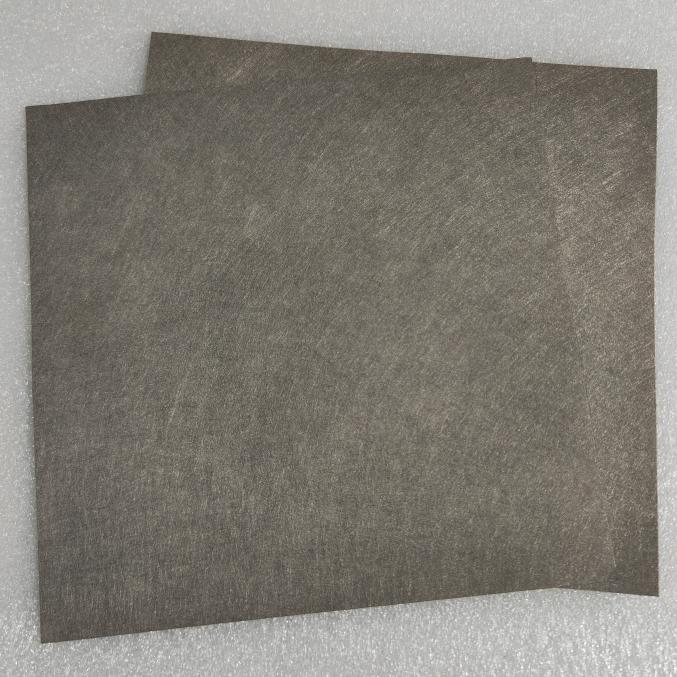

Titanium Fiber Felt: Lightweight, Corrosion-Resistant Porous Metal Media

- Product Details

Titanium Fiber Felt: Lightweight, Corrosion-Resistant Porous Metal Media

Titanium fiber felt is a nonwoven porous material made from pure titanium fibers through a process of needle-punching and high-temperature sintering. Known for its exceptional corrosion resistance, biocompatibility, and structural integrity, titanium fiber felt is widely used in advanced filtration, energy systems, and biomedical devices.

Key Features

Excellent Corrosion Resistance: Titanium naturally forms a stable oxide layer, offering outstanding resistance to acids, alkalis, and seawater environments.

High Porosity and Surface Area: Typically 70%–90% porosity, ideal for filtration, electrode scaffolding, and gas diffusion applications.

Mechanical Strength & Formability: Maintains structural integrity under pressure; can be rolled, welded, or shaped without cracking.

High-Temperature Stability: Operational up to 500–600°C in inert or mildly oxidative environments.

Biocompatibility: Non-toxic and suitable for medical implantables, such as bone scaffolds or tissue engineering.

Typical Applications

Electrodes for PEM Electrolyzers & Fuel Cells: As a gas diffusion layer (GDL) or porous transport layer (PTL) for proton exchange membrane (PEM) water electrolysis and hydrogen fuel cells.

Battery Current Collectors: Used in solid-state and lithium-metal battery architectures.

Biomedical Implants: Structural support in dental and orthopedic implants, tissue scaffolds.

Precision Filtration: Fine filtration of aggressive chemical or high-purity fluid systems.

Heat Exchangers: Lightweight, corrosion-resistant alternatives to metal foams.

Technical Specifications (Typical Ranges)

| Property | Value |

|---|---|

| Material | ≥99.6% Pure Titanium |

| Fiber Diameter | 10–40 microns |

| Thickness | 0.2mm – 5mm |

| Porosity | 70–90% |

| Surface Density | 200–1000 g/m² |

| Operating Temp | ≤600°C |

Why Choose Titanium Fiber Felt?

Titanium fiber felt delivers an ideal combination of lightweight design, chemical stability, and electrical conductivity, making it a strategic material for next-generation energy systems and medical technologies. It is available in rolls, sheets, or custom-cut forms for integration into various industrial designs.