400 MPa Tensile Strength Alloy Steel Metal Copper Nickel Alloy Bar

- Product Details

We’re pumped to roll out our 400 MPa tensile strength CuNi alloy bars, a perfect blend of toughness and versatility for high-performance industrial applications. With options like CuNi10, CuNi30, and CuNi44, these bars are built to handle serious demands while staying easy to work with. Let’s dive into why these bars are a game-changer for your business.

Our CuNi bars are designed to tackle a wide range of tough jobs. CuNi10’s a solid, cost-effective choice for marine fittings or heating cables, shrugging off corrosion like a champ. CuNi30, with its 400 MPa strength, steps it up for structural components or heating elements that need extra durability in harsh environments. And CuNi44? It’s the go-to for high-heat precision, like thermocouples in aerospace or resistors in cutting-edge electronics, handling temps up to 600°C. All our bars are non-magnetic, super formable, and easy to weld, making them a breeze to shape for any project.

The industry’s buzzing, and we’re right in the mix. Copper-nickel alloys are growing at a 5-7% clip annually, driven by demand in marine, automotive, aerospace, and renewable energy sectors. Our bars are popping up in everything from offshore platform fittings to EV battery components. We’re shipping to over 60 countries, backed by ISO:9001 certification, ensuring every bar’s top-notch. Plus, they’re 100% recyclable, meeting RoHS standards, which our eco-conscious clients love.

What makes our CuNi bars stand out is how customizable they are. From 0.1mm wires to 50mm bars, we can tweak sizes or forms to fit your exact needs. The bright, annealed finish ensures smooth machining, and our R&D team’s always pushing the limits, fine-tuning alloys for better strength or conductivity in next-gen applications like smart electronics or renewable energy systems.

Each alloy’s got its own vibe. CuNi10’s great for balancing cost and performance. CuNi30’s your pick for high-strength, mid-to-high temp jobs. CuNi44’s the premium choice for extreme heat and precision but comes at a higher cost. Whatever your project, we’ve got the know-how to deliver the right bar with that 400 MPa strength to keep things solid.

Our CuNi alloy bars aren’t just metal—they’re high-performance, durable solutions that elevate your products. We’re stoked to craft these bars and help you power up your business, from rugged industrial setups to the cutting edge of tech.

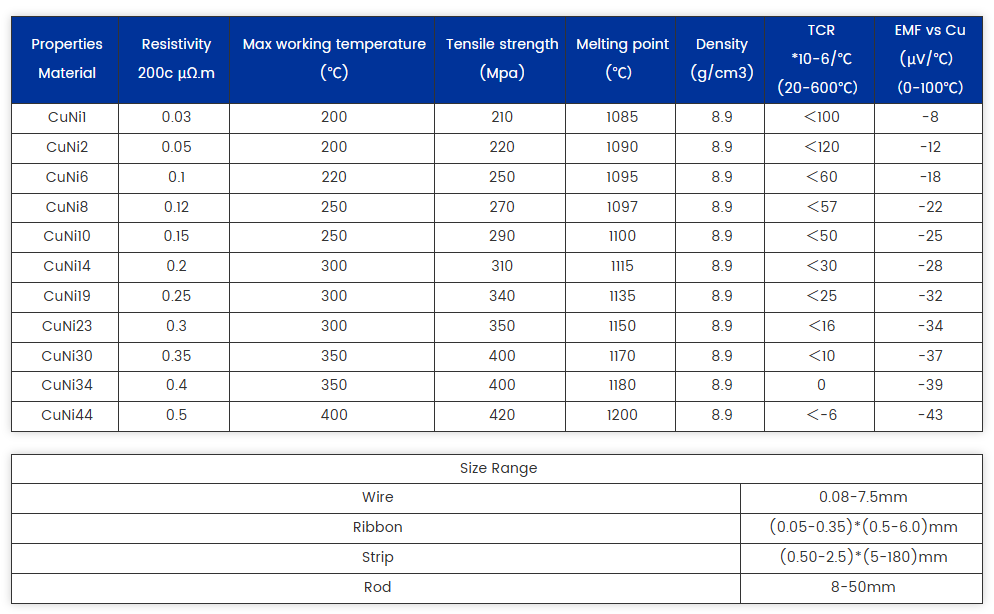

Specification

For more details, pls directly contact us.

Product Description:

Our Copper Nickel Alloy is available in a range of sizes, including a diameter range of 0.1~10mm. This allows for greater flexibility in designing and implementing a wide range of applications. Our Copper Nickel Alloy is perfect for a variety of applications, including Copper Alloy Tube manufacturing, electronics, marine, and automotive industries, and many more.

One of the key features of our Copper Nickel Alloy product is its superior thermal expansion coefficient of 16.5 X 10^-6/K. This makes it an ideal choice for applications that require high-temperature stability, such as those found in the automotive and electronics industries.

In addition, our Copper Nickel Alloy product boasts an impressive hardness range of 80-120 HV, which makes it highly resistant to wear and tear. This makes it an ideal choice for applications that require a high level of durability, such as those found in the marine and aerospace industries.

Our Copper Nickel Alloy product also has a high tensile strength of 400-600 MPa, which makes it an ideal choice for applications that require high strength and reliability. This makes it an ideal choice for applications that require a high level of performance, such as those found in the automotive and aerospace industries.

Finally, our Copper Nickel Alloy product has a density of 8.94 G/cm3, which makes it an ideal choice for applications that require a lightweight yet durable material. This makes it an ideal choice for applications that require a high level of performance while keeping weight to a minimum.

Overall, our Copper Nickel Alloy product is a top-quality alloy that offers superior performance and durability for a wide range of applications. Whether you are looking for a Copper Alloy Tube or need a high-performance material for your electronics or automotive project, our Copper Nickel Alloy product is the perfect choice.

Features:

Product Name: CuNi Alloy

Resistivity: 0.5

Corrosion Resistance: Excellent

Hardness: 80-120 HV

Maximum Temperature: 200℃

Surface: Bright

Material Type: Inconel Nickel Alloy, Aluminium Copper Alloy, Copper Alloy Tube

Applications:

Copper metal products are widely used in industries such as aerospace, automotive, electronics, and construction due to their excellent properties. The DLX CuNi Alloy product is a type of copper based alloy that has excellent corrosion resistance and high thermal conductivity. Due to its high purity, this product is suitable for use in various applications that require high performance and durability.

The DLX CuNi Alloy product is commonly used in the electronics industry to manufacture electrical connectors, relays, and switches. Its excellent conductivity and corrosion resistance make it an ideal material for these applications. In the automotive industry, this product is used to manufacture spark plug electrodes, fuel injectors, and other engine components. Its high thermal conductivity and corrosion resistance make it suitable for use in the harsh environment of an engine.

The DLX CuNi Alloy product is also used in the construction industry to manufacture heating, ventilation, and air conditioning (HVAC) systems. Its excellent thermal conductivity and corrosion resistance make it an ideal material for these applications. It is also used in the aerospace industry to manufacture aircraft components such as heat exchangers and hydraulic tubing.

In conclusion, the DLX CuNi Alloy product is a type of copper based alloy that has excellent properties and is widely used in various industries. Its high thermal conductivity, corrosion resistance, and high purity make it an ideal material for applications that require high performance and durability.

Customization:

Brand Name: DLX

Model Number: CuNi Alloy

Place of Origin: China

Thermal Expansion Coefficient: 16.5 X 10^-6/K

Purity: High Purity

Condition: Hard / Soft

Application: Industry

Emf Vs Cu: -18 UV/C

Our CuNi Alloy is an Inconel Nickel Alloy that is highly resistant to corrosion and oxidation. It is a durable Alloy Steel Metal that is perfect for use in a variety of industrial applications. Contact us today to customize your order.

Support and Services:

Our CuNi alloy product comes with comprehensive technical support and services to ensure the best possible performance and longevity of the product. Our team of experts is available to assist with any product-related queries and concerns, including:

Recommendations for optimal usage and maintenance

Technical troubleshooting and problem-solving

Product customization and special requests

Warranty support and claims

Product training and education

We are committed to providing exceptional customer support and ensuring that our CuNi alloy product meets your exact requirements.

Packing and Shipping:

Product Name: CuNi Alloy

Quantity: 1kg

Dimensions: 10cm x 10cm x 10cm

Weight: 1.5kg

Material: Copper Nickel Alloy

Country of Origin: USA

Packaging: The CuNi Alloy product will be packed in a sturdy cardboard box with proper cushioning to prevent any damage during transit.

Shipping: The product will be shipped via FedEx Ground and the estimated delivery time is 3-5 business days within the USA. International shipping options are also available upon request.

About Us:

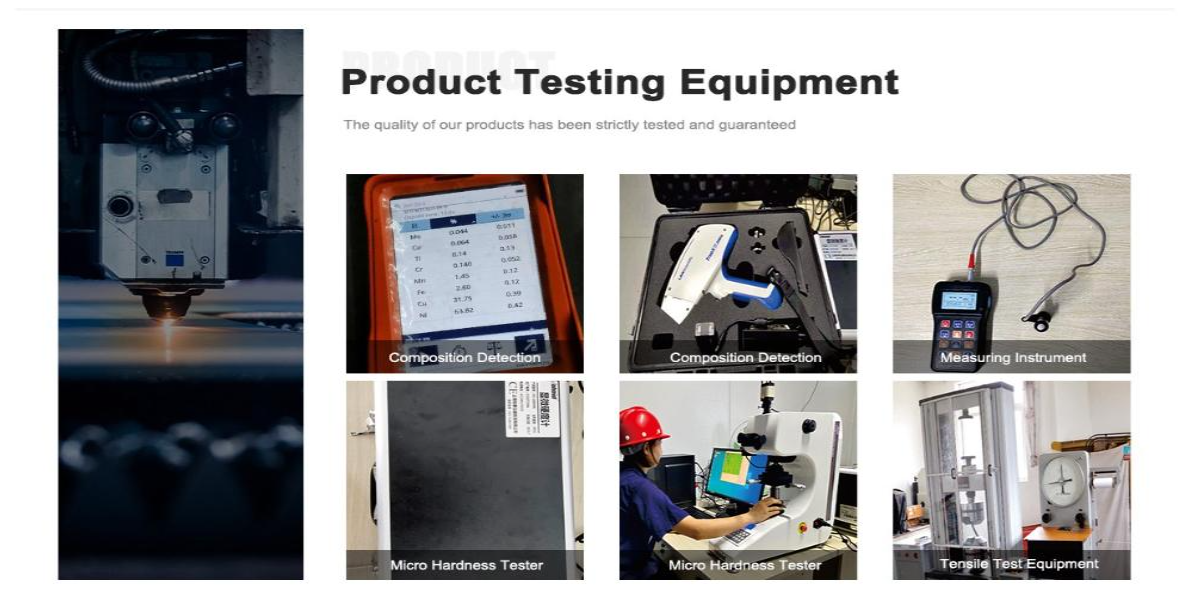

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What are these CuNi alloy bars used for?

They’re great for marine fittings, heating elements, resistors, and structural components.How corrosion-resistant are these bars?

They’re super tough against seawater, acids, and industrial chemicals.What’s the max temperature these bars can handle?

Depending on the alloy, they’re good from 300°C to 600°C.Are these bars magnetic?

Nope, they’re non-magnetic, perfect for sensitive electronics.Can these bars be welded or soldered?

Totally, they weld and solder easily for versatile fabrication.Which industries use these CuNi bars?

Marine, automotive, aerospace, and electronics are the big ones.How do these alloys compare?

CuNi10’s affordable and strong, CuNi30’s great for higher strength, CuNi44 excels in high-heat precision.Are these bars eco-friendly?

They’re fully recyclable and meet standards like RoHS.

-

Wholesale Price Copper Nickel Alloy CuNi8 CuNi 10 Round Rod Bar

Enquire Now -

Good Price Nickel Alloy CuNi8 CuNi10 Round & Square Bar For Sale

Enquire Now -

CuNi2 Bar CuNi Alloy Various CuNi Models CuNi2 CuNi6 Bar/ CuNi44 Rod

Enquire Now -

High Quality Customized CuNi Super Alloy Factory Direct Supply Super Bar CuNi8

Enquire Now