Customized CuNi Copper Nickel Alloy Price CuNi 10 Bar for sale

- Product Details

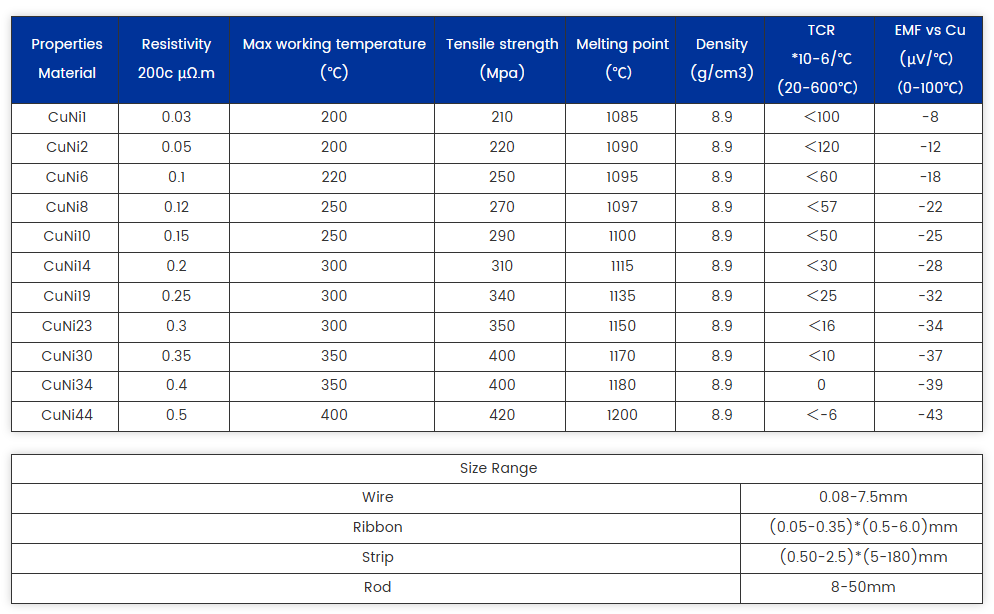

We’re pumped to offer our customized CuNi 10 bars, a copper-nickel alloy with 10% nickel that’s a perfect fit for businesses needing reliable, high-performance materials at a great price. These bars are all about versatility and durability, and we’re excited to share why they’re such a hot item for industrial applications.

CuNi10 is a rockstar for projects that need a solid mix of corrosion resistance and electrical performance. It’s a go-to for heating cables in underfloor systems, marine fittings that stand up to brutal saltwater, and electrical connectors in automotive setups. With a max operating temp of around 350°C, these bars are perfect for moderate-heat environments. Their high ductility makes them super easy to machine, bend, or weld, and the bright, annealed finish ensures smooth fabrication. Plus, they’re non-magnetic, which is a big win for electronics and sensor applications.

The industry’s on fire, with copper-nickel alloys growing at a 5-7% clip annually, driven by electric vehicles, renewable energy, and marine tech. Our CuNi10 bars are showing up in everything from EV battery connectors to offshore platform components. We’re shipping to over 50 countries, backed by ISO:9001 certification, so you know every bar’s top quality. And they’re 100% recyclable, meeting RoHS standards, which keeps our eco-conscious clients happy.

What makes our CuNi10 bars stand out is how we tailor them to your needs. Whether you want a specific diameter, length, or form—wires, strips, or bars—we’ve got you covered. Our R&D team’s always tweaking things to boost conductivity or durability for next-gen applications like smart grids or advanced marine systems. The moderate price point makes CuNi10 a sweet deal compared to high-nickel alloys like CuNi44, without skimping on performance.

CuNi10 isn’t the answer for every job. If you’re dealing with super high temps, CuNi44’s better. Need something dirt-cheap? CuNi2 might be your pick. But for a balance of cost, strength, and corrosion resistance, CuNi10’s hard to beat. It’s a versatile, reliable choice for mid-range applications in tough environments.

CuNi10, too known as Copper Nickel 10, is an combination comprising of roughly 10% nickel and the leftover portion being copper. This amalgam is known for its fabulous combination of mechanical and corrosion-resistant properties. Here’s a nitty gritty outline of its characteristics and applications, especially in bar shape

Properties:

Corrosion Resistance:

Exceptional resistance to corrosion, especially in marine environments. It is highly resistant to seawater and other aggressive corrosive media.

Strength and Durability:

Good mechanical strength and durability, making it suitable for structural applications.

Thermal and Electrical Conductivity:

While lower than pure copper, it still maintains good thermal and electrical conductivity.

Ductility and Workability:

High ductility and workability, allowing it to be easily formed, machined, and fabricated.

Non-Magnetic:

Non-magnetic nature, beneficial for applications requiring non-magnetic materials.

Biofouling Resistance:

Resists biofouling, which is crucial in marine applications.

Applications:

Given its properties, CuNi10 is used in a variety of applications, particularly where corrosion resistance and strength are essential:

Marine Applications:

Commonly used in marine hardware, such as boat hulls, propellers, and seawater piping systems. Its excellent resistance to seawater corrosion makes it ideal for these environments.

Heat Exchangers and Condensers:

Utilized in heat exchangers and condensers, particularly in power plants and desalination plants, due to its thermal conductivity and resistance to corrosion.

Automotive and Aerospace:

Used in automotive and aerospace components that require strength and resistance to harsh environments.

Oil and Gas Industry:

Suitable for use in offshore oil and gas platforms, pipelines, and related equipment.

Electrical Components:

Employed in electrical and electronic components where a combination of conductivity and corrosion resistance is needed.

Desalination Plants:

Extensively used in desalination plants for tubing and piping systems due to its resistance to saline environments.

Industrial Equipment:

Used in various industrial applications, including valves, pumps, and fittings that are exposed to corrosive media.

Specific Form - Rod:

Advantages of Using Rod Form:

Structural Applications: The rod form is particularly useful in structural applications where strength and rigidity are required.

Machining and Fabrication: Rods can be easily machined and fabricated into various components, making them versatile for different applications.

Precision Manufacturing: Suitable for precision manufacturing processes to create custom parts and components.

Overall, CuNi10 rods are highly valued for their excellent combination of corrosion resistance, strength, and thermal/electrical conductivity, making them suitable for a wide range of demanding applications, especially in marine, industrial, and energy sectors.

For more details, pls directly contact us.

About Us:

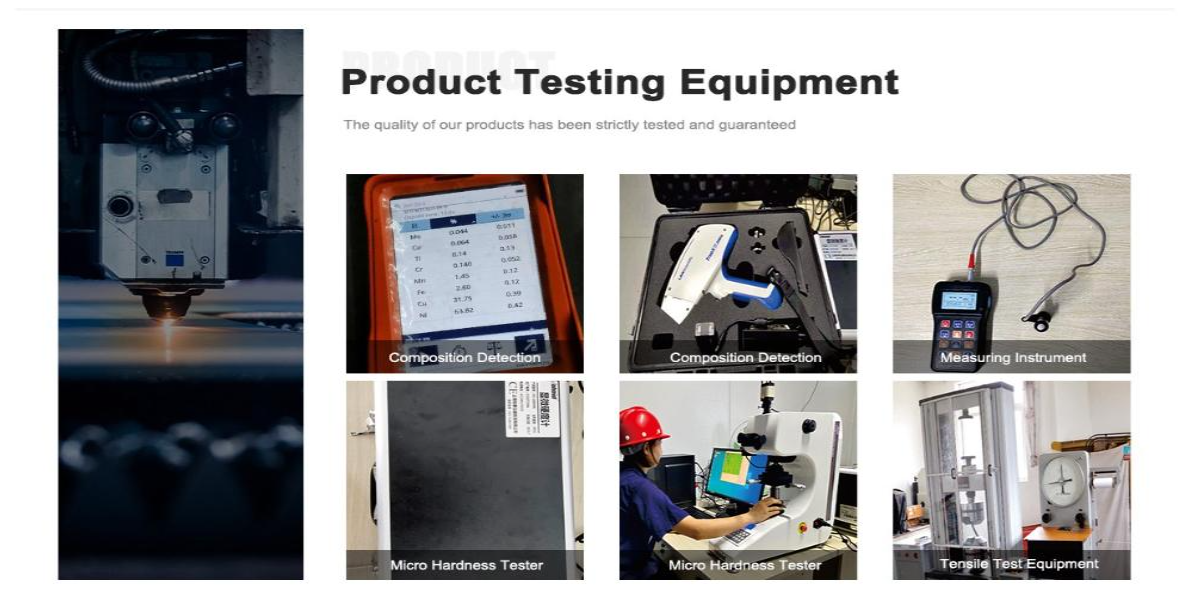

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What’s CuNi10 used for?

It’s ideal for heating cables, marine fittings, and electrical connectors.How corrosion-resistant is CuNi10?

It’s highly resistant to seawater and industrial chemicals.What’s the max temperature CuNi10 can handle?

It’s good up to 350°C for various applications.Is CuNi10 magnetic?

Nope, it’s non-magnetic, great for electronics and sensors.Can CuNi10 be welded or soldered?

Yes, it welds and solders easily, making fabrication a breeze.Which industries use CuNi10 bars?

Marine, automotive, electronics, and renewable energy are the main ones.How does CuNi10 compare to other alloys?

It’s stronger than CuNi2 but cheaper than CuNi44, with solid all-around performance.Is CuNi10 eco-friendly?

It’s recyclable and meets environmental standards like RoHS.

-

Wholesale Price Copper Nickel Alloy CuNi8 CuNi 10 Round Rod Bar

Enquire Now -

Good Price Nickel Alloy CuNi8 CuNi10 Round & Square Bar For Sale

Enquire Now -

CuNi2 Bar CuNi Alloy Various CuNi Models CuNi2 CuNi6 Bar/ CuNi44 Rod

Enquire Now -

High Quality Customized CuNi Super Alloy Factory Direct Supply Super Bar CuNi8

Enquire Now