A-grade copper-nickel alloy rods and multifunctional materials for various industrial applications

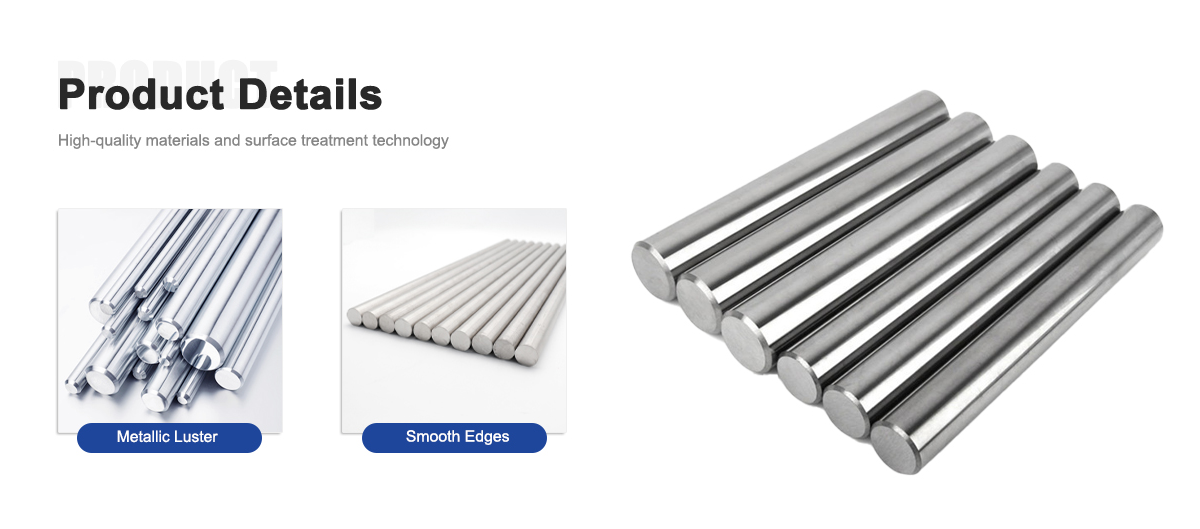

- Product Details

We’re proud to crank out A-grade copper-nickel alloy rods, the kind of versatile, high-performance materials that industries can’t get enough of. These rods—whether CuNi2, CuNi10, or CuNi44—are built to tackle a crazy range of applications, from marine fittings to high-tech electronics. Let’s talk about why our copper-nickel alloys are such a big deal.

Our rods are all about flexibility. Need something for low-temp heating? CuNi2’s got you covered with its low cost and solid resistivity for things like electric blankets or car seat heaters. Want tougher stuff for marine environments or EV connectors? CuNi10 steps up with awesome corrosion resistance and strength. For high-heat jobs like thermocouples in jet engines or precision resistors, CuNi44’s your guy, handling temps up to 600°C without breaking a sweat. All our alloys are non-magnetic, super ductile, and easy to weld, making them a dream to work with.

The industry’s buzzing, and we’re right in the mix. Copper-nickel alloys are seeing 5-7% annual growth, driven by trends like electric vehicles, renewable energy, and aerospace. Our rods are popping up in everything from wind turbine components to ship piping that laughs off saltwater corrosion. We’re shipping to over 60 countries, with ISO:9001 certification ensuring every rod meets top-tier standards. Plus, our alloys are 100% recyclable, aligning with green standards like RoHS, which our eco-conscious clients love.

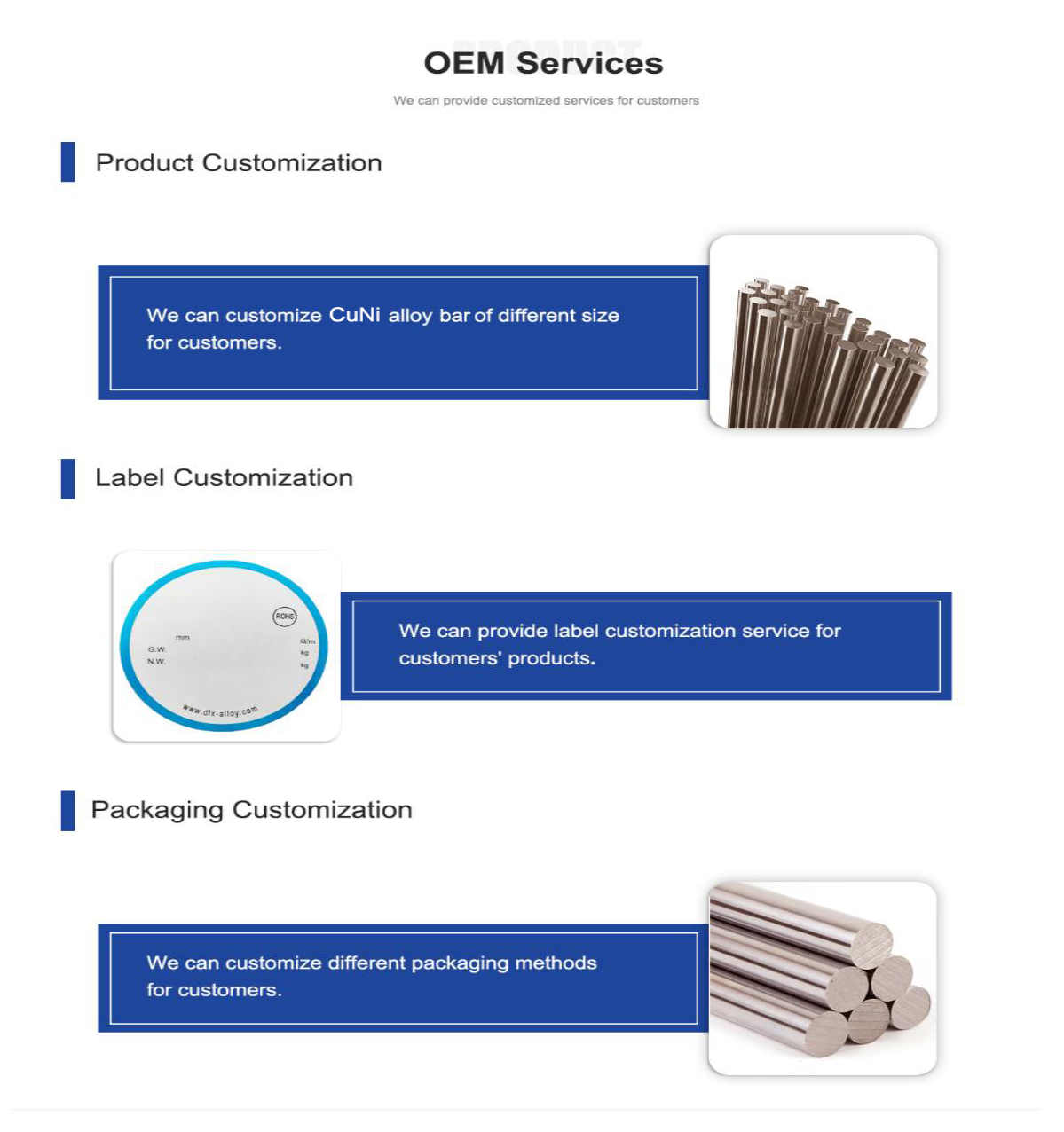

What makes our A-grade rods stand out is our ability to dial them in for your needs. We offer sizes from 0.02mm wires to 50mm rods, with bright, annealed finishes for easy machining. Our OEM expertise means we can customize alloys or forms to fit your project, whether it’s for automotive sensors, industrial furnaces, or marine valves. We’re also pushing boundaries with R&D, tweaking compositions to boost conductivity or durability for next-gen tech like smart grids or advanced aerospace systems.

No alloy’s perfect for every job. CuNi2’s great for budget-friendly projects but taps out at lower temps. CuNi44’s a beast for high-heat precision but costs more and isn’t as flexible. CuNi10? It’s the middle ground, balancing cost and performance. Whatever you need, we’ve got the know-how to deliver the right rod for the job.

Our A-grade copper-nickel alloy rods aren’t just materials—they’re solutions powering industries from the ocean to the skies. We’re stoked to keep crafting these multifunctional workhorses and helping our clients build a stronger, smarter future.

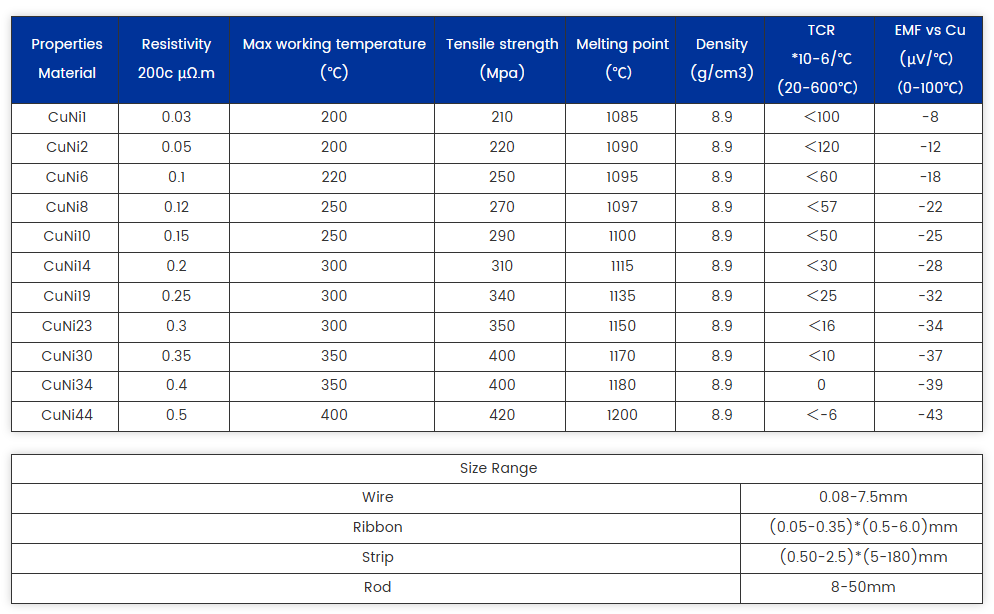

Specification

For more details, pls directly contact us.

Product Description:

Our CuNi Alloy product can withstand high-temperature applications, with a maximum temperature limit of 350℃, making it an excellent choice for use in high-temperature environments. It is also bright in surface appearance, providing a clean and polished finish that is aesthetically pleasing.

This alloy has a hardness of 120-180 HV, which is moderate and suitable for various industrial and manufacturing purposes. It is also highly durable, providing long-lasting performance even in harsh conditions.

The CuNi Alloy product is widely used in electrical and electronic industries, including power generation, telecommunications, and automation systems. Its superior electrical conductivity makes it an ideal choice for electrical connectors, switches, and relays. It is also used in heating applications such as heating elements, resistors, and thermocouples.

Compared to other alloys such as Aluminium Copper Alloy and Copper Tungsten Alloy, our CuNi Alloy product offers superior corrosion resistance and has a lower thermal expansion coefficient. This makes it an excellent choice for applications that require stable and reliable performance over time.

In summary, our CuNi Alloy product is a versatile and durable material that offers exceptional electrical conductivity and corrosion resistance. Its bright surface, moderate hardness, and high-temperature resistance make it an excellent choice for various industrial and manufacturing applications.

Applications:

The copper nickel alloy is used to make alloy parts in the automotive industry, aerospace industry, and marine industry. The products are used to make heat exchangers, condensers, evaporators, and other parts that require resistance to corrosion and erosion.

The product is also used in the manufacturing of Copper Tungsten Alloy, which is used in the electrical and electronic industries. Copper tungsten alloy is used to make electrical contacts, resistance welding electrodes, and other electrical components.

DLX CuNi Alloy is also used in the chemical industry to make equipment that can withstand high temperatures and pressures. The alloy is also used to make valves, pumps, and other parts that require resistance to corrosion and erosion.

The product is also used in the construction industry to make architectural features, sculptures, and other decorative elements. The alloy is also used in the manufacture of musical instruments, such as brass instruments, due to its excellent acoustic properties.

In conclusion, DLX CuNi Alloy is a versatile product that finds its application in various industries due to its excellent resistance to corrosion and erosion. The product is used to make alloy parts, copper nickel alloy, copper tungsten alloy, and other electrical and electronic components. The product is manufactured in China and is suitable for use in the automotive industry, aerospace industry, marine industry, chemical industry, construction industry, and musical instruments industry.

Support and Services:

Our CuNi Alloy product technical support and services include:

Expert advice on product selection and application

Customized product development for specific needs

Technical data sheets and material safety data sheets

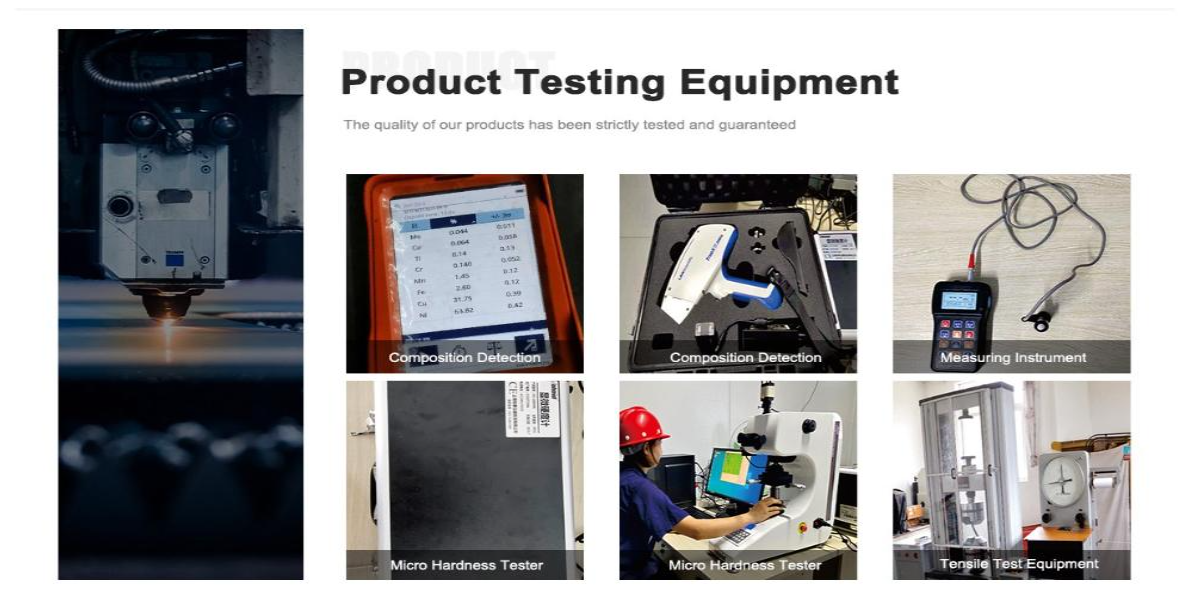

Quality control and testing

Product training and education

Post-sales support and troubleshooting

Packing and Shipping:

Product Packaging:

Each CuNi Alloy product will be securely packed in a cardboard box.

The box will be labeled with the product name, quantity, and any necessary handling instructions.

If multiple products are ordered, they will be packaged together in the same box.

Product Shipping:

We offer worldwide shipping for all CuNi Alloy products.

Shipping rates will vary depending on the destination and the size of the order.

All orders will be shipped within 3-5 business days after payment has been received.

We use trusted shipping carriers to ensure safe and timely delivery of your order.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What are A-grade copper-nickel alloy rods used for?

They’re used in marine fittings, heating elements, resistors, and electrical connectors.How corrosion-resistant are these alloys?

They’re top-notch, especially against seawater and industrial chemicals.What’s the temperature range for these rods?

Depending on the alloy, they handle from 200°C to 600°C.Are copper-nickel alloys magnetic?

Nope, they’re non-magnetic, great for sensitive electronics.Can these rods be welded or soldered?

Yes, they’re easy to weld and solder for flexible fabrication.Which industries use these rods?

Marine, automotive, aerospace, electronics, and renewable energy are key.How do these alloys compare to others?

They balance cost, strength, and performance, with options like CuNi2 for low-cost or CuNi44 for high-heat needs.Are these alloys eco-friendly?

They’re fully recyclable and meet standards like RoHS

-

Wholesale Price Copper Nickel Alloy CuNi8 CuNi 10 Round Rod Bar

Enquire Now -

Good Price Nickel Alloy CuNi8 CuNi10 Round & Square Bar For Sale

Enquire Now -

CuNi2 Bar CuNi Alloy Various CuNi Models CuNi2 CuNi6 Bar/ CuNi44 Rod

Enquire Now -

High Quality Customized CuNi Super Alloy Factory Direct Supply Super Bar CuNi8

Enquire Now