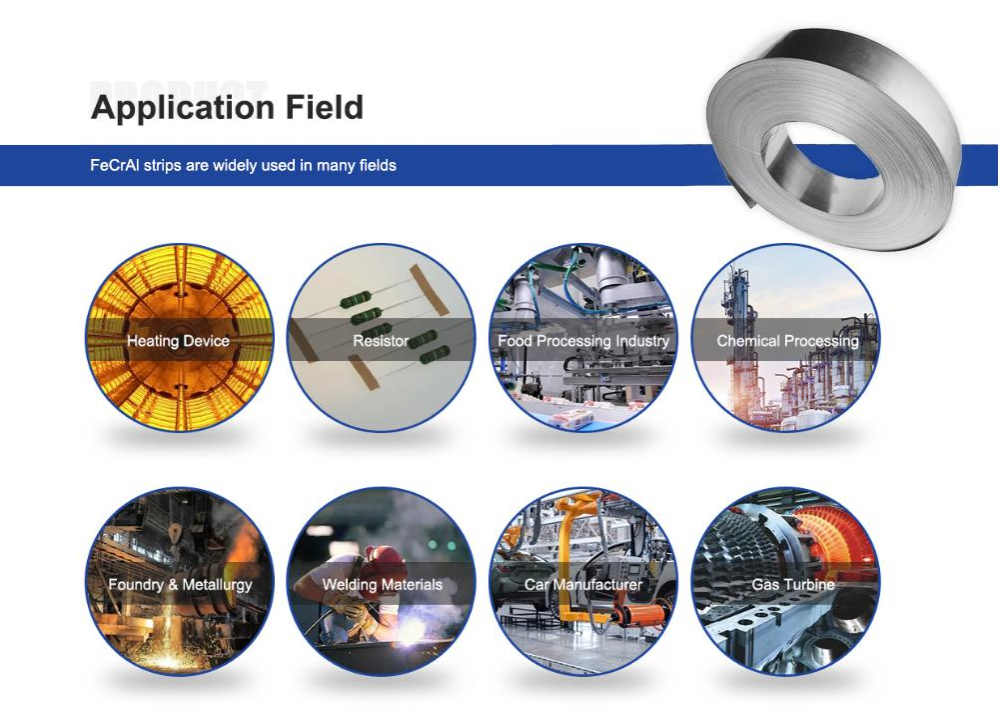

Applications:

One of the most prominent applications of FeCrAl alloy is in the production of heating elements. Thanks to its ferromagnetic properties, this alloy is ideal for use in electric furnaces and other high-temperature heating applications. The high melting point of 1250℃-1500℃ makes it suitable for use in extreme heat environments.

FeCrAl alloy is also widely used in the automotive industry, where it is used for manufacturing exhaust systems. The excellent corrosion resistance of this alloy makes it ideal for use in harsh environments, where exposure to moisture and other corrosive substances can cause damage to other materials.

The excellent weldability of FeCrAl alloy makes it a popular choice for fabricators and manufacturers. It is used in the production of a variety of products, including resistors, electric heating elements, and thermocouples.

DLX FeCrAl alloy is manufactured and sourced from China JiangSu, ensuring high-quality and consistent performance.

In summary, FeCrAl alloy is a highly versatile and reliable material that has found its application in various industries. With its excellent corrosion and oxidation resistance, high melting point, and superior weldability, it is an ideal choice for demanding applications.

Support and Services:

Our FeCrAl Alloy product is backed by our expert technical support team, who can assist with any product-related inquiries, troubleshooting, and recommendations. We also offer a range of services to ensure the best performance and longevity of our product, including:

Custom alloy design and production

Surface treatment and coating options

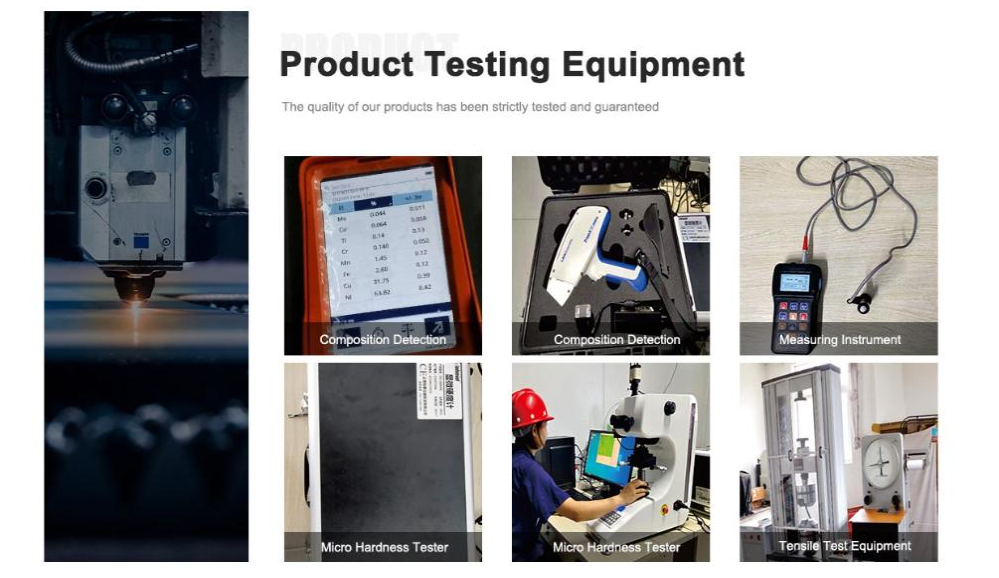

Product testing and analysis

On-site installation and maintenance

Product training and education

Our commitment to customer satisfaction means that we strive to provide comprehensive support and services to meet the needs of our clients.

Packing and Shipping:

Product Packaging:

The FeCrAl Alloy product will be packed securely in a cardboard box to prevent any damage during transit. The product will be wrapped in bubble wrap and sealed with tape to ensure it stays in place during transportation.

Shipping:

Our standard shipping method is via ground transportation. The estimated delivery time is 3-5 business days within the United States. For international orders, delivery times may vary depending on the destination country. We will provide a tracking number once the order has been shipped so you can track the package's progress.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What is FeCrAl alloy?

FeCrAl alloy is an iron-based alloy with 20-30% chromium and 4-6% aluminum, designed for high resistivity, oxidation resistance, and thermal stability up to 1400°C.

What are its key industrial applications?

It’s used in industrial furnaces, kilns, heat treatment systems, appliance heating elements (e.g., toasters, dryers), and electronics due to its heat resistance and efficiency.

How does it perform in high-temperature conditions?

It forms a durable aluminum oxide layer, enabling reliable operation at up to 1400°C, ideal for processes like metal annealing, ceramic firing, or glass production.

How does its resistivity compare to other alloys?

Its resistivity (~1.2-1.5 µΩ·m) is similar to NiCr (~1.0-1.5 µΩ·m) and higher than CuNi44 (~0.49 µΩ·m), making it highly effective for heating elements.

How does it handle corrosive environments?

The aluminum oxide layer provides excellent oxidation resistance, but it’s less effective in sulfur-rich or reducing environments compared to NiCr alloys.

Which industries rely on FeCrAl alloy?

Metallurgy, ceramics, glass, electronics, appliance manufacturing, and aerospace industries use it for heating elements and high-temperature components.

Is it easy to process for manufacturing?

With moderate ductility (15-25% elongation) and weldability, it can be formed into wires, strips, or coils, but its hardness (200-260 HV) requires specialized machining tools.

Why is FeCrAl alloy cost-effective?

Its low nickel content compared to NiCr alloys reduces material costs while maintaining comparable high-temperature performance, ideal for budget-conscious industries.

-

Bright Annealed FeCrAl Alloy with Excellent Oxidation Resistance and Tensile Strength 700MPA

Enquire Now -

Chromium Cast Iron Bar for Corrosion and Oxidation Resistance

Enquire Now -

FeCrAl Alloy Bar with Excellent Corrosion Resistance for Extreme Conditions

Enquire Now -

1250C-1500C Iron Chromium Melting Point chromium aluminum Strip for Superior Resistance and Welding

Enquire Now