High Purity CuNi Alloy Rods with Hardness of 80-120 HV and Maximum Temperature of 200C

- Product Details

We’re excited to roll out our high purity CuNi alloy rods, featuring a hardness of 80-120 HV and a max temp of 200°C. These rods, with a low 2% nickel content, are perfect for businesses looking for reliable, cost-effective solutions for low-temperature applications. Let’s dive into why these rods are such a solid choice.

These CuNi rods are all about delivering consistent performance in lighter-duty settings. They’re a go-to for heating cables in things like electric blankets or low-power floor heating, as well as electrical connectors in consumer electronics. Their high purity ensures stable electrical properties, and the 80-120 HV hardness makes them a breeze to machine, bend, or weld. Plus, they hold up great against moisture and mild corrosion, which is perfect for indoor or less harsh environments.

The industry’s moving fast, and we’re keeping up. Copper-nickel alloys are seeing steady growth—around 5-6% annually—driven by demand in electronics, automotive, and consumer goods. Our rods are popping up in everything from car seat heaters to HVAC system components. We’re shipping to over 40 countries, with ISO:9001 certification ensuring every rod’s top quality. And, they’re 100% recyclable, meeting RoHS standards, which our eco-friendly clients totally appreciate.

What makes our high purity CuNi rods stand out is their workability and affordability. Available in sizes from 0.1mm wires to thicker bars, they’re easy to customize for your project. The bright, annealed finish means smooth fabrication, and our team can tailor forms or sizes to fit your needs. We’re also tinkering in our R&D lab, fine-tuning alloys for better conductivity or durability in applications like smart home devices or low-power electronics.

These rods aren’t built for heavy-duty jobs. If you need higher temps or tougher corrosion resistance, CuNi10 or CuNi44 might be better. But for low-temp, cost-sensitive projects, our CuNi2 rods with 80-120 HV hardness are hard to beat. Their non-magnetic properties and high ductility make them a favorite for precision, light-duty work.

Our high purity CuNi alloy rods are more than just metal—they’re affordable, reliable solutions for businesses crafting the next wave of consumer and industrial products. We’re pumped to produce these rods and help our clients keep things running smoothly, from cozy homes to high-tech gadgets.

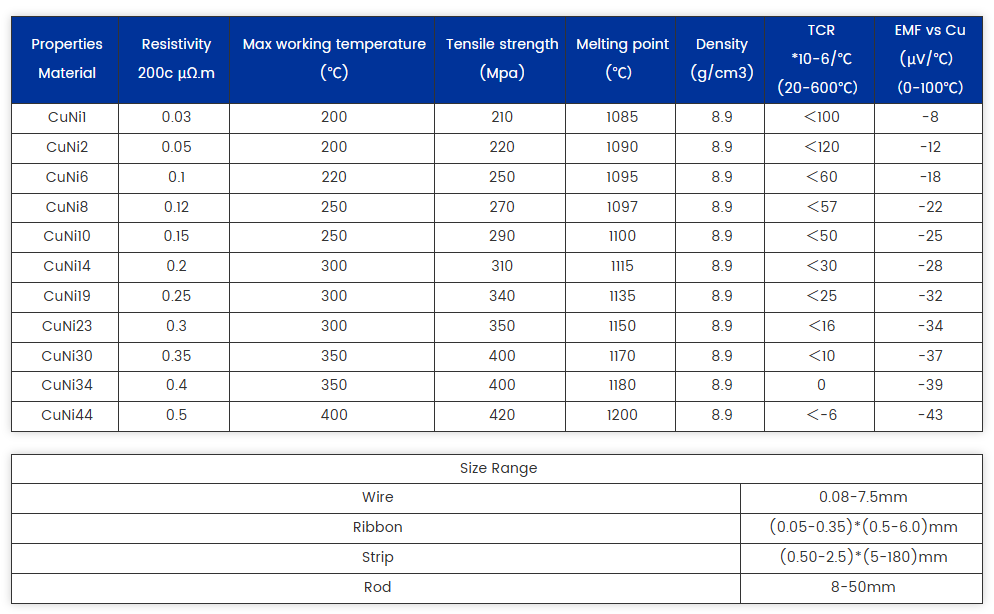

Specification

For more details, pls directly contact us.

Product Description:

The hardness of CuNi Alloy ranges from 80-120 HV, which makes it ideal for applications that require high strength and durability. This Copper Based Alloy is available in both hard and soft conditions, which allows it to be used in a wide range of applications. The hardness can be adjusted based on the specific needs of the application.

Another important attribute of CuNi Alloy is its high purity. It is a Copper Bronze Alloy that is composed of at least 90% Copper, which ensures that it has excellent electrical conductivity. This makes it ideal for use in applications where high electrical conductivity is required.

CuNi Alloy has a resistivity of 0.5, which makes it an ideal material for use in electrical and electronic applications. This Copper Based Alloy is also known for its excellent thermal conductivity, which makes it ideal for use in applications where heat needs to be transferred efficiently.

The maximum temperature that CuNi Alloy can withstand is 200℃, which makes it suitable for use in high-temperature applications. This Copper Bronze Alloy is also known for its excellent resistance to corrosion, which makes it ideal for use in harsh environments.

Overall, CuNi Alloy is a versatile Copper Based Alloy that is widely used in various industrial applications. Its high purity, excellent corrosion resistance, and good thermal conductivity make it an ideal material for use in electrical and electronic applications, as well as in applications where high strength and durability are required.

Features:

Product Name: CuNi Alloy

Thermal Expansion Coefficient: 16.5 X 10^-6/K

Surface: Bright

Tensile Strength: 400-600 MPa

Application: Industry

Resistivity: 0.5

Related Keywords: Aluminium Copper Alloy, Copper Bronze Alloy, Copper Based Alloys

Applications:

The DLX CuNi Alloy is widely used in various industries for different product application occasions and scenarios due to its exceptional properties. Some of the common application fields are mentioned below:

The DLX CuNi Alloy is used as a raw material in the manufacturing of aluminium copper alloy, which is used in the aerospace industry for its high strength and resistance to corrosion. The alloy is used to produce engine parts, landing gear, and other critical components that require high strength and durability.

The DLX CuNi Alloy is also widely used in the copper powder metallurgy industry. The alloy is used to manufacture various powder metallurgy products such as gears, bearings, and sintered filters. The excellent corrosion resistance of the alloy makes it an ideal choice for these types of products.

The DLX CuNi Alloy is extensively used in the automotive industry for the production of various components such as brake lines, fuel systems, and hydraulic systems. The alloy's corrosion resistance and thermal expansion coefficient make it an ideal choice for these applications.

The DLX CuNi Alloy is also used in the marine industry, where its excellent corrosion resistance is critical. The alloy is used to manufacture various marine components such as heat exchangers, condensers, and piping systems.

The DLX CuNi Alloy has a maximum temperature of 200℃, making it suitable for a wide range of applications. Its exceptional properties make it a highly sought-after product in various industries.

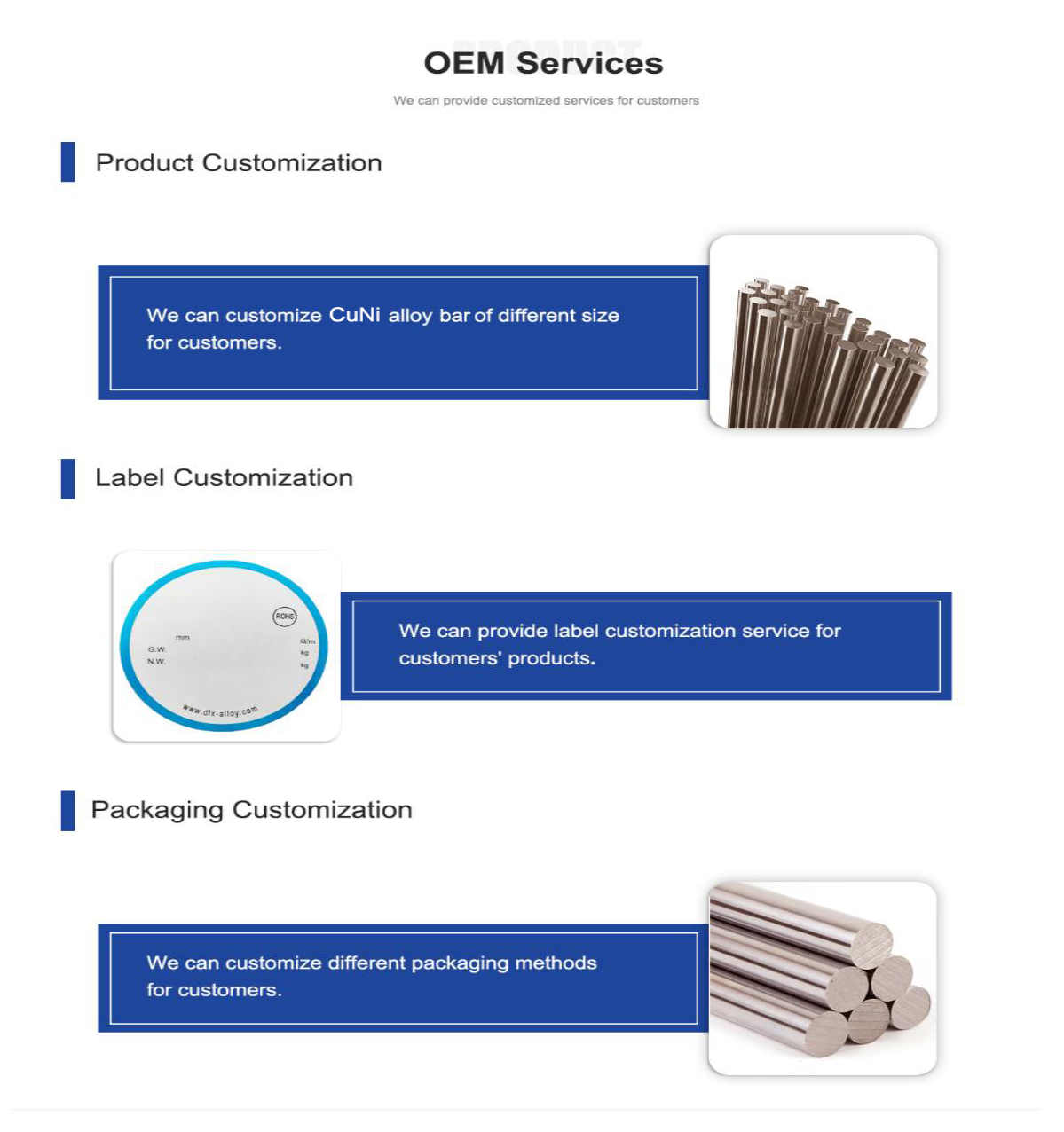

Customization:

Looking to customize your DLX CuNi Alloy product? Look no further! Our product customization services offer a range of options to tailor your Aluminium Copper Alloy or Copper Nickel Alloy to your specific needs.

Our CuNi Alloy product comes from China and has a hardness range of 80-120 HV, a density of 8.94 G/cm3, and a tensile strength of 400-600 MPa. It is available in both hard and soft conditions and has a bright surface.

Whether you need to adjust the hardness level, alter the surface finish, or modify any other aspect of the Alloy Steel Metal, we have the expertise and capabilities to help you achieve your desired outcome. Contact us today to learn more about our product customization services.

Support and Services:

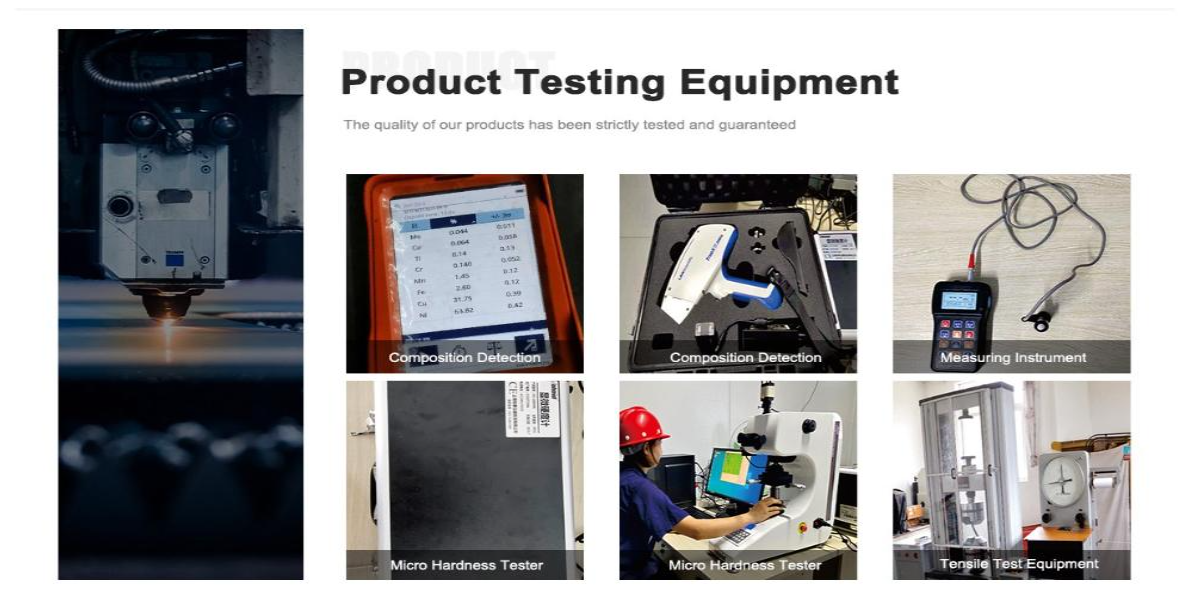

The CuNi alloy is a versatile material used in a wide range of industries. Our technical support team is available to assist with any questions regarding the properties and applications of the CuNi alloy. We can provide guidance on material selection, manufacturing processes, and troubleshooting. Our services include:

Material testing and analysis

Custom alloy development

Product design consultation

On-site support and training

Quality control and assurance

Our goal is to ensure the successful integration of the CuNi alloy into your products and processes. Contact us to learn more about our technical support and services.

Packing and Shipping:

Product Packaging:

The CuNi Alloy product is packaged in a sturdy cardboard box with cushioning material to ensure safe delivery. Each box contains 10 pieces of the alloy product wrapped in plastic to prevent any scratches during transportation.

Shipping:

We ship our CuNi Alloy product worldwide through reliable shipping companies. Depending on your location, shipping times may vary. Please allow 3-5 business days for processing and handling before your order is shipped. Once shipped, you will receive a tracking number to track your package's delivery status.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What are these high purity CuNi alloy rods used for?

They’re ideal for low-temperature heating cables, electrical connectors, and light-duty resistors.

How corrosion-resistant are these rods?

They’re great at resisting moisture, mild chemicals, and atmospheric corrosion.

What’s the max temperature these rods can handle?

They’re good up to 200°C, perfect for low-heat applications.

Are these rods magnetic?

No, they’re non-magnetic, suitable for sensitive electronics.

Can these rods be welded or soldered?

Yep, they’re super easy to weld and solder for quick fabrication.

Which industries use these rods?

Electronics, automotive, HVAC, and consumer goods are the main ones.

How do these rods compare to other CuNi alloys?

With low nickel content, they’re cheaper than CuNi10 or CuNi44 but limited to lower temps.

Are these rods eco-friendly?

They’re fully recyclable and meet standards like RoHS.

-

Wholesale Price Copper Nickel Alloy CuNi8 CuNi 10 Round Rod Bar

Enquire Now -

Good Price Nickel Alloy CuNi8 CuNi10 Round & Square Bar For Sale

Enquire Now -

CuNi2 Bar CuNi Alloy Various CuNi Models CuNi2 CuNi6 Bar/ CuNi44 Rod

Enquire Now -

High Quality Customized CuNi Super Alloy Factory Direct Supply Super Bar CuNi8

Enquire Now