Cr15Ni60 Resistance Heating Strip - Long Lifespan Material

- Product Details

Products Description

What is Cr15Ni60 Resistance Heating Strip?

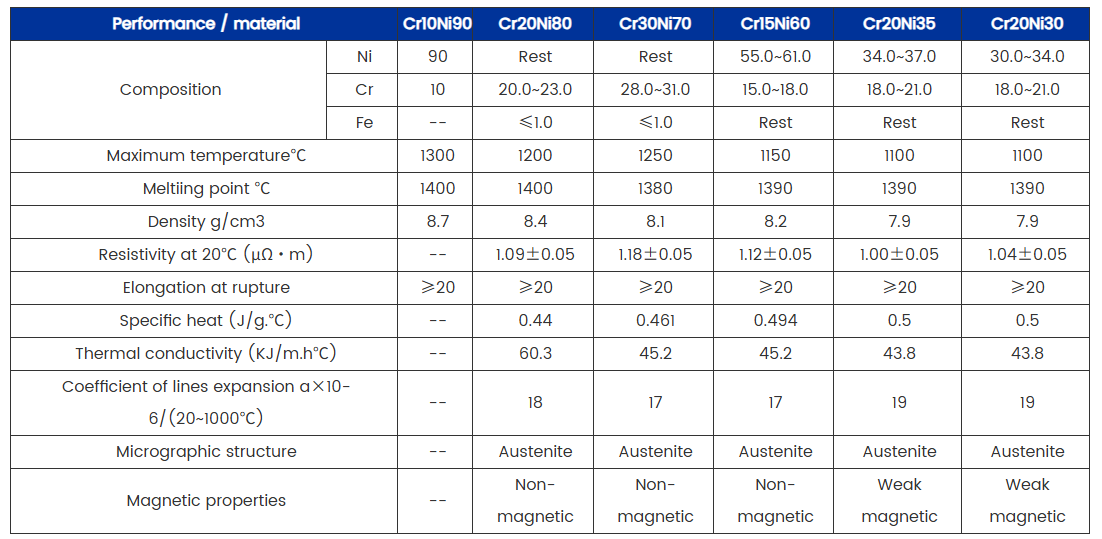

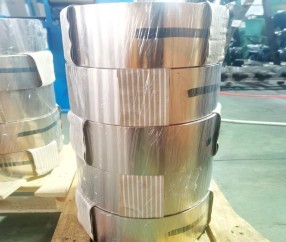

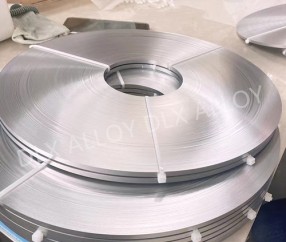

Cr15Ni60 resistance heating strip is a classic nickel-chromium-iron alloy that complies with GB/T 1234 standards for high resistance electric heating alloys. The designation "Cr15Ni60" directly reflects its core alloy composition: approximately 15% chromium and 60% nickel, with the balance being iron and trace elements.

This material is specifically engineered for applications requiring reliable heating elements with extended service life. The alloy maintains excellent high-temperature strength and forms a protective oxide layer that significantly slows down element burnout speed. Available in various strip sizes and dimensions, Cr15Ni60 can be fabricated into different heating element configurations to meet specific application requirements.

The alloy represents an optimal balance between performance and cost-effectiveness, offering better high-temperature capabilities than ordinary resistance heating materials while being more economical than specialized high-temperature alloys. This makes it suitable for both continuous industrial operations and intermittent heating applications.

Products Features

Key Features & Benefits of Our Cr15Ni60 Resistance Heating Strip

Our Nichrome Alloy Strip is designed to meet rigorous industrial standards. Here’s why it's the preferred choice for your industrial heating elements:

Superior High-Temperature Performance: Excellent oxidation resistance, allowing for long service life even at temperatures up to 1200°C.

High Electrical Resistance: The Cr10Ni90 alloy provides high resistivity, which translates to efficient heat generation and lower energy consumption.

Excellent Surface Load Capacity: This Nichrome strip can withstand high surface loads, making it suitable for compact and powerful heating systems.

Good Formability & Weldability: The strip can be easily fabricated, bent, and welded into various shapes for custom heating element designs.

Long-Term Stability: Maintains consistent performance and mechanical strength over prolonged use, reducing downtime and maintenance costs.

Shape | Size(mm) |

| Wire | 0.05-7.5 |

| Rod | 8-50 |

| Ribbon | (0.05-0.35)*(0.5-6.0) |

Strip | (0.5-2.5)*(5-180) |

Products Applications

Applications of Cr15Ni60 Resistance Heating Strip

Cr15Ni60 resistance heating strips are widely used across numerous industries due to their reliable high-temperature performance:

Industrial Electric Furnaces: Commonly employed as heating elements in medium-temperature box furnaces, pit furnaces, and car-bottom furnaces

Home Appliances: Heating elements for electric ovens, hair dryers, irons, electric heaters, and drying equipment

Glass and Ceramic Industries: Heating elements for glass melting electric furnaces and ceramic sintering kilns

Plastics Machinery: Heating rings for injection molding machines, barrel heaters for extruders

Aerospace and Nuclear Industries: Specialized heating devices with specific requirements

Precision Instruments: Resistance elements for high-temperature experimental devices, typically used with insulating ceramics

About us

About DLX ALLOY

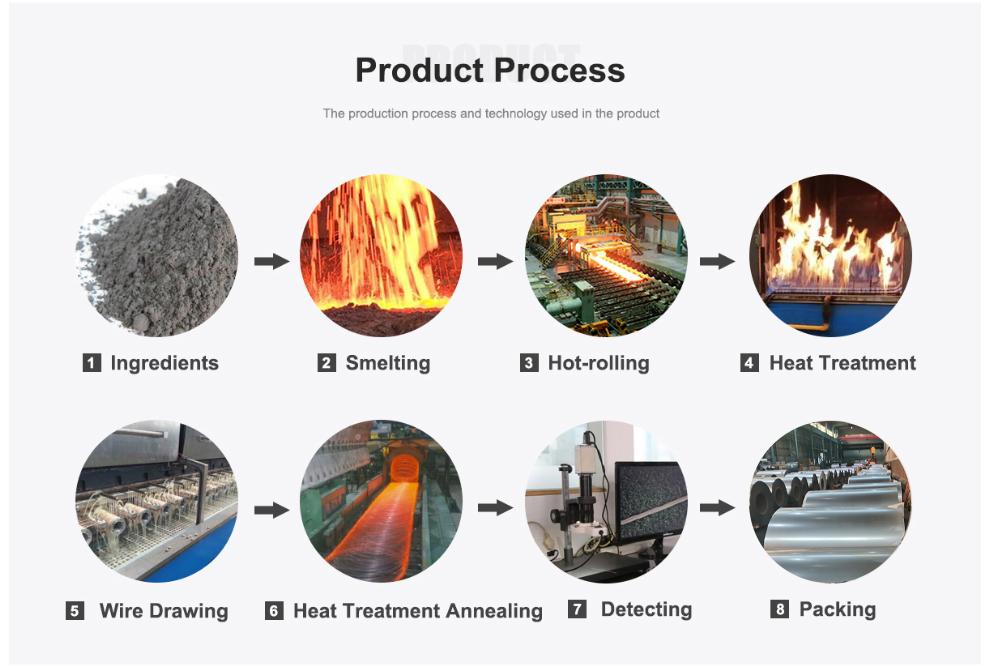

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy , NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

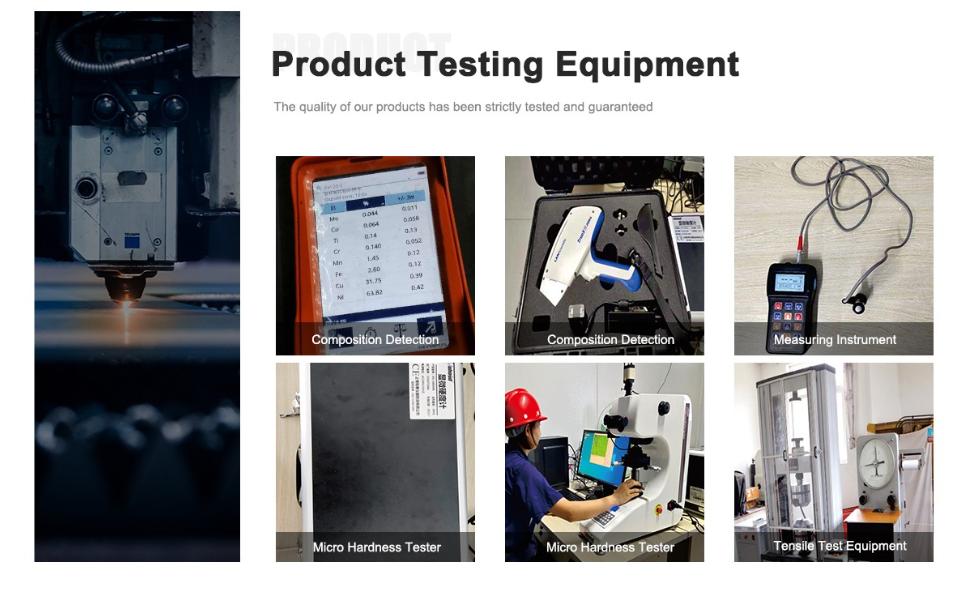

About Our factory

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1: What is Nichrome Strip, and why is it used for heating elements?

Nichrome Strip is a type of nickel chromium alloy specifically designed for high-temperature applications. It is the most common material for heating elements because it combines high electrical resistance with the ability to withstand extreme heat without oxidizing or degrading quickly. This makes Nichrome strip incredibly efficient and durable for the electric heating industry.

2: What are the key benefits of using Cr10Ni90 alloy over other heating alloys?

The Cr10Ni90 alloy offers an excellent balance of properties. It has higher nickel content, which provides superior oxidation resistance and ductility compared to iron-chromium-aluminum (FeCrAl) alloys. This makes the Cr10Ni90 Nichrome strip ideal for applications requiring long life, repeated thermal cycling, and efficient heating in oxidizing atmospheres.

3: Can you customize the Nichrome Alloy Strip to our specifications?

Absolutely. We provide customization for our Nichrome Strip, including specific thicknesses, widths, and tempers to meet the unique requirements of your industrial heating elements. Contact us with your detailed needs.

4. What Are Your Payment Terms for Nichrome Strip?

We accept flexible payment options for Nichrome Strip purchases, including T/T, L/C, D/A, D/P, Western Union, MoneyGram, and PayPal.

5. Can I Visit Your Factory Before Ordering Nichrome Strip?

Absolutely, you're welcome to visit our factory before placing an Nichrome Strip order—we'd love to meet and discuss your requirements.

6. Where Is Your Production Base for Nichrome Strip?

Our Nichrome Strip is manufactured in Jiangsu, China, with fast shipping worldwide based on your order quantity and specifications.

7. Can You Send Nichrome Strip Samples?

Yes, we can provide Nichrome Strip samples to help you evaluate quality before bulk ordering.

-

Cost-Effective NiCr Conductive Strip - Reliable Performance for OEMs

Enquire Now -

NiCr Conductive Strip Material - Good Weldability & Stability for Hydrogen Equipment

Enquire Now -

Advanced NiCr Strip for Next-Gen High-Pressure Electrolyzers

Enquire Now -

Corrosion Resistant NiCr Strip - Ideal for Alkaline Water Electrolysis Systems

Enquire Now