Sale Shinny Copper Nickel 24mm Rod Cuni14

- Product Details

We’re pumped to showcase our shiny 24mm CuNi 14 rods, a copper-nickel alloy that’s a real game-changer for a ton of industries. CuNi14, with its 14% nickel content, strikes a sweet balance—solid performance, great corrosion resistance, and a price tag that won’t make you wince. Let’s dive into why this alloy is such a big deal for us and our clients.

CuNi14 is our star player for applications that need a bit more muscle than low-nickel alloys like CuNi2. We’re talking heating elements in industrial furnaces, electrical connectors in EVs, and fittings on ships that face brutal saltwater conditions. Its electrical conductivity is just right for resistive heating, and it holds up like a champ at temperatures up to 350°C.

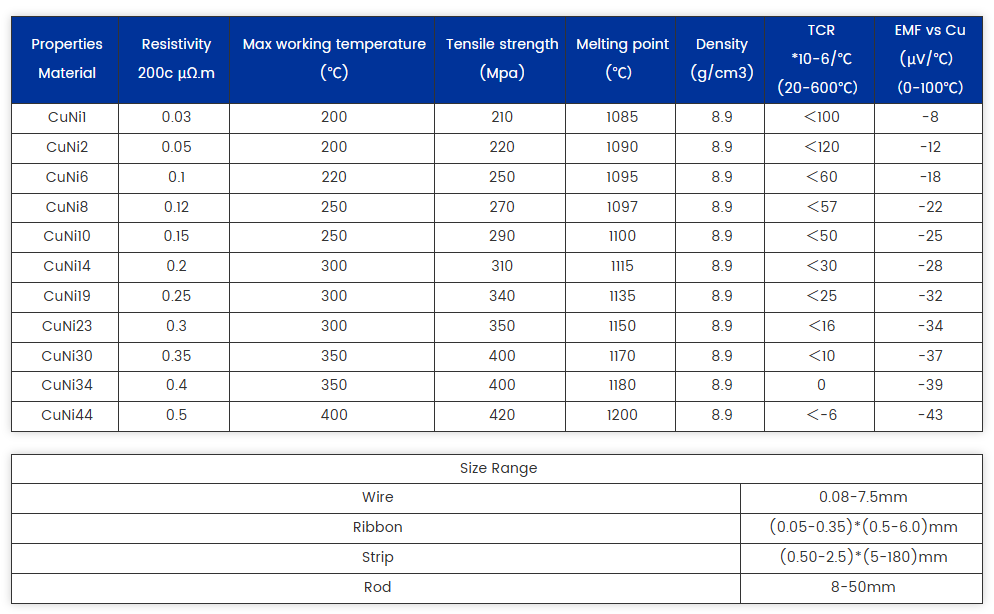

CuNi Series

Changzhou DLX alloy is a factory for nickel copper resistance alloy products. And We could offer CuNi14 in wire, rod, strip and flat wire.CuNi14 resistance alloy is a kind of copper nickel binary alloy, which has low temperature coefficient of resistance. It is used to make rheostat, shunt, controller and other low voltage electrical components with a maximum operating temperature of 300°C. For its good heat coefficient, this alloy is also widely used in low temperature heating cables of automobile heating cushion, railway snow melting and so on

Copper nickel alloy has low electric resisitance, good heat-resistant and corrosion-resistant, easy to be processed and lead welded. It is used to make the key components in the thermal overload relay, low resistance thermal circuit breaker, and the electrical appliances. It is also an important material for electrical heating cable.

For more details, pls directly contact us.

Properties:

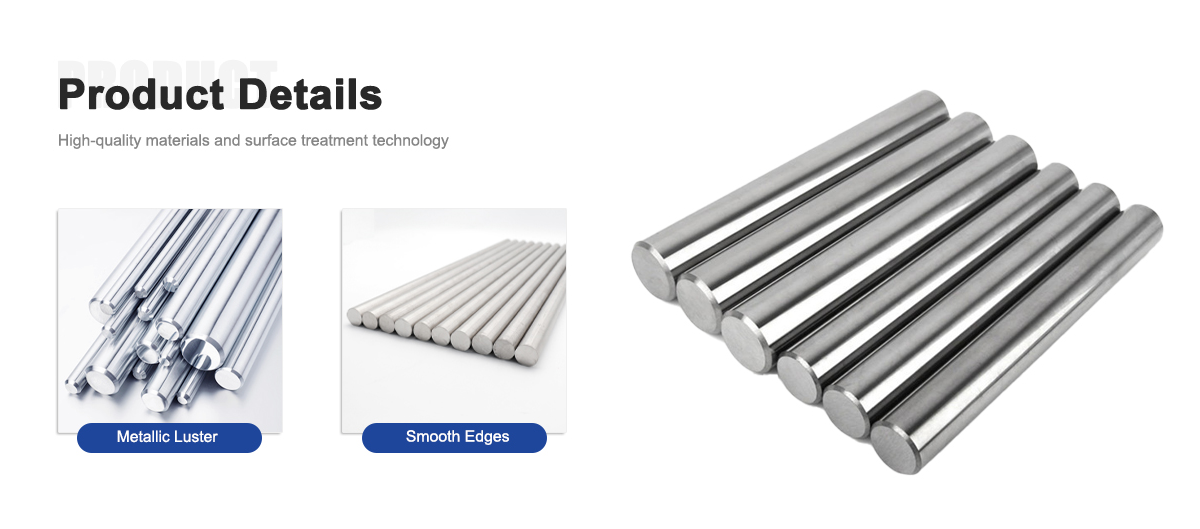

Aesthetic Appeal:

The shiny surface finish provides an attractive, polished appearance, making it suitable for decorative applications.

The bright, silvery look is maintained over time due to the corrosion resistance of the alloy.

Corrosion Resistance:

Excellent resistance to corrosion, particularly in marine and industrial environments. This makes the alloy durable and long-lasting.

Resistant to biofouling and seawater corrosion.

Mechanical Strength:

Good mechanical strength, which can be further enhanced through work hardening.

Provides durability and robustness in structural applications.

Thermal and Electrical Conductivity:

Maintains good thermal and electrical conductivity, making it useful in electrical and heat-exchanging applications.

While not as conductive as pure copper, it offers a good balance of conductivity and strength.

Non-Magnetic:

Non-magnetic properties, making it suitable for applications where magnetic interference needs to be minimized.

Workability and Ductility:

Highly ductile and can be easily formed into various shapes, including rods, wires, and sheets.

The shiny finish can be achieved through processes like polishing and electroplating.

Applications:

Decorative Items:

Used in the production of coins, medals, and various ornamental items due to its attractive appearance and durability.

Employed in architectural elements such as door handles, railings, and fixtures.

Marine Applications:

Ideal for marine hardware, such as boat fittings and components, because of its resistance to seawater and its polished look.

Used in shipbuilding for aesthetic and functional purposes.

Electrical Components:

Used in electrical connectors, terminals, and switchgear due to its good conductivity and non-magnetic properties.

Suitable for precision resistors and other components where stable resistance is needed.

Automotive and Aerospace:

Employed in automotive trim and decorative elements.

Used in aerospace for components that need to combine strength, durability, and a polished appearance.

Medical and Laboratory Equipment:

Used in medical instruments and laboratory equipment due to its corrosion resistance and ease of sterilization.

Industrial Equipment:

Utilized in various industrial applications, including valves, pumps, and fittings, where both functionality and appearance are important.

Maintenance of Shine:

To maintain the shiny finish, regular cleaning and occasional polishing may be required, especially in harsh environments.

Protective coatings can be applied to preserve the brightness and prevent tarnishing.

About Us:

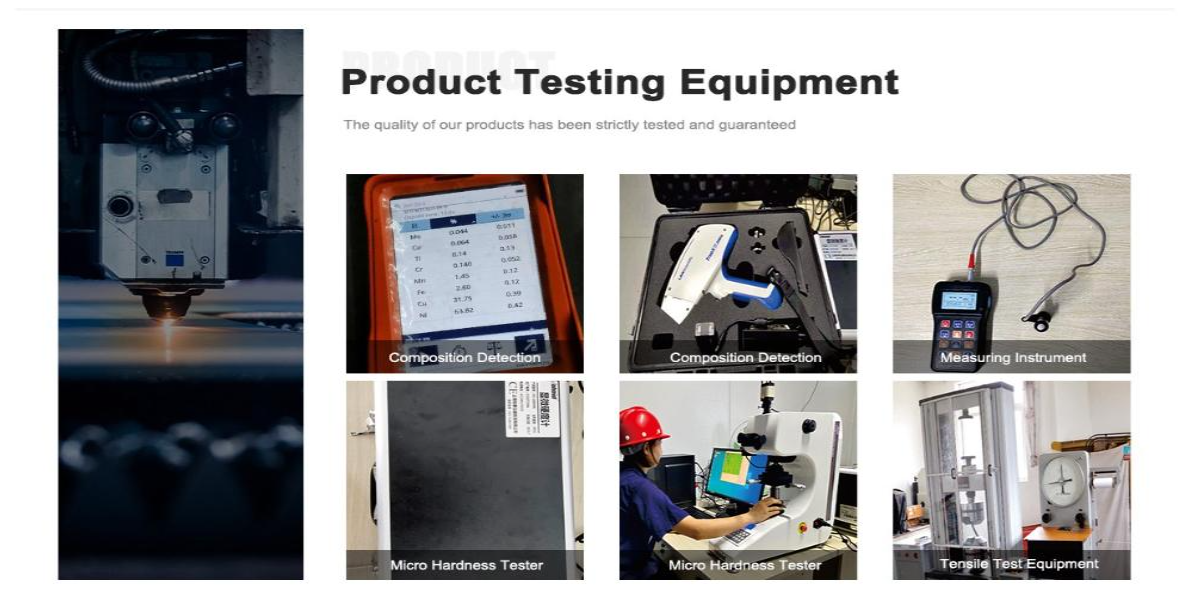

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What's CuNi14 used for?

It's popular in heating elements, marine fittings, and electrical connectors.

How does CuNi14 hold up against corrosion?

It's very resistant, especially to seawater, making it great for marine applications.

What's the max temperature CuNi14 can handle?

It's good up to 350°C, depending on the application.

Is CuNi14 magnetic?

Nope, it's non-magnetic, perfect for sensitive electronics.

Can you weld or solder CuNi14?

Absolutely, it's easy to weld or solder, which simplifies fabrication.

Which industries use CuNi14 rods?

Marine, automotive, electrical, and renewable energy sectors are the main ones.

How does CuNi14 stack up against other alloys?

With 14% nickel, it's pricier than CuNi2 but offers better strength and temperature resistance, though less than CuNi44.

Is CuNi14 eco-friendly?

Yes, it's recyclable and meets environmental standards like RoHS.

-

Wholesale Price Copper Nickel Alloy CuNi8 CuNi 10 Round Rod Bar

Enquire Now -

Good Price Nickel Alloy CuNi8 CuNi10 Round & Square Bar For Sale

Enquire Now -

CuNi2 Bar CuNi Alloy Various CuNi Models CuNi2 CuNi6 Bar/ CuNi44 Rod

Enquire Now -

High Quality Customized CuNi Super Alloy Factory Direct Supply Super Bar CuNi8

Enquire Now