What is Electrical Stove Heating element?

Release time:2026-02-25 Strike:1739 Inquire Now

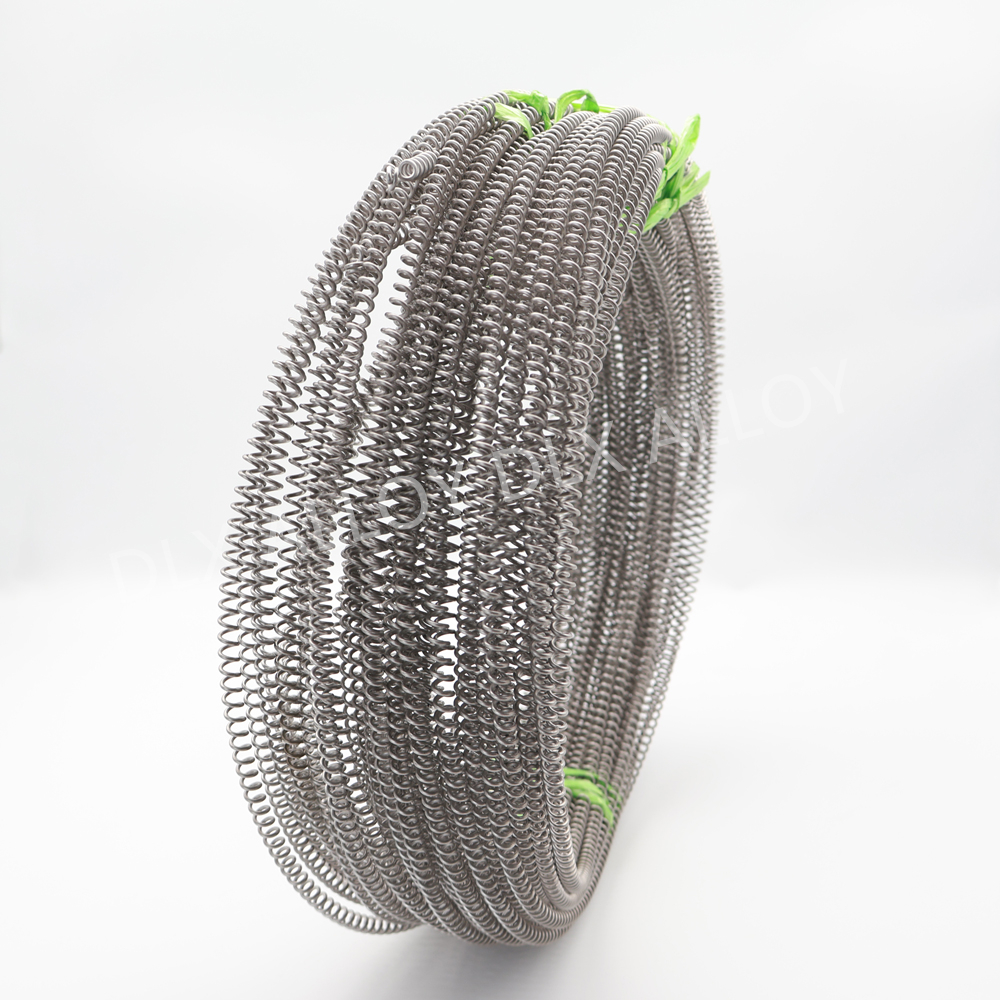

Electric stove heating wires contain small amounts of molybdenum, niobium, cobalt, titanium, and rare earth elements,

primarily used in the manufacture of heat treatment furnaces for quenching, annealing, tempering, and solution treatment, as well as melting furnaces for copper and aluminum alloys.

DLX ALLOY Company produces high-temperature heating wires with high purity, low impurities, stable resistivity, excellent surface oxidation resistance, corrosion resistance,

high-temperature strength, good processing performance, and weldability.

Specifications for electric stove heating wires supplied include wire diameters ranging from Φ0.03 mm to Φ10 mm.

FeCrAl, such as 0Cr27Al7Mo2, 0Cr21Al6Nb, and 0Cr25Al5, is the most widely used material for stove heating elements. The reasons are:

1.FeCrAl can reach temperatures as high as 1400°C.

2. Its High Resistivity enables the stove to be heated in a shorter time.

3. The FeCrAl is economical and durable. Its cost is 5 times less than Nichrome , and its price is relatively stable.

Here is the list of our FeCrAl materials. It will let you know which material could reach the power you need.

Grade Properties | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 1Cr20Al3 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

|---|---|---|---|---|---|---|---|---|

| Chemical | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | Opportune | |

| Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Max Working Temp °C | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resistivity 20ºC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Density (g/cm3) | 7.40 | 7.10 | 7.16 | 7.25 | 7.35 | 7.10 | 7.10 | |

| Thermal Conductivity (KJ/m·h·ºC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| Coe Expansion (α×10-6/ºC) | 15.4 | 16.0 | 14.7 | 15.0 | 13.5 | 16.0 | 16.0 | |

| Melting Point (ºC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

Considerations for electric stove heating wires:

When designing electric stove heating wires, select the correct wire diameter based on a reasonable surface load.

Before installation, thoroughly inspect the furnace, and remove ferrites and carbides to prevent short circuits or wire breakdown.

During installation, connect the wires correctly according to the designed wiring method.

Before use, check the sensitivity of the temperature control system to prevent temperature control failure and subsequent damage to the heating wires.

How to Replace the Heating Elements in the Stove?

1. Place the furnace door facing downwards. (Note: Use bricks to elevate the door off the ground.)

2. Open the rear cover and remove a portion of the insulation cotton, then take out the furnace chamber.

3. Remove all damaged heating wires from inside the furnace chamber. If any heating wires are fused inside, clean the interior thoroughly.

4. Evenly stretch the new heating wires to a length of 6 meters. Then, thread them into the furnace chamber at the original entry and exit points.

5. Place the threaded furnace chamber back into the furnace body. Install insulation cotton, thread insulation beads, connect terminal blocks, secure chimney ceramic pipes, and replace the rear cover.

6. Heating wire replacement is completed.

-

How to Apply for BIS Certificate India

Here is a clear explanation in English on how to apply for a BIS...

-

Alloy28 Stainless steel with 28% Cr and 3% Mo

🔧 UNS N08028 Stainless Steel – Overview and ApplicationsUNS N080...

-

Exploring the Applications of Resistance Wire: From Industrial Heating to Electric Vehicles

Resistance wire is a specialized material widely used in various...

-

How to Caculate the Nichrome80 Temperature

We’re super stoked about our Nichrome 80 wire, a go-to for high-...