Bright Resistance Alloy Copper Nickel Cuni2 Rod Manufacturer

- Product Details

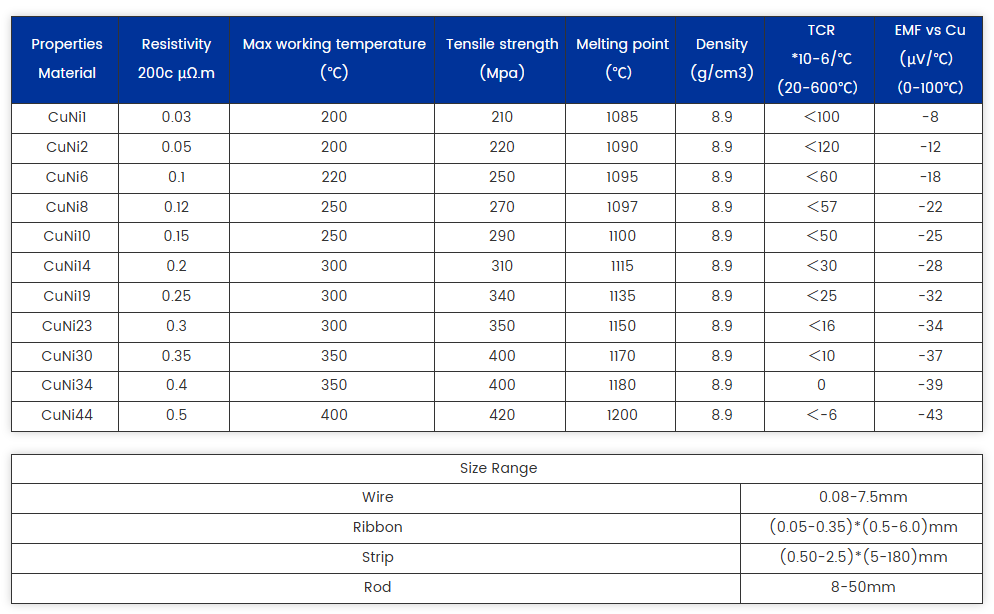

CuNi Series

DLX alloy offer CuNi2 Copper Alloys, and it consists of Copper (Bal) as primary components. Additionally, CuNi2 alloy may have Nickel (0.7% - 2.2%), Nickel (0.7% - 2.2%) in trace amounts.

CuNi2 (2.0802) is a copper-nickel alloy (CuNi alloy) with low resistivity for use at temperatures up to 300℃. CuNi2 is used for heating resistance alloy products Copper nickel alloy CuNi 1 have low resistance, and working temperature upto 200 degree. CuNi2 Copper nickel alloy also has good corrosion-resistant, It is easy to be processed and lead welded. CuNi2 is used to make the key components in the thermal overload relay, low resistance thermal circuit breaker, and the electrical appliances. It is also an important material for electrical heating cable.

We’re proud to be a leading manufacturer of CuNi2 rods, a copper-nickel alloy that’s got a solid rep in the industry. This stuff is a workhorse—low resistivity, great corrosion resistance, and super easy to work with. Let’s break it down and tell you why CuNi2 is a big deal for us and our customers.

CuNi2, with its 2% nickel content, is our go-to for low-temperature applications. Think heating cables in electric blankets, resistors in car seats, or even low-voltage circuit breakers. It’s got this sweet spot of electrical performance that makes it perfect for these kinds of jobs. Plus, it’s tough against corrosion, especially in salty, marine environments. That’s why you’ll find it in everything from ship components to offshore platforms. It’s like the alloy equivalent of a reliable pickup truck—affordable, durable, and gets the job done.

What makes CuNi2 stand out is its versatility. We produce it in rods, wires, and strips, with sizes ranging from super fine (0.02mm wires) to chunky (30mm rods). It’s bright, annealed, and soft, so it’s a breeze to shape or weld. And let’s talk cost—it’s one of the most budget-friendly copper-nickel alloys out there. Compared to something like CuNi44, which has way more nickel, CuNi2 gives you solid performance without breaking the bank. Our customers in automotive and electronics love it for that reason.

The industry’s moving fast, and we’re keeping up. Demand for CuNi2 is growing, especially with the push for electric vehicles and renewable energy. Think battery pack connectors or components in wind turbines—CuNi2’s corrosion resistance and conductivity make it a natural fit. We’re also seeing more automation in manufacturing, like resistance welding systems, where CuNi2 rods shine as electrodes. Sustainability’s a big deal too. Our production processes are dialed in to meet strict environmental regs like RoHS, and the alloy itself is fully recyclable, which keeps our eco-conscious clients happy.

We’re not just churning out rods; we’re innovating. Our team’s constantly tweaking alloy compositions to boost performance, like improving conductivity for next-gen electronics or refining surface finishes for precision applications. The market’s hot—reports say copper-nickel alloys are growing at a 5-6% CAGR, driven by marine, automotive, and energy sectors. We’re right in the thick of it, supplying to over 50 countries and working with industries that need reliable, high-quality materials.

Sure, CuNi2 isn’t perfect for every job. If you need something for super high temperatures or extreme strength, we’d point you to CuNi44 or even a nickel-chromium alloy. But for low-to-medium temp applications, CuNi2’s hard to beat. It’s non-magnetic, stable, and doesn’t flinch in harsh environments. We’ve got the production know-how to deliver it in whatever form you need, backed by ISO:9001 certification and a supply chain that’s as solid as our rods.

So, whether you’re building heating systems, automotive parts, or marine gear, our CuNi2 rods are ready to roll. It’s not just metal—it’s a solution that’s helping power the future, and we’re stoked to be part of it.

For more details, pls directly contact us.

Properties:

Composition:

CuNi2 consists of approximately 2% nickel and the remainder is copper.

The small amount of nickel enhances the alloy's strength and corrosion resistance compared to pure copper.

Bright Finish:

The "bright" finish indicates a polished or smooth surface, which can be achieved through processes like annealing, polishing, or electroplating.

This finish not only enhances the aesthetic appeal but also reduces oxidation and corrosion.

Resistance Properties:

Exhibits good electrical resistivity, making it suitable for applications requiring controlled resistance.

The resistivity is stable over a wide range of temperatures, which is critical for precision electrical components.

Corrosion Resistance:

Excellent resistance to corrosion, especially in marine and industrial environments.

Resists biofouling and oxidation, maintaining its appearance and structural integrity over time.

Mechanical Strength:

Good mechanical strength and durability, with moderate tensile strength.

Can be enhanced through work hardening for specific applications.

Thermal Conductivity:

Maintains good thermal conductivity, useful in heat exchange applications.

Applications:

Electrical Components:

Used in the manufacture of precision resistors, connectors, and other electrical components where stable resistance is required.

Suitable for applications in electrical engineering and electronics where controlled resistance and reliability are important.

Heating Elements:

Employed in heating elements for industrial and domestic applications due to its stable resistive properties.

Marine Applications:

Ideal for marine hardware and components, such as fasteners, fittings, and propellers, due to its corrosion resistance and bright finish.

Used in seawater cooling and piping systems.

Automotive and Aerospace:

Utilized in automotive and aerospace industries for components that require both strength and resistance to harsh environments.

Used in decorative and functional trim parts due to its bright appearance and durability.

Instrumentation:

Suitable for precision instrumentation and measurement devices where consistent electrical properties are crucial.

Used in strain gauges and other sensitive equipment.

Industrial Equipment:

Employed in various industrial applications, including valves, pumps, and fittings, where corrosion resistance and durability are necessary.

Maintenance:

The bright finish can be maintained through regular cleaning to prevent tarnishing and oxidation.

Protective coatings or treatments can further enhance the longevity and appearance of the rod.

Overall, a bright resistance alloy copper-nickel CuNi2 rod is a versatile material that combines aesthetic appeal with functional properties like electrical resistivity, corrosion resistance, and mechanical strength. This makes it suitable for a wide range of demanding applications across various industries.

About Us:

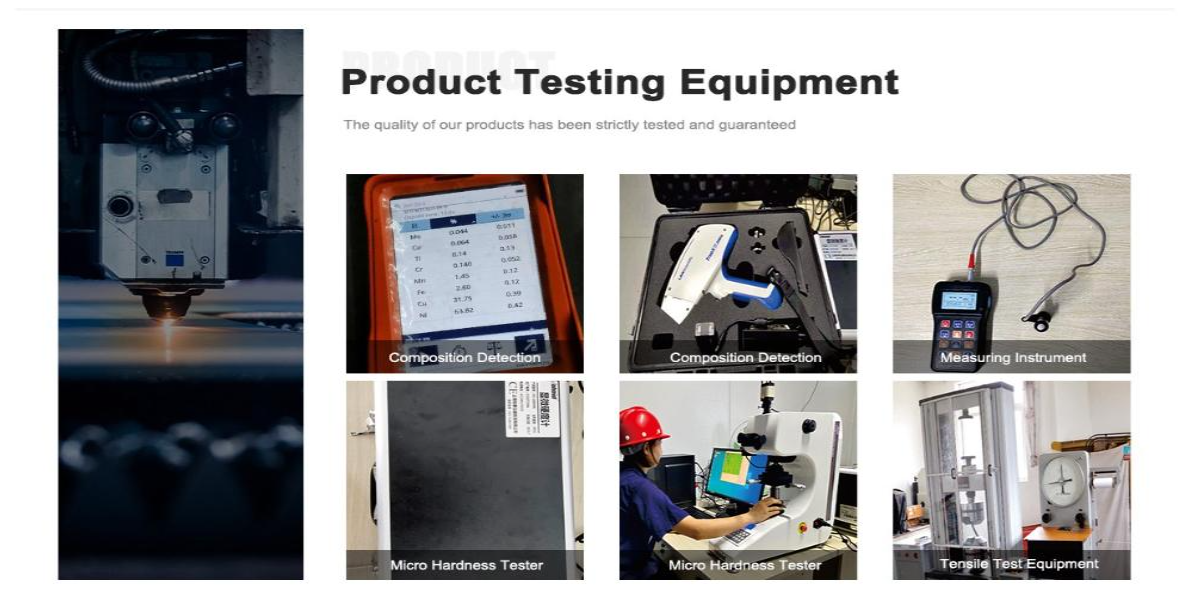

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What is CuNi2 alloy used for?

It’s mainly used in low-temperature heating applications like electric blankets, heating cables, and automotive resistors.

How resistant is CuNi2 to corrosion?

It’s highly resistant, particularly to seawater and atmospheric corrosion, making it ideal for marine and industrial use.

What’s the max operating temperature for CuNi2?

It can handle temperatures up to 200°C, sometimes 300°C for specific applications.

Is CuNi2 magnetic?

No, it’s non-magnetic, which is great for applications needing minimal magnetic interference.

Can CuNi2 be welded or soldered?

Yes, it’s easily welded and soldered, offering good fabrication flexibility.

What industries rely on CuNi2 rods?

Automotive, electronics, marine, and heating industries are the big ones.

How does CuNi2 compare to other copper-nickel alloys?

It’s lower in nickel (2%), so it’s cheaper but less suited for high-temperature or high-strength needs compared to CuNi44.

Is CuNi2 environmentally friendly?

It’s recyclable and complies with regulations like RoHS, making it a sustainable choice.

-

Wholesale Price Copper Nickel Alloy CuNi8 CuNi 10 Round Rod Bar

Enquire Now -

Good Price Nickel Alloy CuNi8 CuNi10 Round & Square Bar For Sale

Enquire Now -

CuNi2 Bar CuNi Alloy Various CuNi Models CuNi2 CuNi6 Bar/ CuNi44 Rod

Enquire Now -

High Quality Customized CuNi Super Alloy Factory Direct Supply Super Bar CuNi8

Enquire Now