Nichrome Alloy Versatile and Long-Lasting Heating Material for Industries

- Product Details

Nichrome Alloy Versatile and Long-Lasting Heating Material bar for sale

Product Details | |

| Place Of Origin | China |

Brand Name | DLX |

Model Number | Nichrome |

| Payment & Shipping Terms | |

| Minimum Order Quantity | 5 |

| Packaging Details | Spool Package With Carton Box, Coil Package With Polybag |

| Delivery Time | 5-21 Days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

Supply Ability | 300 Tons Per Month |

Product Description:

With a tensile strength of 400-500 MPa, the Nichrome Alloy is highly durable and can withstand high temperatures. Its electrical resistivity of 1.1-1.2 μΩm makes it an excellent conductor of electricity and allows it to generate heat efficiently.

In addition, the Nichrome Alloy has an elongation of 20-30% and a yield strength of 200-300 MPa, which means it can be easily shaped and molded into various forms and sizes without losing its structural integrity.

The Nichrome Alloy is commonly used in the production of nichrome heating elements, which are widely used in various industries such as automotive, aerospace, and chemical. The nichrome heating elements are used for heating liquids, gases, and solids to high temperatures.

Moreover, the Nichrome wire is also used in the manufacturing of electric heating appliances such as toasters, hair dryers, and ovens. This is because of its ability to generate heat quickly and efficiently, which makes it an ideal material for heating applications.

In summary, the Nichrome Alloy is a highly durable and efficient material that is widely used for manufacturing nichrome heating elements, furnaces, and electrical components. Its high tensile strength, electrical resistivity, and elongation make it an excellent conductor of electricity and heat.

Products Features

Features:

Product Name: Nichrome Alloy

Electrical Resistivity: 1.1-1.2 μΩm

Hardness: HV400-500

Density: 8.4 G/cm3

Thermal Conductivity: 15-20 W/mK

Used for Nichrome wire

Can be used for nichrome heating elements

Also known as Nichrome wire

Technical Parameters:

| Melting Point: | 1400-1450°C |

| Thermal Conductivity: | 15-20 W/mK |

| Electrical Resistivity: | 1.1-1.2 μΩm |

| Thermal Expansion: | 13-17 μm/mK |

| Elongation: | 20-30% |

| Corrosion Resistance: | Excellent |

| Forms: | Wire, Sheet, Strip, Rod, Tube |

| Magnetic Properties: | Non-magnetic |

| Tensile Strength: | 400-500 MPa |

| Yield Strength: | 200-300 MPa |

Products Applications

Nichrome wire is a popular choice for heating elements due to its excellent resistance to oxidation and high melting point of 1400-1450°C. It is commonly used in industrial and commercial heating applications such as furnaces, ovens, and kilns. The hardness of HV400-500 and tensile strength of 400-500 MPa makes it durable and able to withstand high temperatures.

Aside from heating elements, Nichrome can also be used in electrical components such as resistors and thermocouples. Its electrical resistivity of 1.1-1.2 μΩm makes it an ideal material for these applications.

DLX Alloy's Nichrome product is available in various forms including wire, sheet, strip, rod, and tube. It comes in spool packages with carton boxes or coil packages with polybags for resistance wire. The minimum order quantity for this product is 5 and the delivery time ranges from 5-21 days depending on the quantity ordered.

Payment terms accepted by DLX Alloy include L/C, T/T, Western Union, and MoneyGram. With a supply ability of 300 tons per month, DLX Alloy can meet the demand for Nichrome in various industries.

Overall, Nichrome is a reliable and durable material that can be used for a wide range of applications. DLX Alloy's Nichrome product offers high-quality and affordable solutions for those in need of heating elements or electrical components.

Support and Services:

Nichrome Alloy is a high-temperature resistant material made of nickel, chromium, and iron. It is commonly used in heating elements, resistors, and other high-temperature applications. Our technical support team is available to assist with any questions or concerns related to the performance or installation of Nichrome Alloy products. Additionally, we offer a range of services including custom fabrication, testing, and certification to ensure the highest quality standards for our customers.

Packing and Shipping:

Product Packaging:

Each Nichrome Alloy product will be carefully wrapped in protective packaging to ensure safe delivery.

The packaging will be sturdy and durable to prevent any damage during shipping.

All necessary labels and markings will be clearly displayed on the packaging.

Shipping:

We offer worldwide shipping for all of our Nichrome Alloy products.

Shipping costs will vary depending on the destination and the weight of the package.

We will provide a tracking number for your shipment so you can monitor its progress.

Delivery times will depend on the shipping method selected and the destination.

About us

About DLX ALLOY

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy , thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

About Our factory

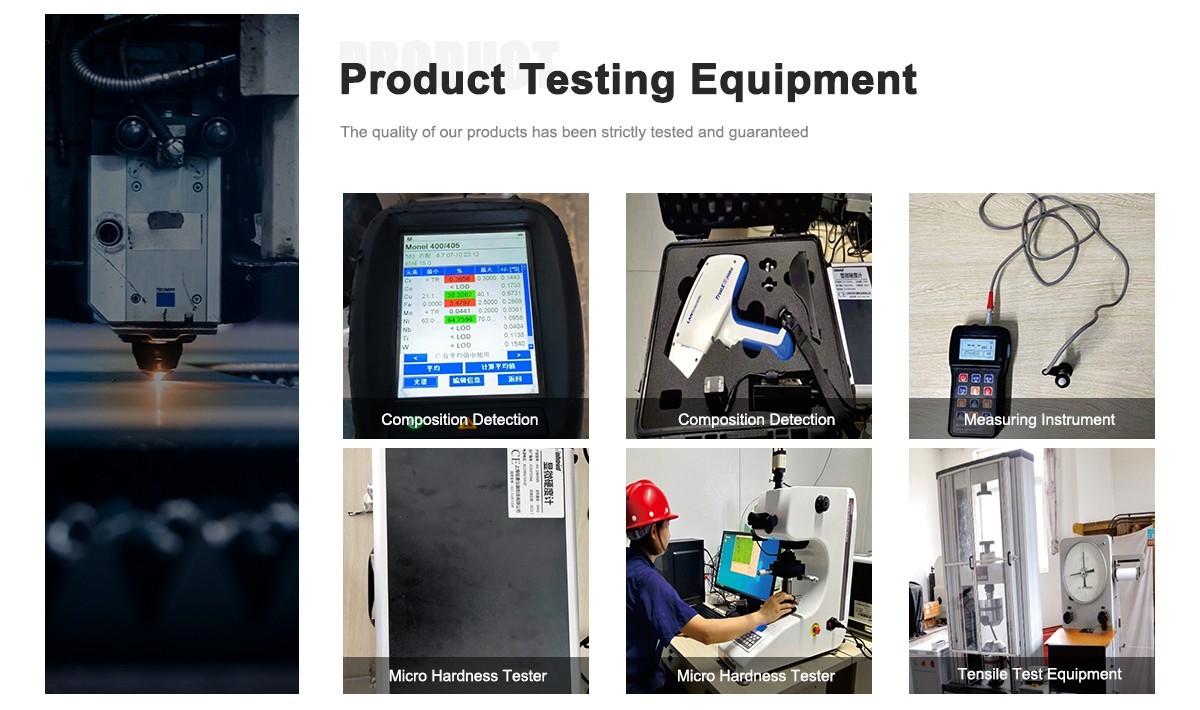

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.