Corrosion Resistant Copper Nickel Alloy Bar 23% Nickel 120-180 HV Hardness

- Product Details

We’re thrilled to roll out our corrosion-resistant CuNi alloy bars with 23% nickel and a hardness of 120-180 HV. These bars are high-performance, versatile, and built to tackle tough industrial challenges. Let’s dive into why these bars are a go-to for businesses looking for durability and precision.

With 23% nickel, these CuNi bars strike a perfect balance of strength and workability. Their 120-180 HV hardness makes them tough enough for demanding environments yet easy to machine or weld. They’re ideal for marine fittings that face brutal seawater, precision resistors in electronics, or heating elements in industrial systems. The stable electrical properties and corrosion resistance make them a solid choice for applications up to 450°C, from EV battery components to chemical plant gear.

The industry’s buzzing, and we’re right in the thick of it. Copper-nickel alloys are growing at a 5-7% annual rate, driven by trends in marine tech, electric vehicles, and renewable energy. Our bars are showing up in offshore platforms, automotive sensors, and wind turbine components. We supply to over 50 countries, backed by ISO:9001 certification, ensuring every bar’s top quality. Plus, they’re 100% recyclable, aligning with RoHS standards, which our eco-conscious clients love.

What sets our CuNi bars apart is their customizability. From thin wires to thick bars, we can tailor sizes and forms to fit your project. The bright finish ensures smooth fabrication, and that 120-180 HV hardness gives you the durability you need without sacrificing flexibility. Our R&D team’s always tweaking alloys to boost performance for next-gen applications like smart electronics or green energy systems.

These bars aren’t perfect for every job. If you need ultra-high heat resistance, CuNi44’s your pick. On a tight budget? CuNi10 might be better. But with 23% nickel, our bars offer a sweet spot of strength, corrosion resistance, and cost for mid-to-high temp applications. Their non-magnetic properties and stable performance make them a favorite for precision-driven projects.

Our CuNi alloy bars with 23% nickel and 120-180 HV hardness are more than just metal—they’re reliable solutions for businesses pushing the envelope. We’re stoked to craft these bars and help our clients power up their projects, from the ocean depths to the cutting edge of tech.

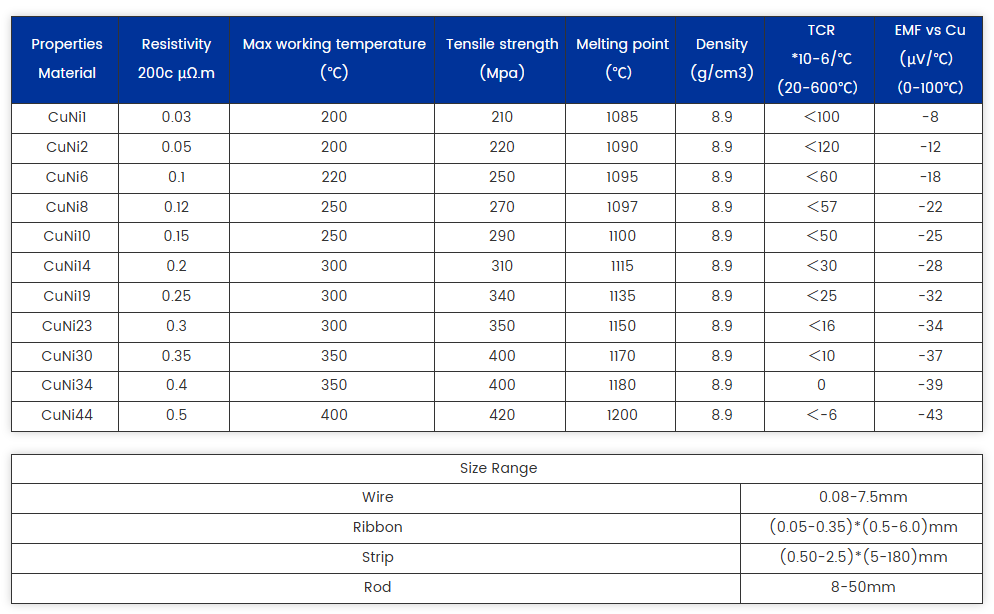

Specification

For more details, pls directly contact us.

Product Description:

One of the most notable features of this CuNi Alloy product is its non-magnetic properties. This attribute makes it an excellent option for applications where magnetic interference is a concern, or where non-magnetic properties are required in the final product.

The alloy is composed of 23% nickel, which helps to provide many of its unique properties, including its excellent resistance to corrosion, oxidation, and high-temperature environments. This composition makes it a perfect choice for industries such as chemical processing, marine, and aerospace.

Our CuNi Alloy product is available in both hard and soft conditions, making it a versatile material choice for various manufacturing processes. Its hardness ranges from 120-180 HV, which allows it to be used for both high-stress and low-stress applications.

With its unique combination of properties, our CuNi Alloy product is an excellent choice for manufacturing alloy parts. Whether it's for use in automotive, electrical, or industrial applications, this alloy has the strength and durability you need. Its corrosion-resistant properties make it an excellent choice for marine applications, while its high-temperature resistance makes it a reliable option for aerospace and chemical processing applications.

In summary, our CuNi Alloy product is a versatile and reliable material choice for anyone in need of strong and durable copper metal products. Its non-magnetic properties, high-temperature resistance, and corrosion-resistant properties make it an excellent option for a wide range of applications. Whether you're in the automotive, electrical, or industrial industries, our CuNi Alloy product is an excellent choice for your alloy parts needs.

Applications:

The CuNi Alloy is widely used in different industries due to its unique properties. It finds use in the production of electrical parts, such as contacts, switches, and connectors. Thanks to its non-magnetic properties, it is also used in sensitive measuring instruments and devices. The alloy's good resistance to corrosion and high temperatures makes it suitable for use in the marine industry, particularly for manufacturing valves, pipes, and heat exchangers.

Another area where CuNi Alloy finds application is in the production of alloy parts. The material's high strength and good machinability make it a preferred choice for manufacturing gears, bearings, and other mechanical components. Its unique properties also make it suitable for use in the production of welding electrodes, resistance wires, and heating elements.

The CuNi Alloy is an ideal material for use in the aerospace industry. With its good resistance to high temperatures and corrosion, it is used in the production of various components in aircraft, such as engine parts, landing gear components, and hydraulic systems. It is also used in the production of rocket motor parts, particularly because of its ability to withstand high temperatures and pressures.

DLX CuNi Alloy is a reliable product, manufactured in China, and is widely used for different applications. Its unique properties make it a preferred choice for many industries, including the electrical, marine, aerospace, and mechanical industries.

Support and Services:

CuNi Alloy is a type of alloy that is used in various industrial applications. As a supplier of this product, we offer technical support and services to ensure that our customers receive the best possible performance from our product. Our technical support team is available to answer any questions or concerns that you may have about the product, including its properties, compatibility, and installation. We also provide comprehensive documentation and product specifications to help you get the most out of your CuNi Alloy purchase. Additionally, we offer a range of services to support our customers, including customized fabrication and machining, product testing, and quality assurance. Our goal is to provide you with a seamless experience and ensure that you are completely satisfied with your purchase of CuNi Alloy.

Packing and Shipping:

Product Packaging:

The CuNi alloy product will be packed in a sturdy cardboard box to ensure safe transportation.

The box will be labeled with the product name, quantity, and any other relevant information.

Each product will be individually wrapped in protective material to prevent any damage during transportation.

The packaging will be designed to withstand any potential impact or rough handling during shipping.

Shipping:

The CuNi alloy product will be shipped via a reputable courier service.

The delivery time will depend on the destination and the selected shipping method.

The customer will be provided with a tracking number to monitor the shipment's progress.

In case of any issues or delays, the customer service team will be available to provide assistance.

If the product arrives damaged, the customer can contact the customer service team to arrange for a replacement or a refund.

About Us:

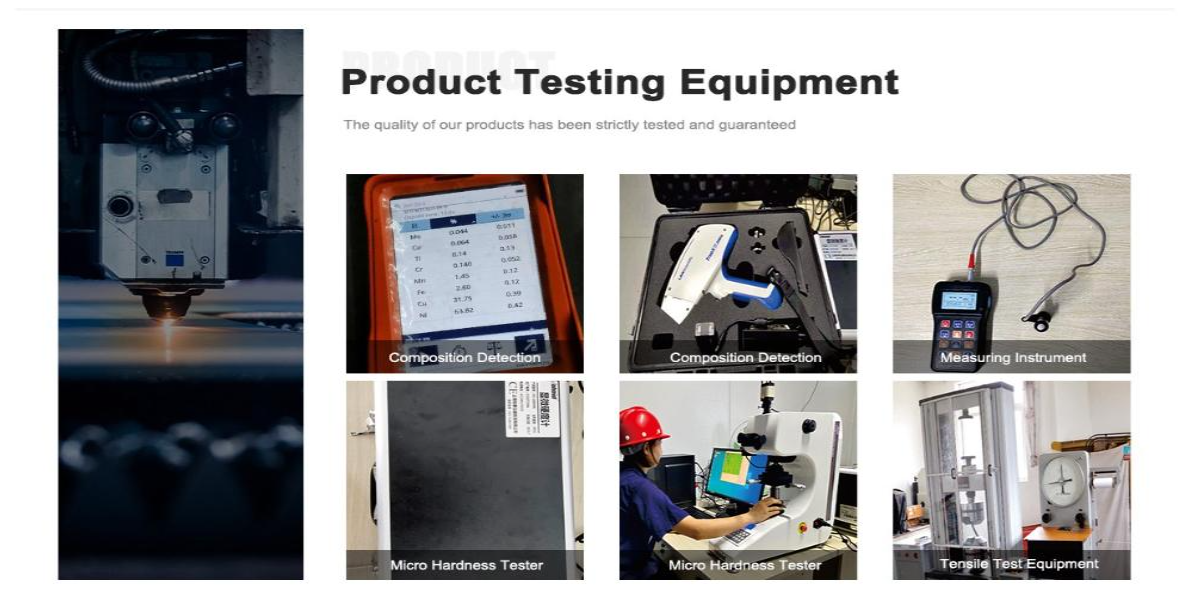

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What’s this 23% Ni CuNi alloy bar used for?

It’s great for marine fittings, precision resistors, and heating elements.How corrosion-resistant is this alloy?

It’s super tough against seawater, acids, and industrial chemicals.What’s the max temperature it can handle?

It’s reliable up to 450°C for various applications.Is this alloy magnetic?

Nope, it’s non-magnetic, perfect for electronics and sensors.Can these bars be welded or soldered?

Yes, they weld and solder easily for flexible fabrication.Which industries use these alloy bars?

Marine, electronics, automotive, and renewable energy are key players.How does this alloy compare to other CuNi alloys?

With 23% Ni, it’s stronger than CuNi10 but more cost-effective than CuNi44.Is this alloy eco-friendly?

It’s fully recyclable and meets standards like RoHS.

-

Wholesale Price Copper Nickel Alloy CuNi8 CuNi 10 Round Rod Bar

Enquire Now -

Good Price Nickel Alloy CuNi8 CuNi10 Round & Square Bar For Sale

Enquire Now -

CuNi2 Bar CuNi Alloy Various CuNi Models CuNi2 CuNi6 Bar/ CuNi44 Rod

Enquire Now -

High Quality Customized CuNi Super Alloy Factory Direct Supply Super Bar CuNi8

Enquire Now