CuNi Alloy Bar The Perfect Combination of Strength and Versatility for Your Business

- Product Details

We’re thrilled to roll out our CuNi alloy bars, a killer combo of strength and versatility that’s ready to power up your industrial projects. Whether you’re working with CuNi2, CuNi10, or CuNi44, these bars are built to deliver top-notch performance across a ton of applications. Let’s dive into why these bars are such a big deal for your business.

Our CuNi bars are all about getting it done, no matter the challenge. CuNi2’s your budget-friendly pick for low-temp jobs like heating cables in electric blankets or resistors in car electronics. Need something tougher for marine or automotive applications? CuNi10 brings serious corrosion resistance and strength to the table, perfect for ship fittings or EV connectors. And when it comes to high-heat precision, CuNi44’s the boss, handling up to 600°C for things like thermocouples in aerospace or high-end resistors. These bars are super formable, non-magnetic, and a breeze to weld, giving you the flexibility to create exactly what you need.

The industry’s buzzing, and we’re right in the thick of it. Copper-nickel alloys are growing at a 5-7% clip annually, fueled by electric vehicles, renewable energy, and marine tech. You’ll find our bars in everything from wind turbine components to offshore platform fittings that shrug off saltwater corrosion. We’re shipping to over 60 countries, backed by ISO:9001 certification, ensuring every bar’s top quality. Plus, they’re 100% recyclable, meeting RoHS standards, which our eco-conscious clients totally dig.

What makes our CuNi bars stand out is how we tailor them to your needs. From 0.1mm wires to 50mm bars, we can customize sizes, forms, or even alloy tweaks to match your project. The bright, annealed finish makes machining a snap, and our R&D team’s always pushing the limits, fine-tuning alloys for better strength or conductivity in next-gen applications like smart grids or advanced electronics.

Each alloy’s got its vibe. CuNi2 keeps costs low but isn’t built for high heat. CuNi10’s a solid all-rounder for strength and affordability. CuNi44’s your go-to for extreme temps and precision but comes with a higher price tag. Whatever you’re working on, we’ve got the know-how to deliver the right bar for the job.

Our CuNi alloy bars aren’t just metal—they’re a powerhouse of strength and versatility to boost your business. We’re pumped to craft these solutions and help you tackle your toughest industrial challenges, from the factory floor to the high seas.

Product Description:

One of the most significant attributes of the CuNi Alloy is its excellent corrosion resistance. It can withstand harsh environments and corrosive substances, making it an ideal material for marine applications, heat exchangers, and desalination plants. Additionally, it has a bright surface finish that can be easily maintained, making it a practical choice for decorative purposes.

Another important attribute of the CuNi Alloy is its EMF vs Cu of -18 µV/°C. This means that it has a low thermoelectric voltage, making it less susceptible to galvanic corrosion when in contact with copper. This attribute is particularly useful in applications where the alloy comes in contact with copper, such as in copper alloy Bars.

The CuNi Alloy has a density of 8.94 g/cm3, which is relatively high compared to other alloys. This high density makes it a durable and sturdy material, suitable for applications that require strength and resilience.

In conclusion, the CuNi Alloy is a versatile and reliable material that offers excellent corrosion resistance, durability, and a bright surface finish. Its composition of copper and nickel makes it an ideal choice for various industrial applications, including marine, heat exchangers, desalination plants, and copper alloy Bars. If you're looking for a dependable alloy steel metal, the CuNi Alloy is an excellent choice.

Features:

Product Name: CuNi Alloy

Resistivity: 0.5

Density: 8.94 G/cm3

Composition: Copper And Nickel

Maximum Temperature: 200℃

Emf Vs Cu: -18 UV/C

Alloy Steel Material

Alloy Steel Metal

Copper Based Alloys

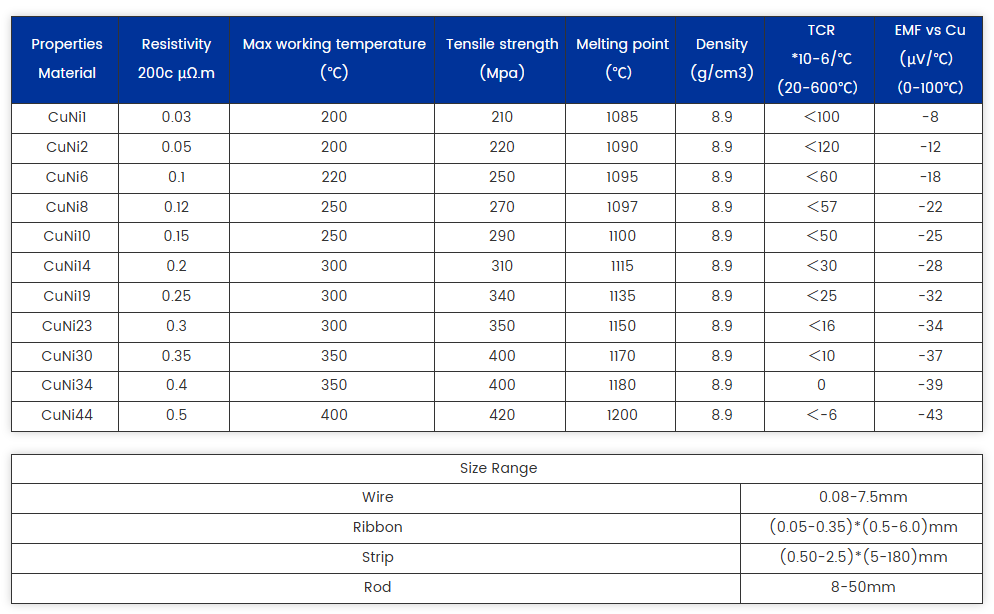

Technical Parameters:

For more details, pls directly contact us.

Applications:

One of the most common uses for CuNi Alloy is in the production of Copper Powder Metallurgy. This process involves the mixing of copper powder with a small amount of CuNi Alloy, which enhances the strength and durability of the final product. This technique is often used in the production of electrical components, such as connectors and switches, where a high level of conductivity and reliability is required.

The DLX CuNi Alloy is also ideal for use in the manufacture of Alloy Steel Metal. This process involves adding small amounts of CuNi Alloy to steel to improve its strength and corrosion resistance. This technique is often used in the automotive and construction industries, where the strength and durability of materials are crucial.

Another common use of CuNi Alloy is in the production of valves, pumps, and other components for the oil and gas industry. The high corrosion resistance and durability of this alloy make it an ideal choice for use in harsh environments, such as deep-sea drilling rigs and offshore platforms.

Overall, DLX CuNi Alloy is a versatile and reliable product that is used in a wide range of applications, from electrical components to heavy-duty machinery. Its excellent strength, corrosion resistance, and durability make it an ideal choice for use in demanding environments and applications.

Customization:

Customize your CuNi Alloy product from DLX, a trusted brand in aluminium copper alloy. Our CuNi Alloy, also known as copper-nickel alloy, is a copper-based alloy that offers excellent resistance to corrosion and high temperatures. Originating from China, our CuNi Alloy has a resistivity of 0.5 and an EMF vs Cu of -18 UV/C. You can choose between hard or soft condition, with a hardness range of 80-120 HV. The density of our CuNi Alloy is 8.94 G/cm3.

Support and Services:

Our CuNi alloy product technical support and services include:

Expert guidance on product selection and application

Assistance with technical and performance specifications

Recommendations for maintenance and care

Training and education on product use and best practices

Technical troubleshooting and problem-solving

Access to product documentation, including data sheets and material safety data sheets

Product customization and tailored solutions

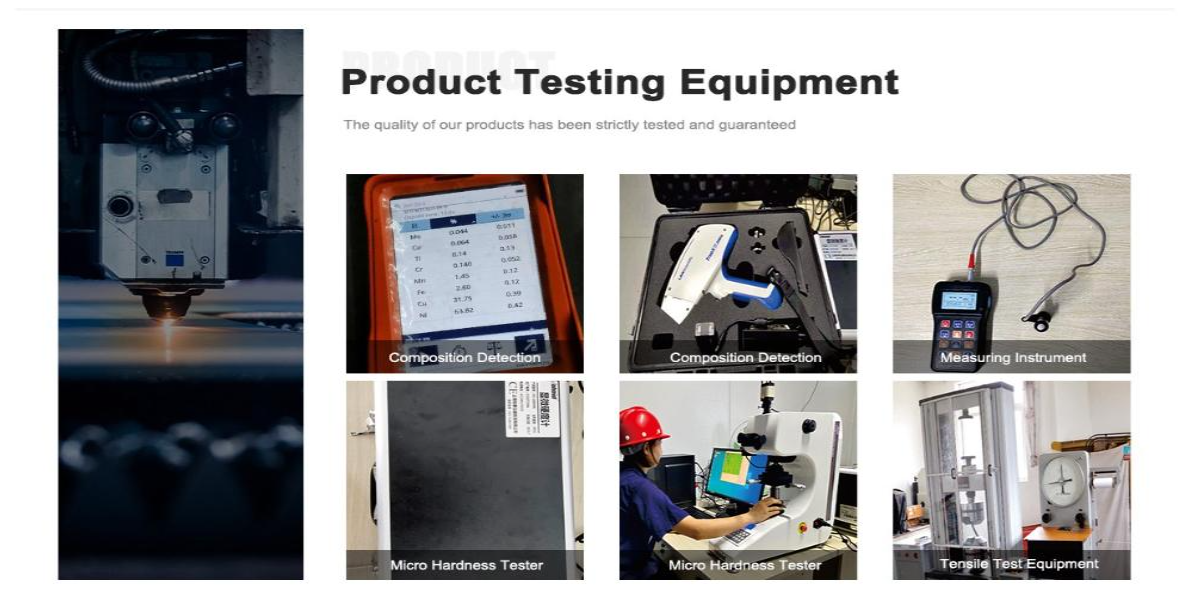

Product testing and analysis

Quality control and assurance

Packing and Shipping:

Product Packaging:

The CuNi Alloy product will be securely packaged in a cardboard box.

The box will be filled with cushioning material to prevent any damage during shipping.

The product will be sealed in a plastic bag to protect it from moisture.

A label with the product information and handling instructions will be attached to the box.

Shipping Information:

The CuNi Alloy product will be shipped via a reputable courier service.

The shipping cost will be calculated based on the weight and destination of the package.

The estimated delivery time will depend on the courier service and destination.

A tracking number will be provided once the package is shipped.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What are CuNi alloy bars used for?

They’re ideal for marine fittings, heating elements, resistors, and thermocouples.

How corrosion-resistant are these bars?

They’re super tough against seawater, acids, and industrial chemicals.

What’s the max temperature these bars can handle?

Depending on the alloy, they work from 200°C to 600°C.

Are CuNi alloy bars magnetic?

No, they’re non-magnetic, great for sensitive electronics.

Can these bars be welded or soldered?

Yep, they’re easy to weld and solder for flexible fabrication.

Which industries use CuNi bars?

Marine, automotive, aerospace, electronics, and renewable energy are key.

How do these alloys compare to each other?

CuNi2 is cost-effective, CuNi10 balances strength and price, CuNi44 is best for high-heat precision.

Are these bars eco-friendly?

They’re fully recyclable and meet standards like RoHS.

-

Wholesale Price Copper Nickel Alloy CuNi8 CuNi 10 Round Rod Bar

Enquire Now -

Good Price Nickel Alloy CuNi8 CuNi10 Round & Square Bar For Sale

Enquire Now -

CuNi2 Bar CuNi Alloy Various CuNi Models CuNi2 CuNi6 Bar/ CuNi44 Rod

Enquire Now -

High Quality Customized CuNi Super Alloy Factory Direct Supply Super Bar CuNi8

Enquire Now