Marine Grade Copper Nickel Busbar - Low Resistance

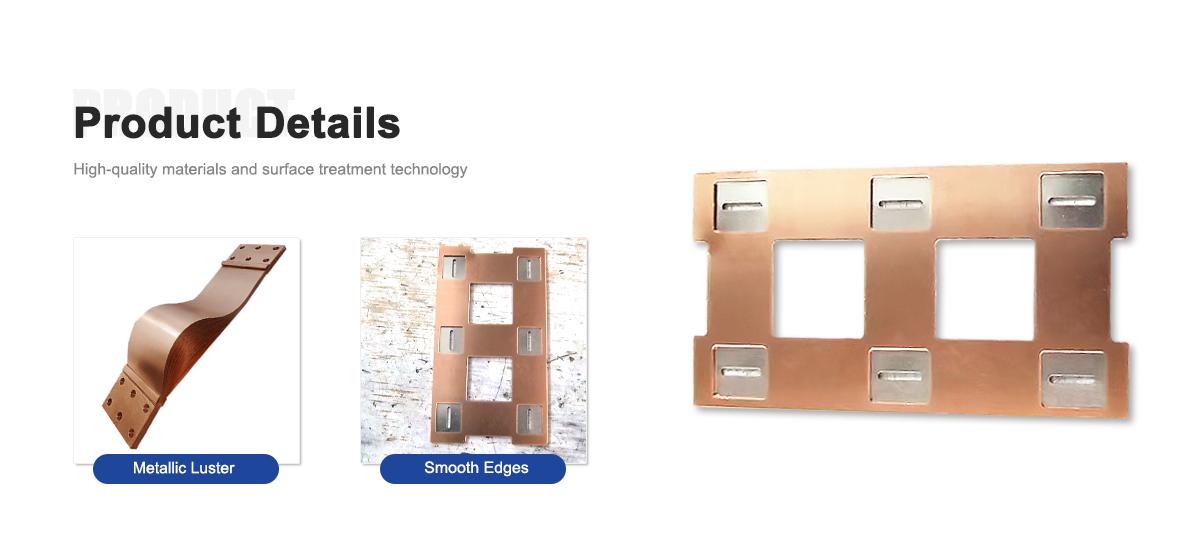

- Product Details

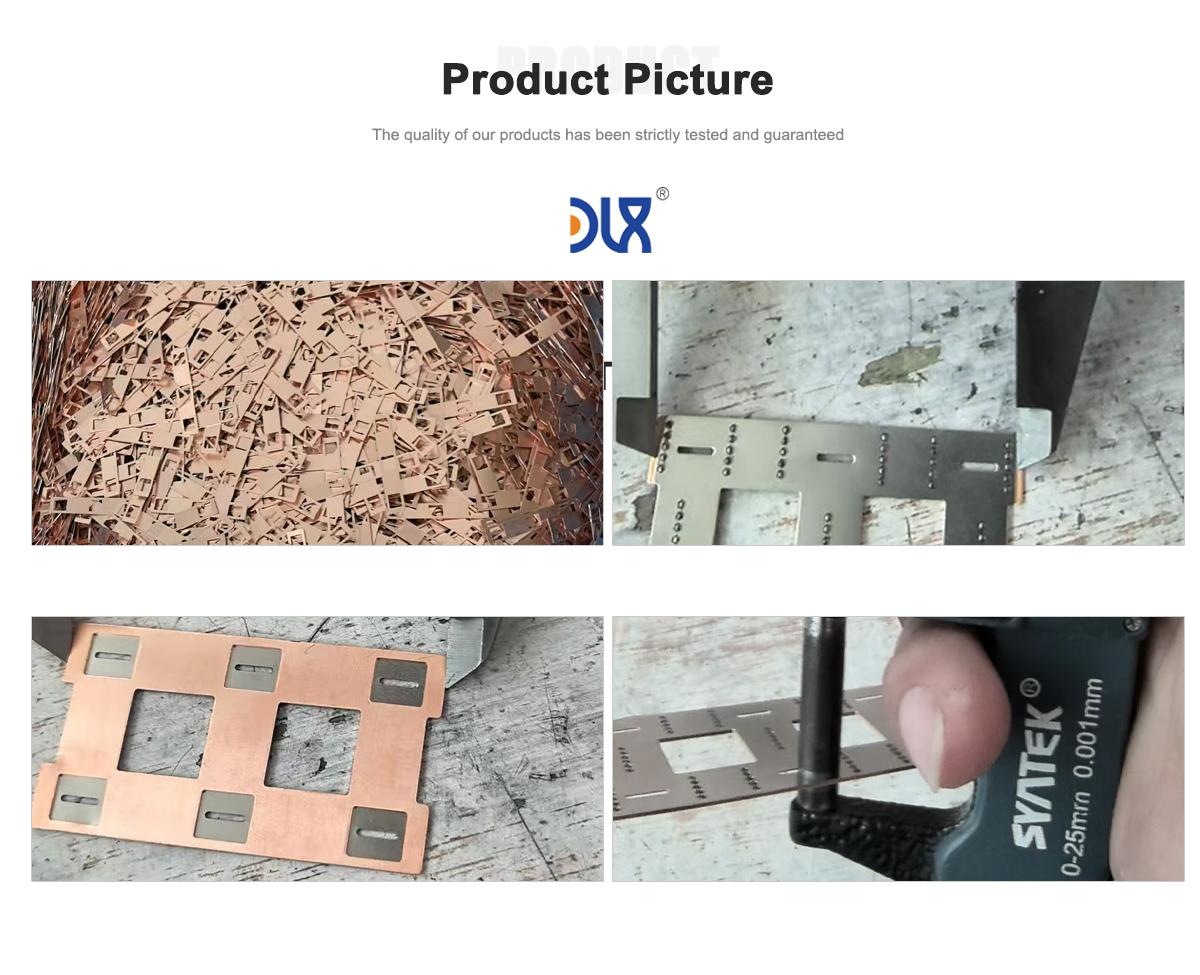

Products Description

What is Marine Grade Copper Nickel Busbar?

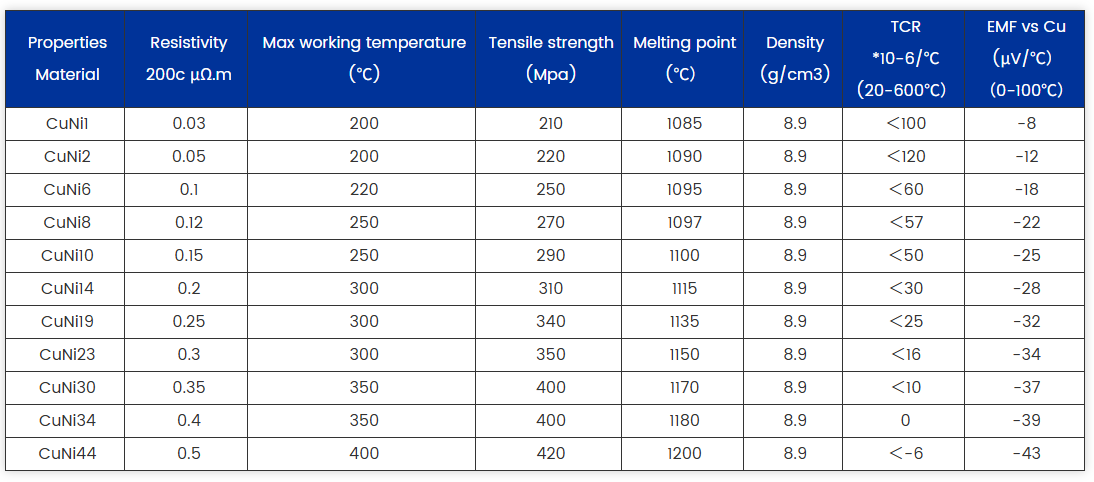

Copper Nickel Busbar is a high-performance composite conductor engineered for marine and corrosive environments. Composed primarily of copper with 10-30% nickel alloying, it leverages the inherent properties of copper nickel alloys for exceptional seawater corrosion resistance and low electrical resistance.

The Marine Grade Copper Nickel Busbar features a nickel-plated surface that enhances durability while maintaining low resistance for efficient power distribution. Small alloy variations significantly influence its mechanical and electrical properties, making it ideal for demanding applications.

Our Copper Nickel Busbar meets stringent standards like ASTM B187 for copper bus bars and industry-specific marine corrosion tests, guaranteeing high purity and reliability. This Low Resistance Copper Nickel Busbar is perfect for marine power systems, offshore platforms, and electrical distribution requiring flexibility, strength, and biocompatibility-like resistance in saltwater.

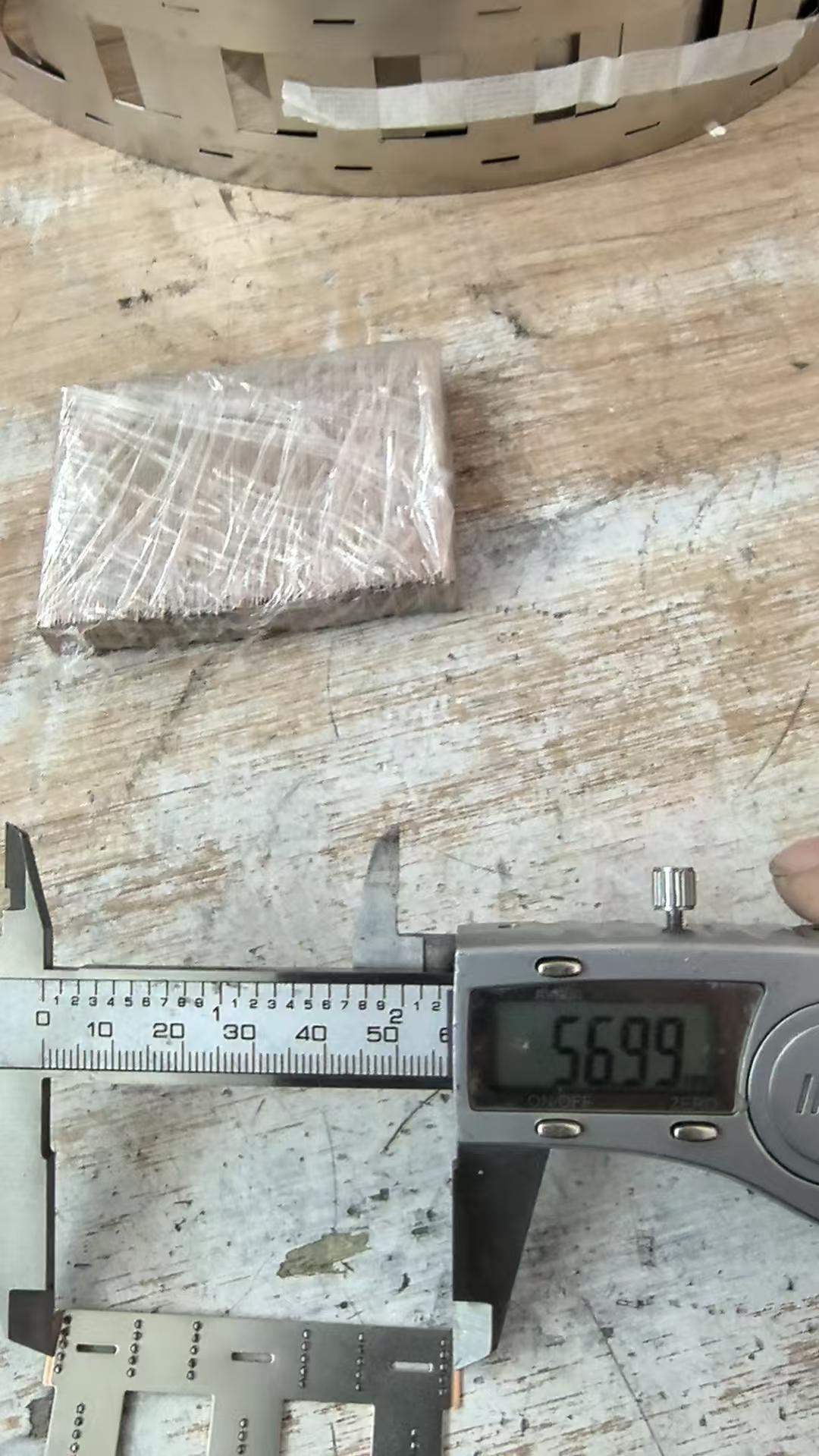

Products Specification

Key Features

1. Exceptional Corrosion Resistance

Resists degradation in seawater, acidic, and alkaline conditions, making the Copper Nickel Busbar perfect for marine environments.

2. High Electrical Conductivity

Offers reliable conductivity (up to 20% IACS for CuNi 90/10), balancing performance with durability in CuNi alloy busbars.

3. Low Electrical Resistance

Offers superior conductivity with minimal voltage drop, ideal for high-current marine power transmission.

4. Enhanced Mechanical Strength

Provides good tensile strength (up to 400 MPa) and ductility, ideal for structural integrity in high-conductivity CuNi alloy systems.

5. Customizable Dimensions

Available in various sizes with polished or mill finishes, tailored for marine Copper Nickel Busbar needs.

6. Thermal Stability

Maintains properties at elevated temperatures, ensuring long-term reliability in heat exchanger-integrated power setups.

Products Applications

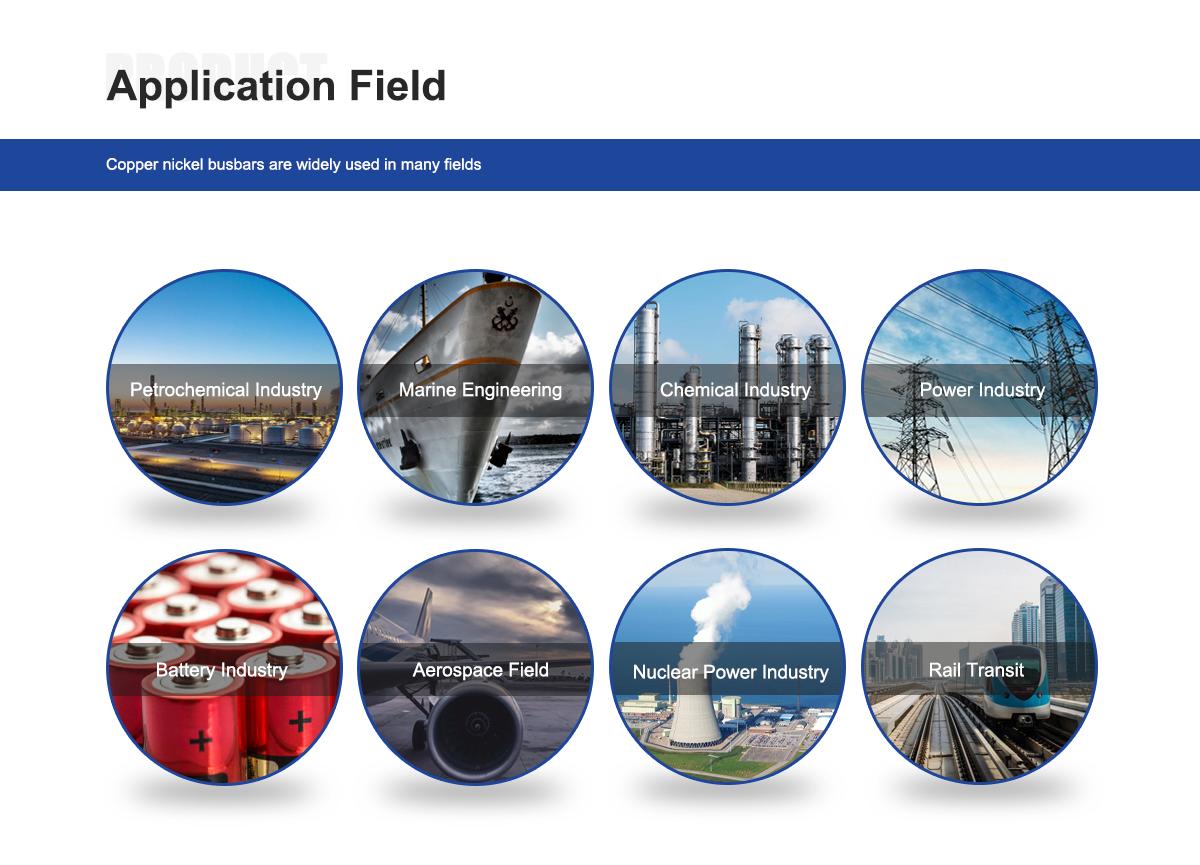

With its unmatched combination of low resistance, corrosion resistance, and mechanical robustness, the Marine Grade Copper Nickel Busbar is indispensable in:

(1) Marine and Offshore Power Systems

Utilized in shipboard electrical distribution, desalination plants, and offshore platforms for reliable, low-loss power transmission in saltwater environments.

(2) Naval and Commercial Shipping

Employed in propulsion systems, lighting, and control panels due to biofouling resistance and high conductivity.

(3) Renewable Energy Installations

Ideal for tidal and wave energy converters, where Copper Nickel Busbar withstands constant submersion and harsh weather.

(4) Chemical and Industrial Processing

Applied in corrosive fluid handling equipment and power bus systems for its durability and low resistance.

(5) Aerospace and Defense

Used in marine-adjacent applications like coastal radar systems for vibration resistance and electrical efficiency.

About Us

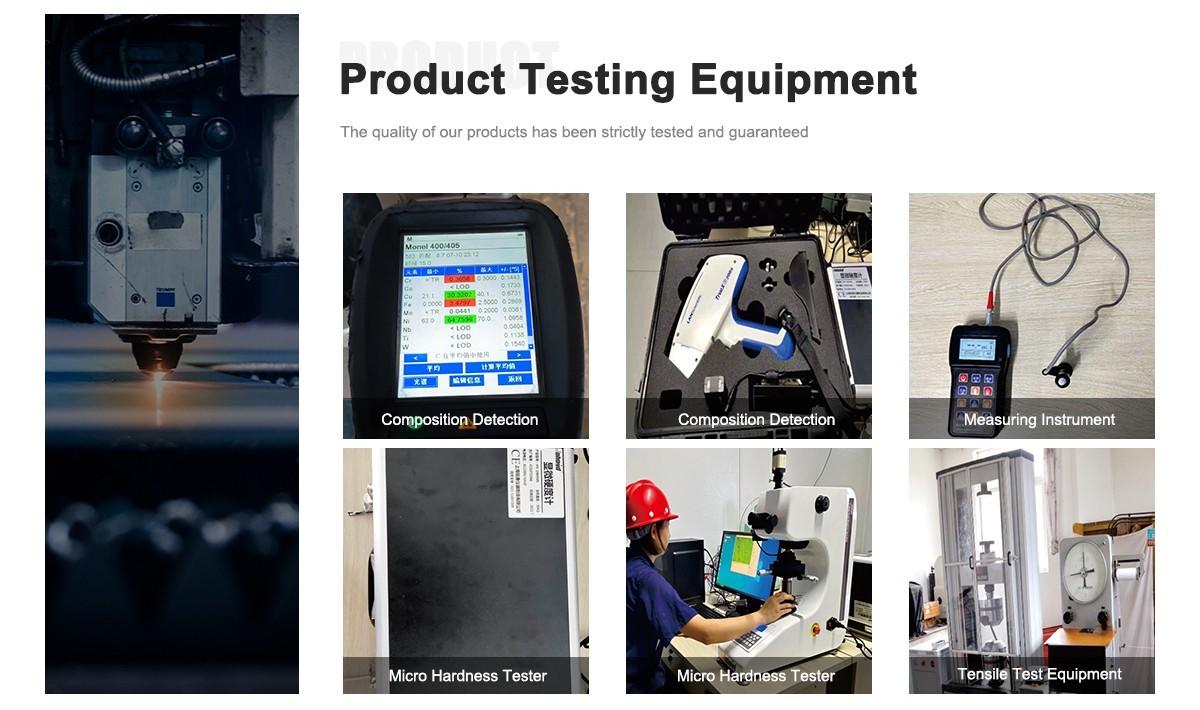

CHANGZHOU DLX ALLOY CO, LTD was established in 2002. Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy , NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

FAQs:

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.