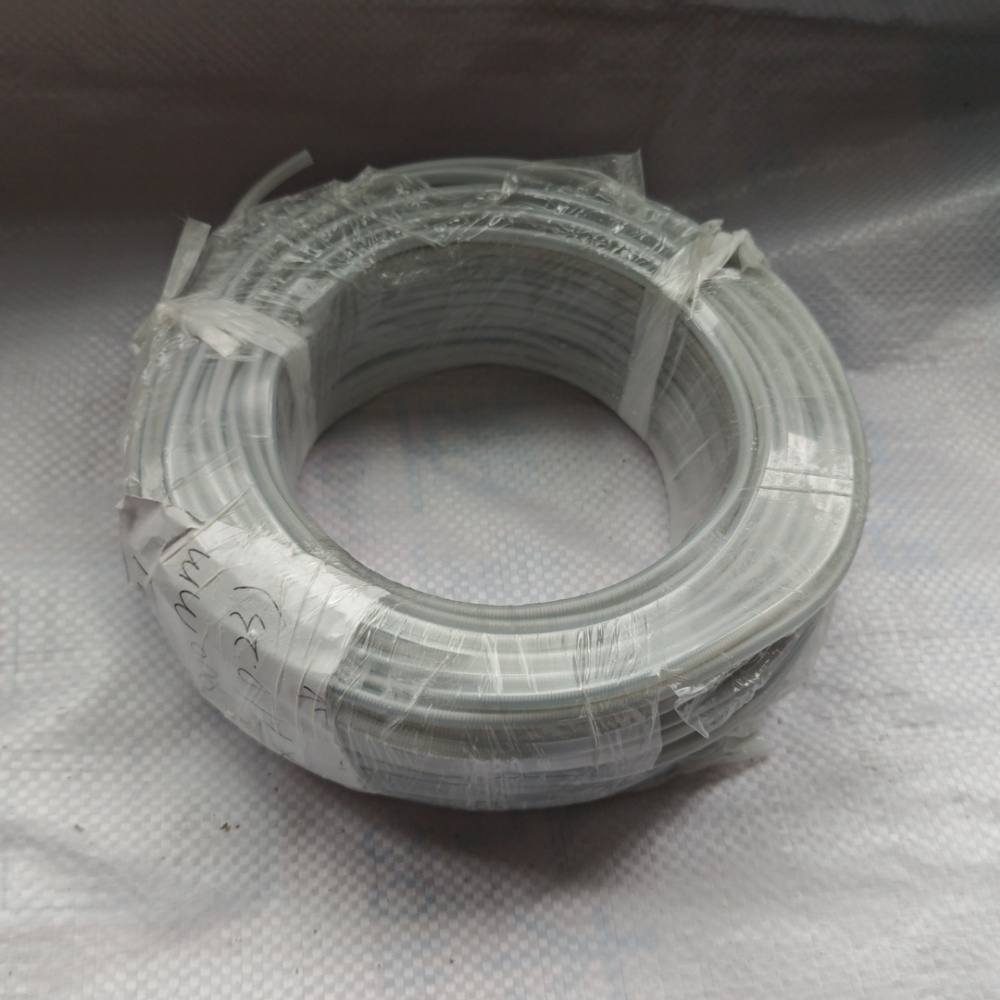

Mini Silicone Heating Cable - Parallel Constant Wattage for Precision Temperature Maintenance

- Product Details

Products Description

What is Mini Silicone Heating Cable?

The Mini Silicone Heating Cable from DLX represents a breakthrough in precision temperature maintenance technology. Designed with a parallel constant wattage system, this advanced heating cable delivers reliable, consistent heat output across its entire length. Encased in a flexible silicone rubber sheath, our heating cable maintains exceptional performance in temperatures ranging from -60°C to +200°C, making it ideal for various industrial and commercial applications where precise temperature control is critical.

The heating cable features a specialized construction with multiple short heating zones connected via continuous bus conductors. This parallel circuit design ensures that even if one section encounters issues, the remainder of the cable continues functioning properly, providing unparalleled reliability for your critical operations. Unlike conventional series heating cables, our parallel constant wattage technology allows the cable to be cut to length from spools and terminated on-site, offering exceptional installation flexibility for projects of any scale.

Why Choose DLX Heating Cable?

DLX's heating solution stands apart from conventional options through its innovative engineering and premium materials. The parallel circuit design provides significant advantages over series circuits, particularly in applications where reliability is paramount. Each heating zone operates independently, creating a robust system that continues functioning even with localized issues.

The silicone rubber construction offers superior temperature maintenance capabilities compared to traditional materials like F46 fluoroplastics . This advanced material maintains flexibility across extreme temperature ranges while providing excellent heat transfer properties. The silicone sheath is resistant to moisture, chemicals, and environmental factors that would degrade lesser materials.

Our heating cable is designed for simplified installation and long-term reliability. The ability to cut the cable to length on-site eliminates the need for custom manufacturing and reduces lead times for urgent projects. The constant wattage output ensures predictable performance that engineers can depend on for critical processes.

Key Features

Precision Temperature Control:

Our parallel constant wattage technology maintains exact temperatures with minimal variance, ensuring your processes remain within optimal parameters.

Exceptional Flexibility:

The high-grade silicone rubber construction allows the cable to be easily wrapped around pipes, vessels, and equipment of various shapes and sizes without compromising performance.

Cut-to-Length Capability:

Unlike fixed-length heating solutions, our heating cable can be customized on-site to meet your exact specifications, reducing waste and installation time.

Rapid Thermal Response:

The advanced heating elements within the silicone construction provide quick heat-up times, responding immediately to temperature changes and control inputs.

Durable Construction:

With a temperature-resistant silicone sheath, our heating cable withstands extreme environments from -60°C to +200°C while maintaining optimal performance.

Parallel Circuit Reliability:

The innovative parallel design ensures continuous operation even if localized damage occurs, providing superior reliability compared to series circuits.

Products Applications

Our Mini Silicone Heating Cable is engineered for diverse applications across multiple industries:

Process Pipe Heating:

Maintain optimal viscosity for fluids in transfer lines, preventing solidification in chemical, petroleum, and food processing applications.

Freeze Protection:

Safeguard water lines, fire suppression systems, and outdoor piping from freezing conditions in commercial and industrial facilities.

Instrument Enclosure Heating:

Prevent condensation and maintain optimal operating temperatures for sensitive electronic equipment and control systems.

Tank and Vessel Heating:

Maintain consistent temperatures in storage tanks, reactors, and processing vessels for optimal material properties.

Roof and Gutter De-icing:

Prevent ice dam formation and gutter freezing in commercial buildings and critical infrastructure.

Food Processing Equipment:

Maintain serving temperatures in hospitality equipment and processing temperatures in food manufacturing applications.

About Us

CHANGZHOU DLX ALLOY CO, LTD was established in 2002. Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy , NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

FAQs:

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.