Cr20Ni30 Resistance Alloy Wire For Thermal Systems

- Product Details

Products Description

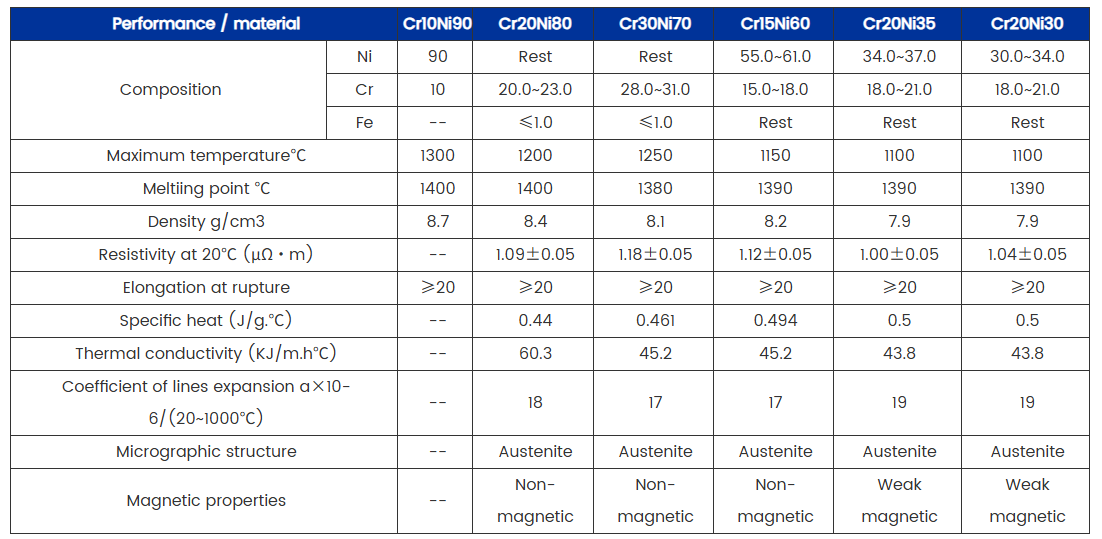

The Cr20Ni30 Resistance Alloy Wire from DLX Alloy is a high-performance material designed for thermal systems operating at temperatures up to 1100°C. Known as a Nichrome-based alloy, Cr20Ni30 Resistance Alloy Wire is composed of 20% chromium and 30% nickel, delivering exceptional oxidation resistance and reliability in demanding industrial environments. This alloy is ideal for applications such as heating elements in industrial furnaces, thermal processing systems, and specialized heating equipment.

With excellent electrical resistivity (approximately 1.04 µΩ·m) and a tensile strength of around 600 MPa, Cr20Ni30 Resistance Alloy Wire ensures consistent performance and durability. Its ability to form a protective oxide layer makes it highly resistant to corrosion, even in challenging conditions with frequent temperature changes. This makes Cr20Ni30 Resistance Alloy Wire a top choice for industries requiring robust and long-lasting thermal solutions.

Products Specification

Key Features

1.High-Temperature Performance

Operates effectively at temperatures up to 1100°C, perfect for thermal systems.

2.Superior Oxidation Resistance

Both alloys form a protective oxide layer, enhancing durability in oxidizing conditions.

3.Consistent Electrical Resistivity

Forms a protective oxide layer, ensuring longevity in oxidizing environments.

4.Durability

High tensile strength ensures long service life, reducing maintenance costs.

5.Formability

Easily shaped into coils, strips, or custom heating elements for tailored industrial solutions.

Why Choose Cr20Ni30 Resistance Alloy Wire?

Compared to other alloys like FeCrAl, Cr20Ni30 Resistance Alloy Wire offers a balanced combination of oxidation resistance, cost-effectiveness, and formability. While FeCrAl alloy s may handle slightly higher temperatures, Cr20Ni30 excels in environments with frequent thermal cycling and oxidizing conditions. Its versatility allows it to be tailored for specific thermal system designs, ensuring optimal performance.

Additionally, Cr20Ni30 Resistance Alloy Wire is engineered to avoid performance issues in reducing atmospheres, provided proper system design is followed. Its durability and low maintenance requirements make it a cost-effective solution for industrial heating needs.

Products Applications

Cr20Ni30 Resistance Alloy Wire is widely used across industries for its reliability and performance in high-temperature environments. Key applications include:

Metal Processing: Powers heat-treating furnaces for annealing, hardening, and tempering metals.

Glass Manufacturing: Provides consistent heating in glass-forming kilns and ovens.

Ceramics Industry: Ensures precise temperature control in ceramic kilns.

Aerospace: Used in specialized heating systems for material testing and component manufacturing.

Domestic and Industrial Appliances: Found in toasters, hair dryers, industrial ovens, and wire-wound resistors.

With the growing demand for energy-efficient and sustainable heating solutions, Cr20Ni30 Resistance Alloy Wire is at the forefront of innovation, meeting the needs of modern industries while reducing environmental impact.

About Us

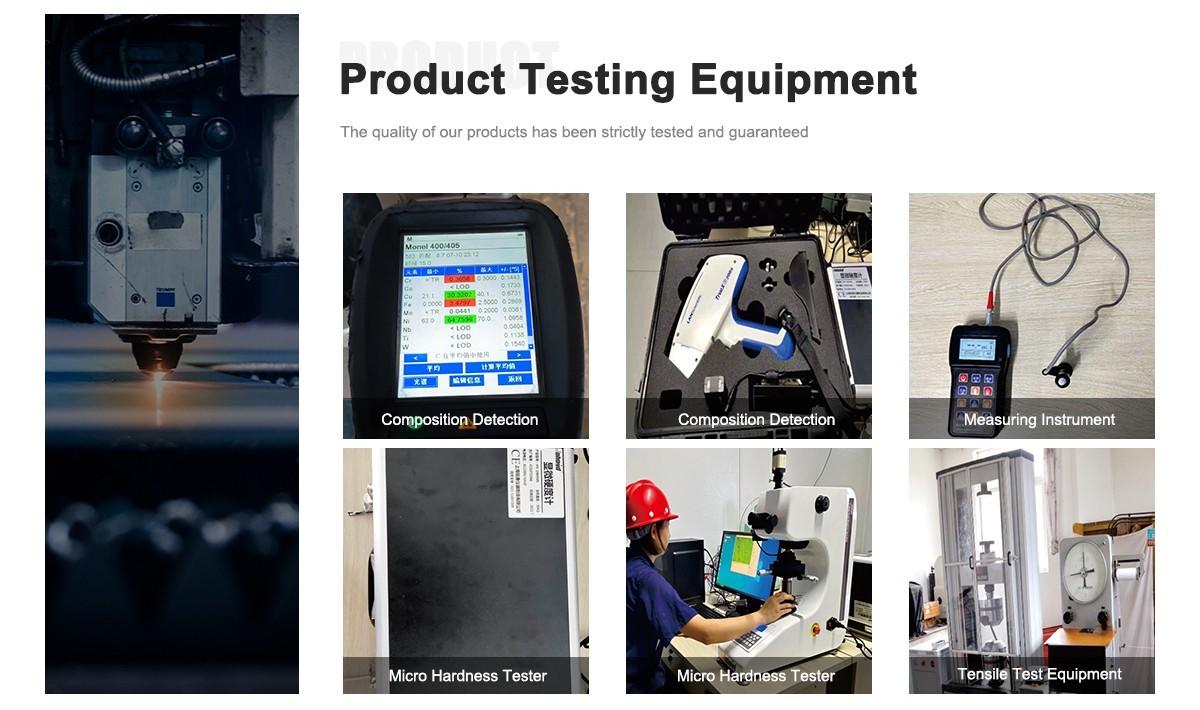

CHANGZHOU DLX ALLOY CO, LTD was established in 2002. Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

FAQs:

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

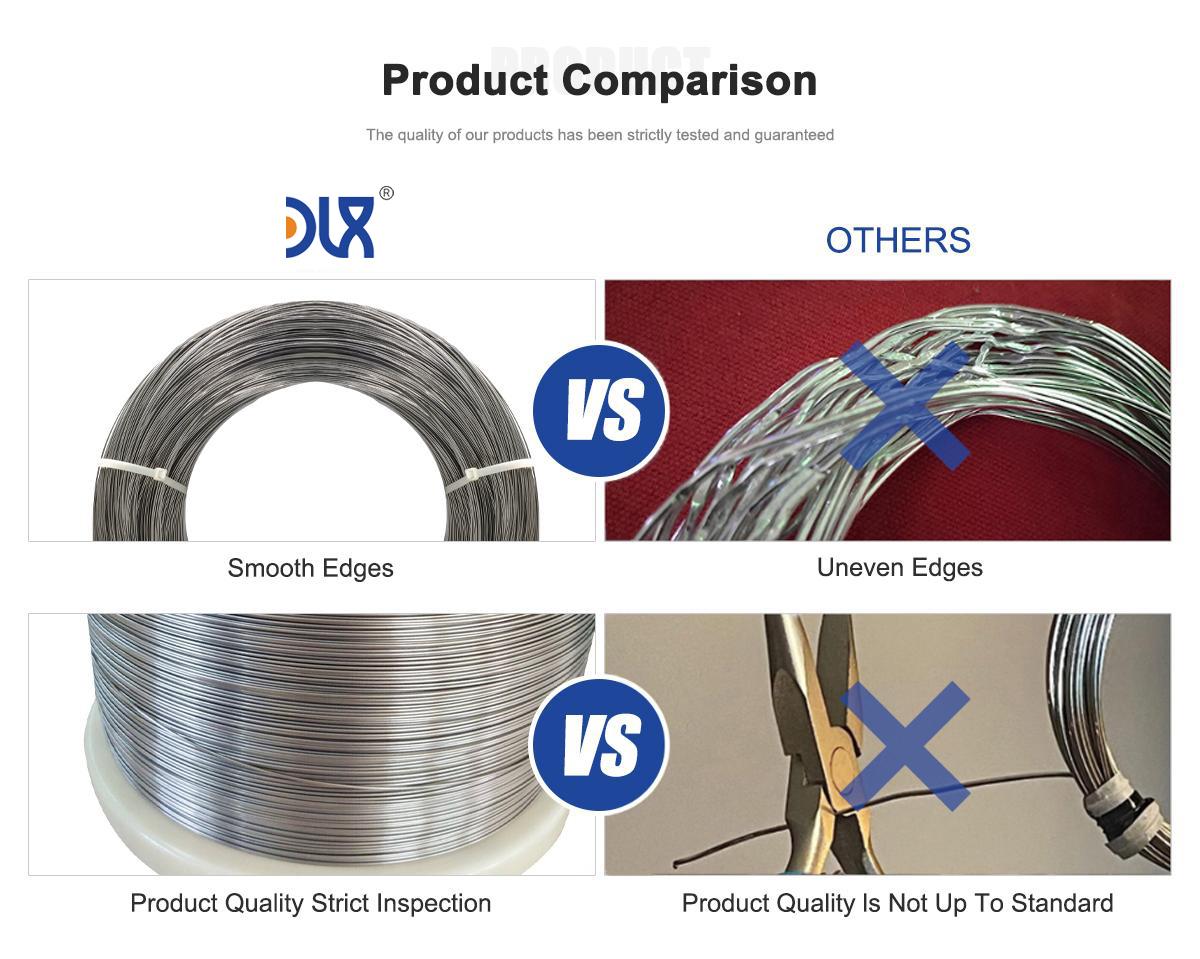

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.

-

Buy Cr20Ni35 NiCr Wire - Optimal for Low Temperature Heating

Enquire Now -

Nichrome 80/20 (Cr20Ni80) Wire Supplier of High-Resistance Heating Alloy

Enquire Now -

Industrial NiCr Heating Wire - Reliable Cr30Ni70 & Cr20Ni35 Alloy

Enquire Now -

High-Temp Nichrome Wire Cr10Ni90 for Heating Elements

Enquire Now