Premium Copper Nickel Busbar with High Thermal Conductivity

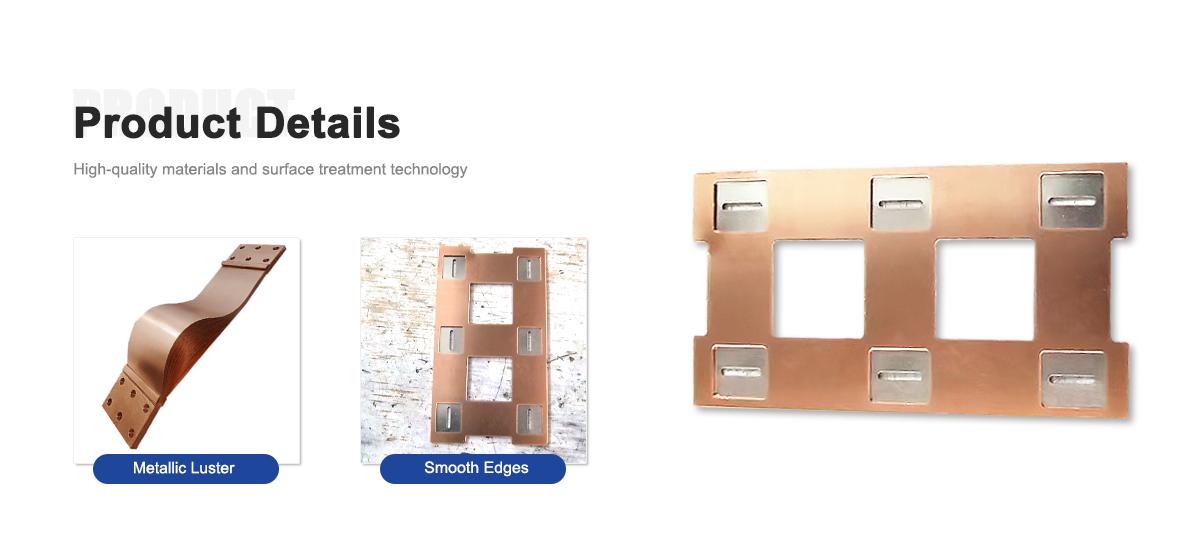

- Product Details

Products Description

What is Copper Nickel Busbar?

Copper nickel busbar is a high-performance electrical conductor formed by bonding a layer of nickel to a copper core, creating a robust composite material. This copper nickel busbar leverages the excellent electrical and thermal conductivity of copper (up to 98% IACS) while incorporating nickel's superior corrosion resistance and mechanical strength.

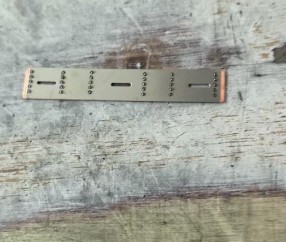

The nickel layer, typically 1-20 µm thick, provides a protective barrier against oxidation and wear, ensuring the copper nickel busbar maintains its high thermal conductivity over extended service life. This makes our premium copper nickel busbar a preferred choice for industries requiring reliable, low-maintenance solutions.

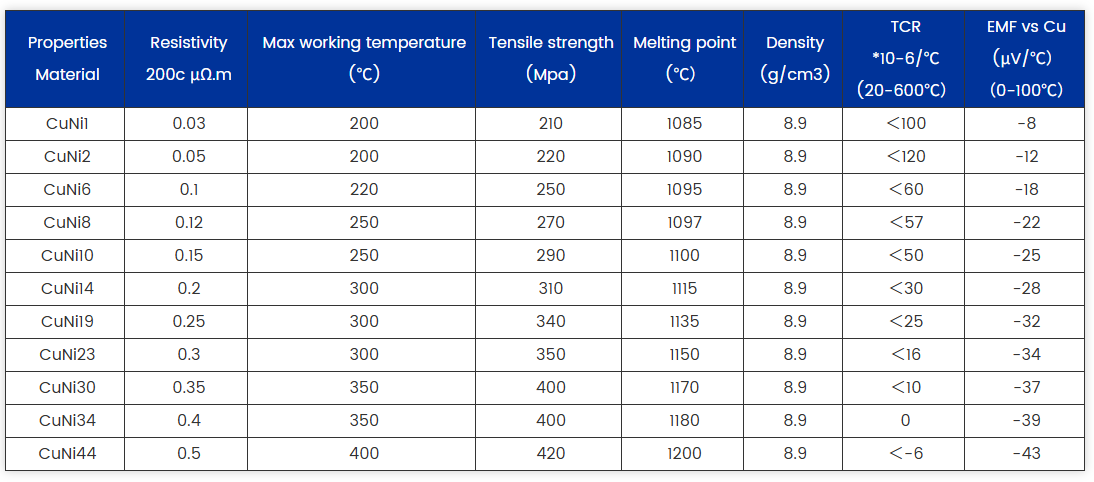

Products Specification

Why Choose Copper Nickel Busbar?

Choosing a premium copper nickel busbar offers unmatched advantages in performance and longevity. Unlike standard copper busbars that are prone to oxidation in humid or corrosive environments, the copper nickel busbar's nickel layer acts as a robust shield, preventing degradation and ensuring consistent high thermal conductivity even under prolonged exposure to saltwater, chemicals, or high humidity. This results in up to 50% longer service life compared to uncoated alternatives, reducing maintenance costs and downtime.

Additionally, the copper nickel busbar provides superior solderability and contact stability, minimizing electrical resistance and heat buildup in high-current applications—critical for energy efficiency in power grids and EV battery packs. Its lightweight yet mechanically strong design supports easier installation and supports sustainability goals by enabling recyclable, eco-friendly systems. For industries demanding reliability without compromise, the copper nickel busbar delivers optimal balance of conductivity, durability, and cost-effectiveness, making it the smart choice for future-proof electrical infrastructure.

Key Features

1. Exceptional High Thermal Conductivity

Delivers superior heat dissipation, minimizing energy loss in power systems.

2. Superior Corrosion Resistance

Nickel plating withstands harsh environments like marine and chemical settings, extending lifespan.

3. High Electrical Conductivity

Copper core ensures efficient current flow with minimal resistance, ideal for high-current applications.

4. Enhanced Mechanical Durability

Resists wear, abrasion, and mechanical stress for reliable performance in dynamic setups.

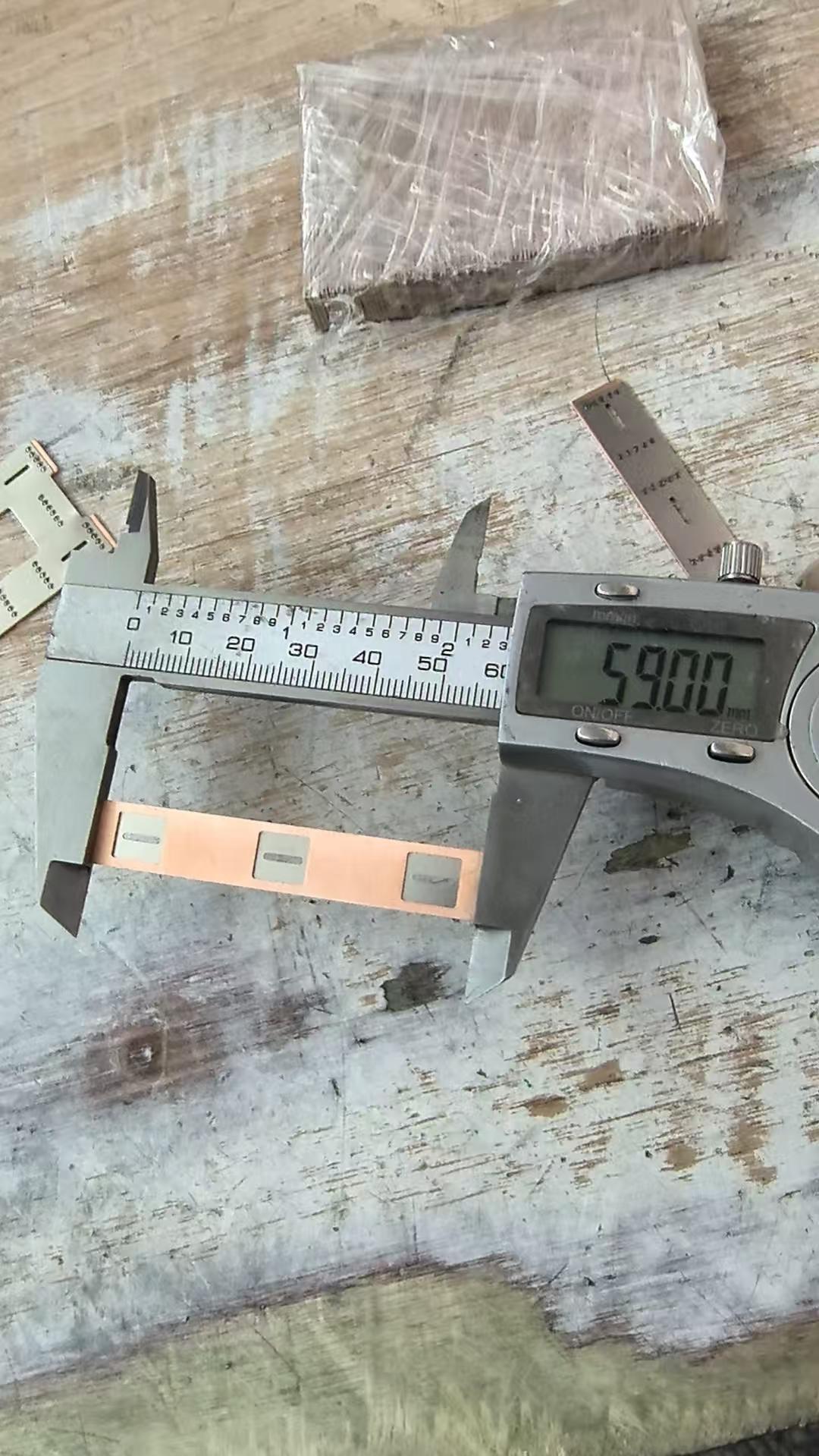

5. Customizable Dimensions

Offered in various sizes and finishes, including nickel-plated or clad, to meet specific project needs.

6. Temperature Resilience

Handles up to 300°C without degradation, suitable for high-heat industrial uses.

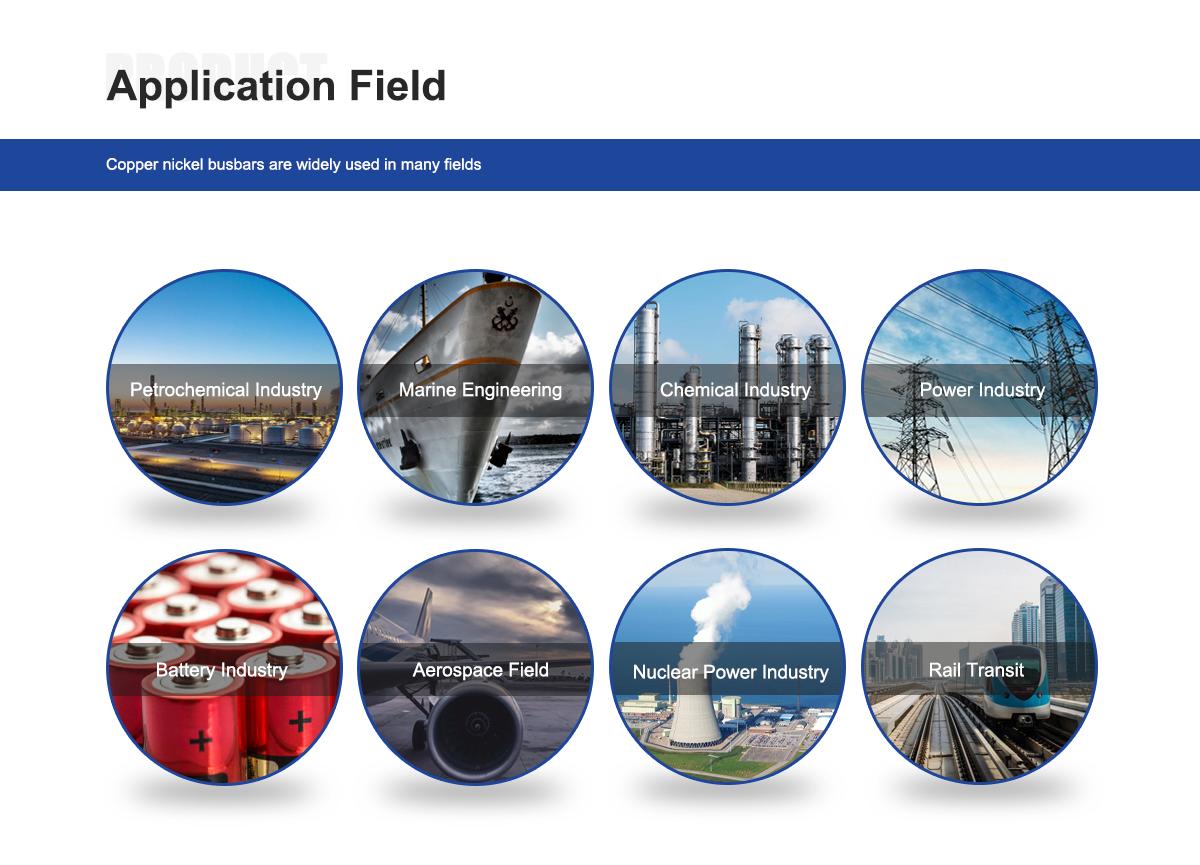

Products Applications

Harnessing its high conductivity, corrosion resistance, and biofouling deterrence, the Copper Nickel Busbar is essential in:

(1) Marine Applications

Utilized in shipboard power distribution, desalination plants, and offshore platforms for reliable Copper Nickel Busbar performance in seawater-exposed systems.

(2) Electrical Systems

Employed in high-conductivity busbar setups for marine vessels, ensuring efficient power transfer with CuNi alloy durability.

(3) Offshore and Chemical Processing

Ideal for busbars in corrosive environments like oil rigs and chemical plants, where Copper Nickel Busbar resists erosion and maintains conductivity.

(4) HVAC and Power Generation

Applied in heat exchangers and generators for its thermal stability and high electrical conductivity in CuNi alloy form.

(5) Industrial Power Distribution

Used in automation and robotics for precision components, leveraging the marine-grade resilience of Copper Nickel Busbar.

About Us

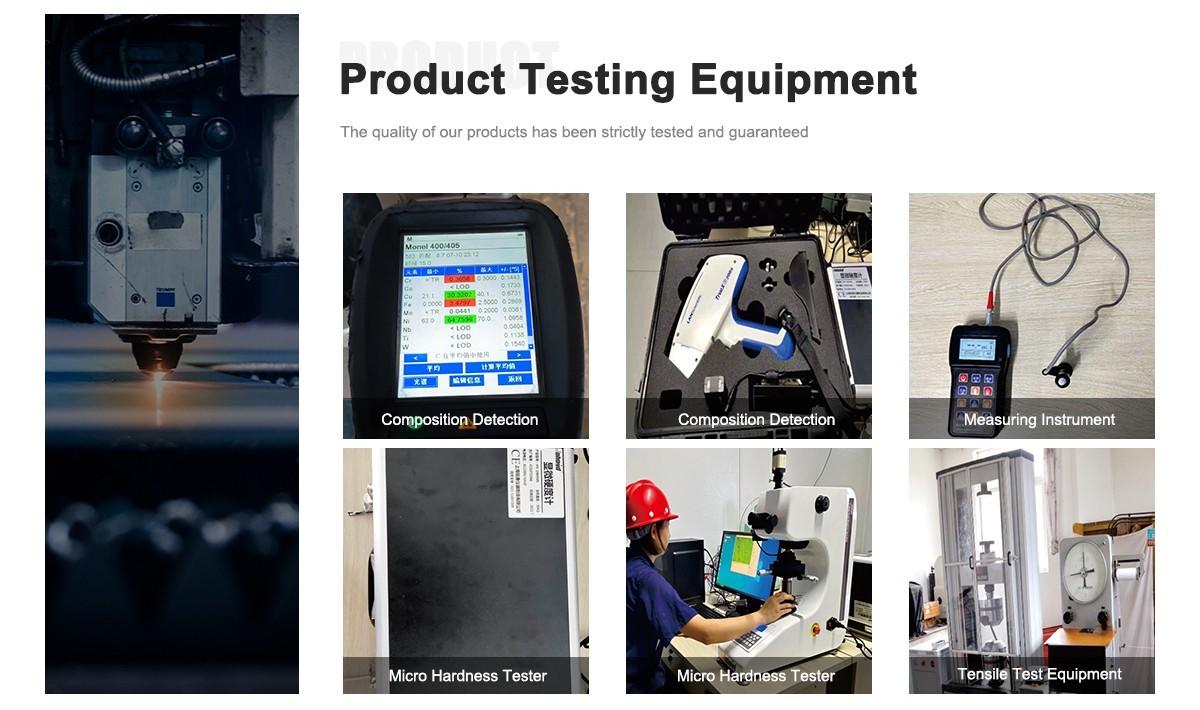

CHANGZHOU DLX ALLOY CO, LTD was established in 2002. Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy , NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

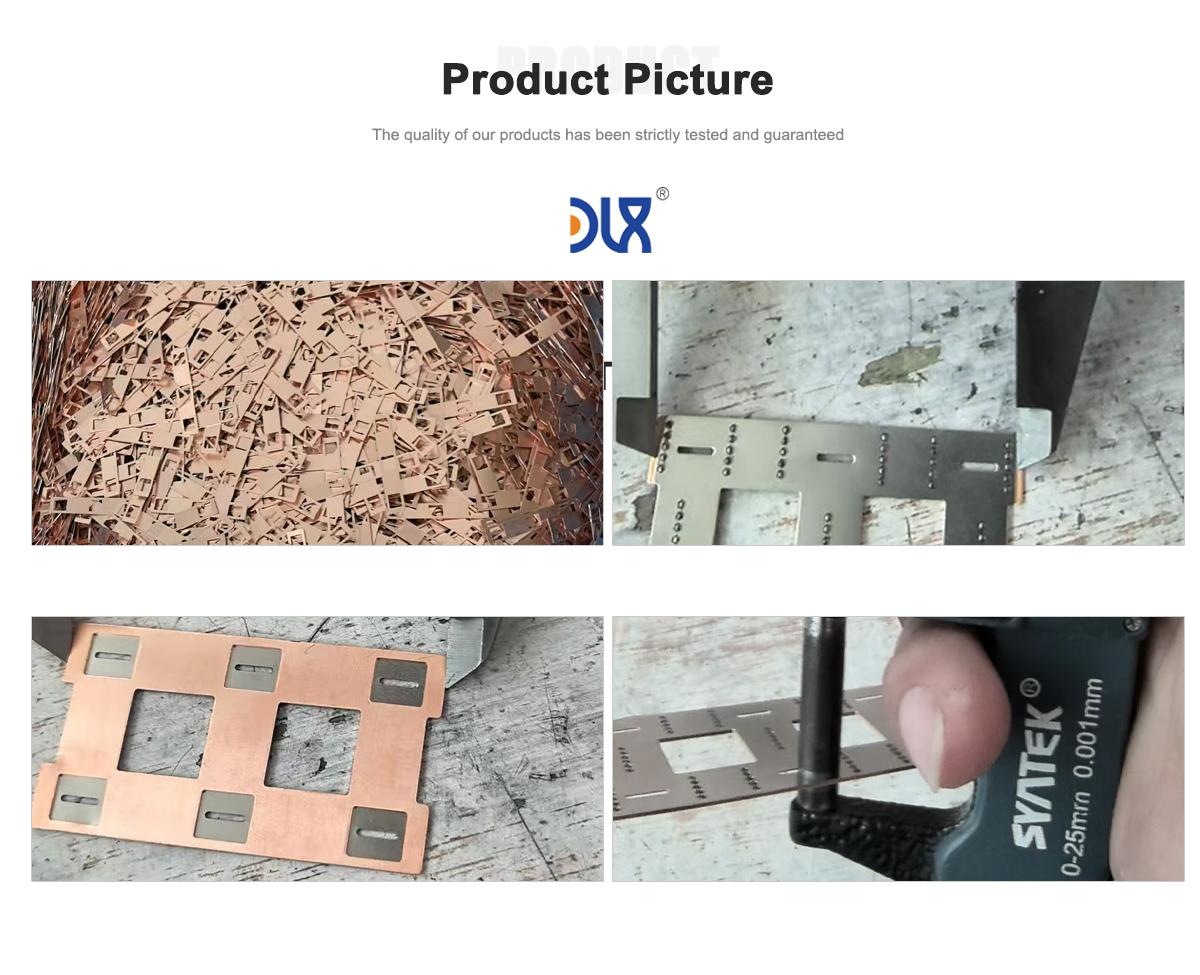

We support all kinds of testing:

FAQs

FAQs:

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.

-

Industrial Copper Nickel Busbar - Low Maintenance & High Efficiency

Enquire Now -

Corrosion-Resistant Copper Nickel Bus Bar for Power Systems

Enquire Now -

Competitive Pricing Copper Nickel Busbar for Battery Connection

Enquire Now -

Custom Copper Nickel Busbar for Harsh Environments - Offshore, Desalination Plants

Enquire Now