Polished Pure Tantalum CuNi Bar Tantalum Bar Stock Tantalum Metal Plate Rod Customer Side

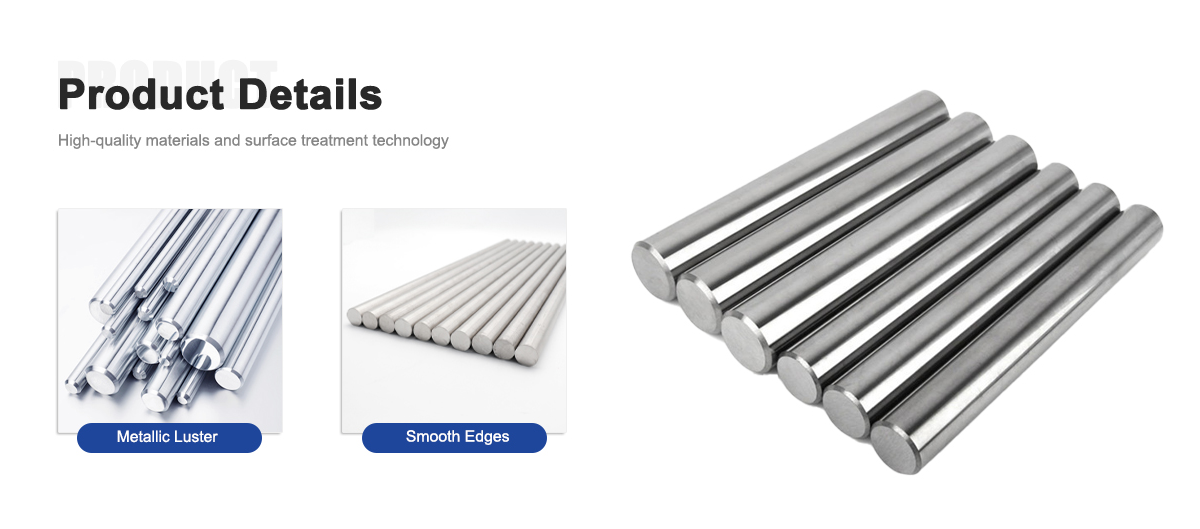

- Product Details

We’re jazzed to offer our polished pure tantalum and CuNi alloy bars, a dynamic duo of high-performance materials ready to tackle your toughest industrial projects. From tantalum’s insane heat resistance to CuNi’s corrosion-fighting prowess, these bars and rods are built to deliver durability and versatility. Let’s break down why they’re a killer choice for your business.

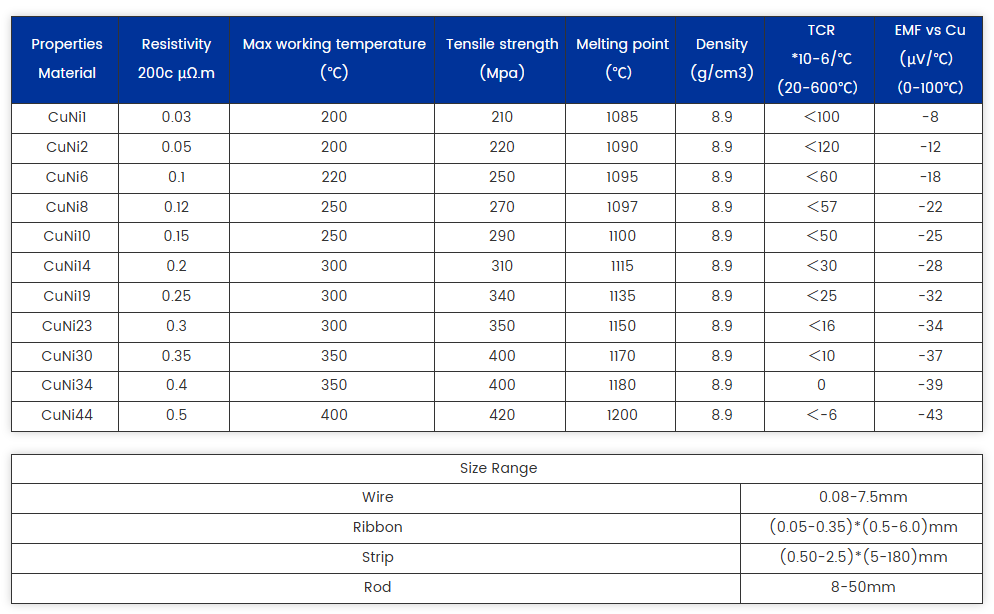

Our polished tantalum bars are the heavy hitters, with a melting point around 3000°C and corrosion resistance that laughs off most acids (except hydrofluoric). They’re perfect for high-stakes applications like capacitors in electronics, medical implants, or aerospace components like rocket nozzles. On the CuNi side, alloys like CuNi10 and CuNi44 bring serious game for heating cables, marine fittings, and precision resistors. CuNi10’s great for moderate-temp jobs like underfloor heating, while CuNi44 handles high-heat tasks like thermocouples, hitting up to 600°C. Both materials are non-magnetic, super ductile, and easy to weld, giving you tons of flexibility to shape them for your needs.

The industry’s on fire, with demand for tantalum and copper-nickel alloys growing 5-7% annually, driven by electronics, aerospace, medical, and renewable energy sectors. Our bars are showing up in everything from EV battery connectors to offshore platform fittings that shrug off saltwater. We source tantalum from Level 1 smelters for DRC conflict-free material and ship to over 50 countries, backed by ISO:9001 certification. Plus, both tantalum and CuNi are 100% recyclable, meeting RoHS standards, which our eco-conscious clients love.

What sets us apart is our customization game. Need a specific diameter, length, or form? We’ve got you covered, from 0.1mm wires to 100mm bars for tantalum or 50mm for CuNi. The polished finish on our tantalum bars reduces gas absorption for high-vacuum applications, while CuNi’s bright finish makes machining a breeze. Our R&D team’s always tinkering, boosting conductivity or durability for next-gen uses like smart electronics or green energy systems.

Tantalum’s the premium pick for extreme heat and biocompatibility but comes at a higher cost. CuNi10’s a cost-effective all-rounder for marine and heating applications, while CuNi44’s your go-to for high-temp precision. Whatever your project—capacitors, implants, or marine gear—we’ve got the expertise to deliver the right bar, tailored to your specs.

Our polished tantalum and CuNi alloy bars aren’t just metal—they’re high-performance solutions to power your business. We’re pumped to craft these durable, versatile bars and help you crush it, from cutting-edge tech to rugged industrial setups.

Specification

For more details, pls directly contact us.

Applications:

One of the main applications of DLX CuNi Alloy is in the marine industry. This alloy is commonly used to manufacture components that are exposed to seawater, such as propellers, heat exchangers, and condensers. Its resistance to corrosion and biofouling makes it ideal for marine applications. DLX CuNi Alloy is also used in oil and gas exploration and production. It is used to make tubing, pipes, and other components that can withstand high pressures and temperatures.

DLX CuNi Alloy is also widely used in power generation. This alloy is used to make components such as heat exchangers, condensers, and boilers that are exposed to high temperatures and pressures. Its thermal conductivity and corrosion resistance make it a popular choice for these applications.

In the chemical processing industry, DLX CuNi Alloy is used to make parts that are exposed to harsh chemicals and high temperatures. The alloy's resistance to corrosion and chemical attack makes it a reliable choice for this industry.

In addition to DLX CuNi Alloy, the DLX brand also offers other alloy products, such as aluminium copper alloy and copper tungsten alloy. These alloys are used in a variety of applications, including aerospace, electronics, and manufacturing.

Support and Services:

CuNi alloy is a highly versatile material used in a wide range of applications. Our technical support team is available to help you with any questions you may have regarding the use, properties, and characteristics of CuNi alloy. We offer a variety of services to support your needs, including: - Material selection guidance - Custom alloy development - Testing and analysis services - Technical consulting Our experienced team of engineers and metallurgists can assist you with any technical challenges you may face, and our state-of-the-art facilities are equipped to handle a range of testing and analysis needs. Contact us to learn more about how we can support your CuNi alloy needs.

Packing and Shipping:

Product Packaging:

Our CuNi alloy products are carefully packed to ensure their safety during transportation. They are usually packaged in wooden cases or pallets with proper cushioning materials to prevent any damage or scratches during transit.

Shipping:

We offer various shipping options to our customers depending on their location and requirements. We work with reliable shipping companies to ensure timely delivery of the products. We also provide tracking information so that our customers can monitor the status of their shipment.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What are polished pure tantalum and CuNi bars used for?

They’re ideal for capacitors, heating elements, marine fittings, and medical implants.How corrosion-resistant are these materials?

Tantalum resists most acids except hydrofluoric; CuNi excels against seawater and chemicals.What’s the max temperature they can handle?

Tantalum handles ~3000°C; CuNi ranges from 200°C to 600°C depending on the alloy.Are these bars magnetic?

Both are non-magnetic, perfect for sensitive electronics and medical devices.Can these bars be welded or soldered?

Yes, both weld and solder easily for versatile fabrication.Which industries use these bars?

Aerospace, electronics, medical, chemical, and marine industries are key.How do tantalum and CuNi alloys compare?

Tantalum’s better for high temps and biocompatibility; CuNi’s more cost-effective for heating and marine uses.Are these materials eco-friendly?

They’re recyclable and often meet standards like RoHS.

-

Wholesale Price Copper Nickel Alloy CuNi8 CuNi 10 Round Rod Bar

Enquire Now -

Good Price Nickel Alloy CuNi8 CuNi10 Round & Square Bar For Sale

Enquire Now -

CuNi2 Bar CuNi Alloy Various CuNi Models CuNi2 CuNi6 Bar/ CuNi44 Rod

Enquire Now -

High Quality Customized CuNi Super Alloy Factory Direct Supply Super Bar CuNi8

Enquire Now