0.1-10mm Cu/Ni Alloy Rod 8.94 G/cm3 Density 0.12\u03bc\u03a9.m20\u00b0C Resistivity

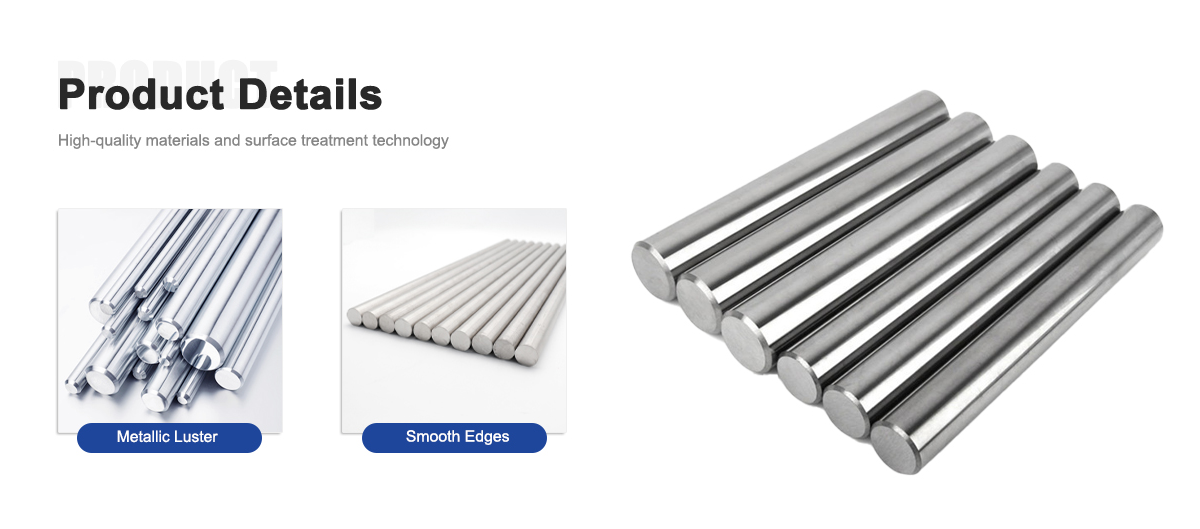

- Product Details

We’re pumped to roll out our 0.1-10mm Cu/Ni alloy rods, packing a density of 8.94 g/cm³ and a resistivity of 0.12 μΩ·m at 20°C. These rods, with around 23% nickel, are high-performance workhorses built for businesses that need reliability and versatility. Let’s break down why these rods are such a hot ticket.

This Cu/Ni alloy is a go-to for a ton of applications. Its stable resistivity makes it perfect for heating elements in industrial systems or electrical connectors in automotive setups. Got marine projects? These rods laugh off seawater corrosion, making them ideal for fittings and piping. With a density of 8.94 g/cm³, they’re consistent and durable, and their high ductility means you can shape or machine them into whatever you need. From 0.1mm wires to 10mm rods, they’re ready to roll for jobs big and small.

The industry’s on fire, and we’re right in the mix. Copper-nickel alloys are growing at a 5-7% clip each year, fueled by electric vehicles, renewable energy, and marine tech. You’ll find our rods in everything from EV battery components to offshore platform gear. We’re shipping to over 50 countries, with ISO:9001 certification ensuring every rod’s top-notch. Plus, these rods are 100% recyclable, meeting RoHS standards, which our eco-minded clients love.

What makes our Cu/Ni rods stand out is their flexibility. That 0.12 μΩ·m resistivity hits a sweet spot for mid-range heating and resistive applications, and we can customize sizes or forms to fit your project. The bright finish isn’t just pretty—it ensures smooth fabrication. Our R&D crew’s always tweaking things, boosting conductivity or durability for cutting-edge uses like smart electronics or green energy systems.

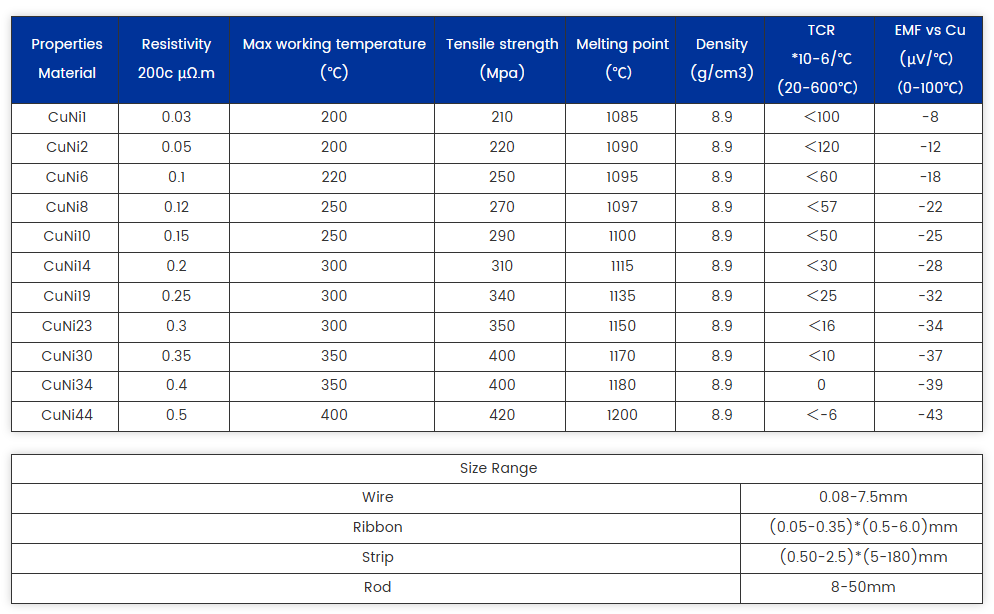

This alloy’s not the answer for every job. If you need ultra-high heat resistance, CuNi 44’s better. On a tight budget? CuNi10 might be your pick. But with its 23% nickel, 8.94 g/cm³ density, and solid performance up to 400°C, this alloy’s a versatile champ for precision and durability. Its non-magnetic vibe and corrosion resistance make it a favorite for tough environments.

Our 0.1-10mm Cu/Ni alloy rods are more than just metal—they’re custom solutions for businesses pushing the envelope. We’re stoked to craft these rods and help our clients power up their projects, from the shop floor to the high seas.

Specification

For more details, pls directly contact us.

Product Description:

Our CuNi Alloy is available in a diameter range of 0.1~10mm, making it suitable for a wide variety of applications. Whether you need it for electrical wiring, heat exchangers, or marine equipment, this Copper Alloy Rod has got you covered.

Thanks to its excellent thermal and electrical conductivity properties, CuNi Alloy is a popular choice for various industrial applications. Its high resistance to corrosion also makes it ideal for use in marine environments.

So if you're looking for a reliable and long-lasting Copper Metal Product, consider our CuNi Alloy. With its high-quality materials and exceptional performance, this Copper Alloy Rod is sure to exceed your expectations. Contact us today to place your order!

Applications:

Marine: The DLX CuNi Alloy is widely used in the marine industry due to its excellent corrosion resistance and high strength. It is commonly used for the production of propeller shafts, seawater cooling systems, and other marine equipment that requires high durability and resistance to saltwater corrosion.

Oil & Gas: The CuNi Alloy product is also suitable for use in the oil and gas industry. It can withstand high temperatures and pressures, making it ideal for use in pipelines, heat exchangers, and other equipment used in oil and gas processing. The product's resistance to corrosion also makes it useful in offshore drilling applications.

Power Generation: The DLX CuNi Alloy is ideal for use in power generation equipment due to its high heat resistance. It can withstand temperatures of up to 350℃, making it ideal for use in power plants and other high-temperature applications. The product is commonly used to produce heat exchangers, steam generators, and turbines.

Chemical Processing: The CuNi Alloy product is also used in the chemical processing industry due to its excellent corrosion resistance. It is commonly used to produce chemical equipment, such as reactors, distillation columns, and heat exchangers, that require resistance to aggressive chemicals and high temperatures.

The DLX CuNi Alloy product is an Aluminium Copper Alloy, which has a melting point of 1280-1330 °C and a diameter range of 0.1~10mm. It has a density of 8.94 G/cm3, making it a lightweight yet durable material. Its excellent properties make it a versatile material that can be used in various applications in different industries.

Support and Services:

Our CuNi alloy product is backed by our technical support and services team who are dedicated to providing our customers with the best possible experience. Our team is available to answer any technical questions or concerns you may have regarding the product's performance, installation, and maintenance. We also offer a range of services including product customization, testing, and quality control to ensure that our customers receive a high-quality product that meets their specific needs. Contact us today to learn more about our technical support and services for CuNi alloy.

Packing and Shipping:

Product Packaging:

Our CuNi Alloy products are carefully packaged to ensure their safety during transportation. The products are wrapped in protective materials and placed in sturdy boxes or crates to prevent any damage. We also label each package with the product name, quantity, and any other necessary information for easy identification.

Shipping:

We offer various shipping options to meet our customers' needs. Our standard shipping method is by sea, but we can also arrange for air freight if necessary. We work with reliable shipping companies to ensure timely and safe delivery of our CuNi Alloy products. Customers can track their shipment through our website or by contacting our customer service department.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What’s this Cu/Ni alloy rod used for?

It’s ideal for heating elements, electrical connectors, and marine fittings.

How corrosion-resistant is this alloy?

It’s super tough, especially against seawater and industrial chemicals.

What’s the max temperature it can handle?

It’s good up to around 350°C, depending on the application.

Is this alloy magnetic?

No, it’s non-magnetic, perfect for electronics and sensors.

Can these rods be welded or soldered?

Yep, they weld and solder easily for flexible fabrication.

Which industries use these rods?

Marine, automotive, electronics, and renewable energy are the main ones.

How does this alloy compare to other Cu/Ni alloys?

Its 0.12 μΩ·m resistivity and 8.94 g/cm³ density make it a mid-range performer, stronger than CuNi2 but less costly than CuNi44.

Is this alloy eco-friendly?

It’s fully recyclable and meets standards like RoHS.

-

Wholesale Price Copper Nickel Alloy CuNi8 CuNi 10 Round Rod Bar

Enquire Now -

Good Price Nickel Alloy CuNi8 CuNi10 Round & Square Bar For Sale

Enquire Now -

CuNi2 Bar CuNi Alloy Various CuNi Models CuNi2 CuNi6 Bar/ CuNi44 Rod

Enquire Now -

High Quality Customized CuNi Super Alloy Factory Direct Supply Super Bar CuNi8

Enquire Now