Durable NiCr Conductive Strip Solution for Industrial Water Electrolysis

- Product Details

Products Description

What is NiCr Conductive Strip?

Our NiCr Conductive Strip is a premium Nickel-Chromium (NiCr) alloy strip specifically engineered for demanding applications in the hydrogen energy sector, particularly in industrial water electrolysis systems. As a critical component within electrolyzer stacks, this NiCr Conductive Strip ensures efficient and reliable transfer of electrical current under high-temperature and corrosive operating conditions. Manufactured with precision, our NiCr strip is the material of choice for OEMs seeking to enhance the performance, durability, and longevity of their hydrogen production equipment.

The alloy represents an optimal balance between performance and cost-effectiveness, offering better high-temperature capabilities than ordinary resistance heating materials while being more economical than specialized high-temperature alloys. This makes it suitable for both continuous industrial operations and intermittent heating applications.

Products Features

Key Features & Benefits of Our NiCr Conductive Strip

The superior performance of our NiCr Conductive Strip in water electrolysis applications is defined by a set of key characteristics:

Excellent Oxidation Resistance: The high chromium content forms a protective oxide layer, enabling the NiCr strip to withstand high-temperature oxidizing atmospheres inside electrolyzers, preventing rapid degradation.

High-Temperature Strength: Maintains excellent mechanical integrity and resists sagging or creep even at the elevated temperatures common in industrial water electrolysis processes.

Superior Electrical Conductivity: Provides stable and low-resistance electrical pathways, which is crucial for maximizing the energy efficiency of the hydrogen production process.

Long-Term Durability: Designed for a long service life, this NiCr Conductive Strip reduces maintenance downtime and replacement costs, contributing to a lower total cost of ownership for your hydrogen energy systems.

Good Corrosion Resistance: Resists attack from the electrolyte environment, ensuring consistent performance and structural reliability.

Consistent Material Properties: Our strict quality control guarantees uniform composition and properties across every batch of NiCr strip, ensuring predictable performance in your designs.

Shape | Size(mm) |

| Wire | 0.05-7.5 |

| Rod | 8-50 |

| Ribbon | (0.05-0.35)*(0.5-6.0) |

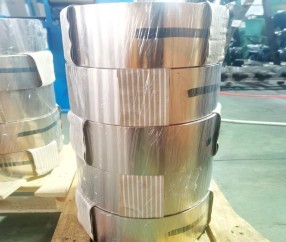

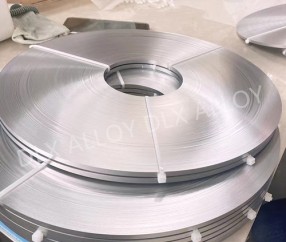

Strip | (0.5-2.5)*(5-180) |

Products Applications

Applications of NiCr Conductive Strip

This NiCr Conductive Strip is primarily used in the hydrogen energy sector, specifically in electrolytic hydrogen production systems.

PEM Water Electrolyzer Stacks:

Used as a key material for bipolar plates and current collectors, where it distributes electrical current and separates individual cells.

Anode Side Components:

Its superior corrosion resistance makes it ideal for components exposed to the harsh anodic environment of oxygen evolution.

Green Hydrogen Production Equipment:

An essential material in the manufacturing of stacks for high-pressure and high-efficiency PEM electrolyzers.

Fuel Cells & Other Energy Conversion Devices:

The properties of the NiCr strip are also beneficial in related technologies requiring corrosion-resistant conductive materials.

About us

About DLX ALLOY

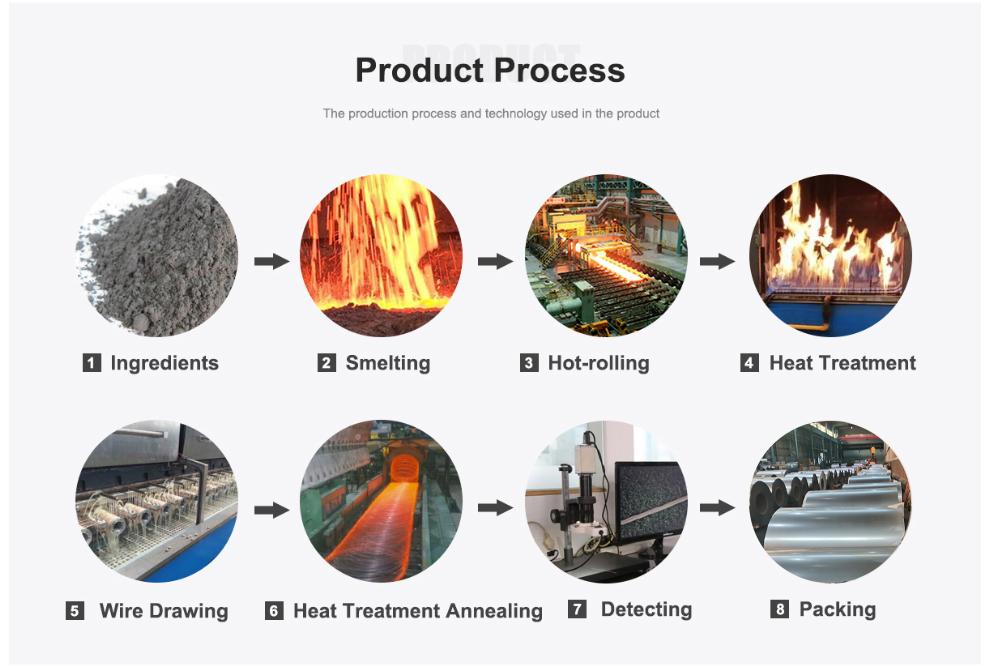

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy , NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

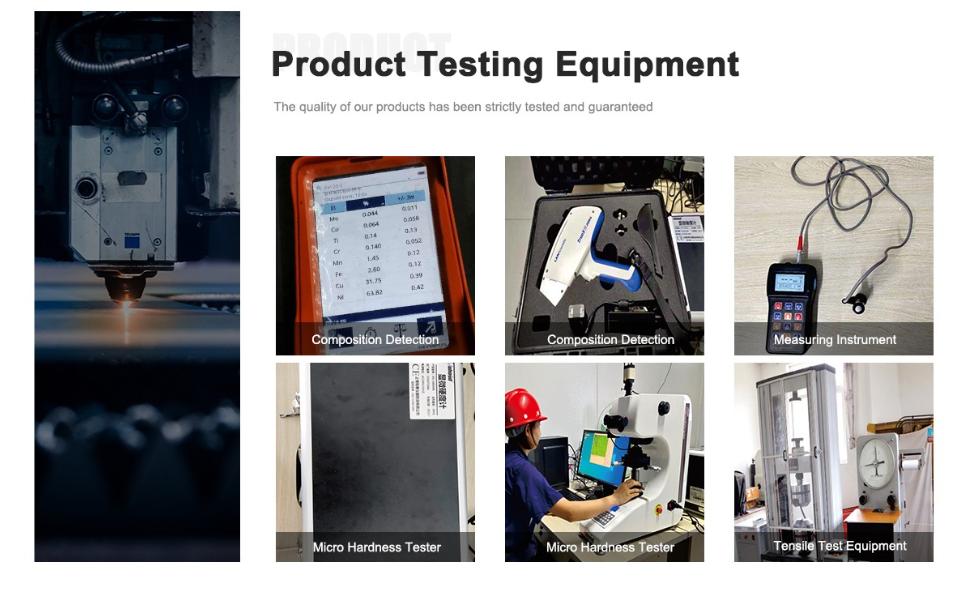

About Our factory

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1: What is a NiCr conductive strip used for in hydrogen production?

The NiCr conductive strip is a critical material used within PEM water electrolyzers. It functions primarily as a bipolar plate or current collector, responsible for distributing electrical current evenly across the membrane electrode assembly and providing structural support within the electrolyzer stack, all while resisting severe corrosion.

2: Why is corrosion resistance so important for the NiCr strip in a PEM electrolyzer?

On the anode side of a PEM electrolyzer, the material is exposed to highly acidic conditions, high electrical potentials, and oxygen. Standard materials would corrode quickly, leading to contamination and failure. Our NiCr conductive strip's excellent corrosion resistance ensures long-term stability and prevents performance degradation.

3: Can you customize the Nichrome Alloy Strip to our specifications?

Absolutely. We provide customization for our Nichrome Strip, including specific thicknesses, widths, and tempers to meet the unique requirements of your industrial heating elements. Contact us with your detailed needs.

4. What Are Your Payment Terms for Nichrome Strip?

We accept flexible payment options for Nichrome Strip purchases, including T/T, L/C, D/A, D/P, Western Union, MoneyGram, and PayPal.

5. Can I Visit Your Factory Before Ordering Nichrome Strip?

Absolutely, you're welcome to visit our factory before placing an Nichrome Strip order—we'd love to meet and discuss your requirements.

6. Where Is Your Production Base for Nichrome Strip?

Our Nichrome Strip is manufactured in Jiangsu, China, with fast shipping worldwide based on your order quantity and specifications.

7. Can You Send Nichrome Strip Samples?

Yes, we can provide Nichrome Strip samples to help you evaluate quality before bulk ordering.

-

Cost-Effective NiCr Conductive Strip - Reliable Performance for OEMs

Enquire Now -

NiCr Conductive Strip Material - Good Weldability & Stability for Hydrogen Equipment

Enquire Now -

Advanced NiCr Strip for Next-Gen High-Pressure Electrolyzers

Enquire Now -

Corrosion Resistant NiCr Strip - Ideal for Alkaline Water Electrolysis Systems

Enquire Now