0Cr27Al7Mo Heating Resistance Wire (2.0mm Diameter) – Specifications

- Product Details

Specifications for 0Cr27Al7Mo2 FeCrAl Heating Resistance Wire (2.0mm Diameter)

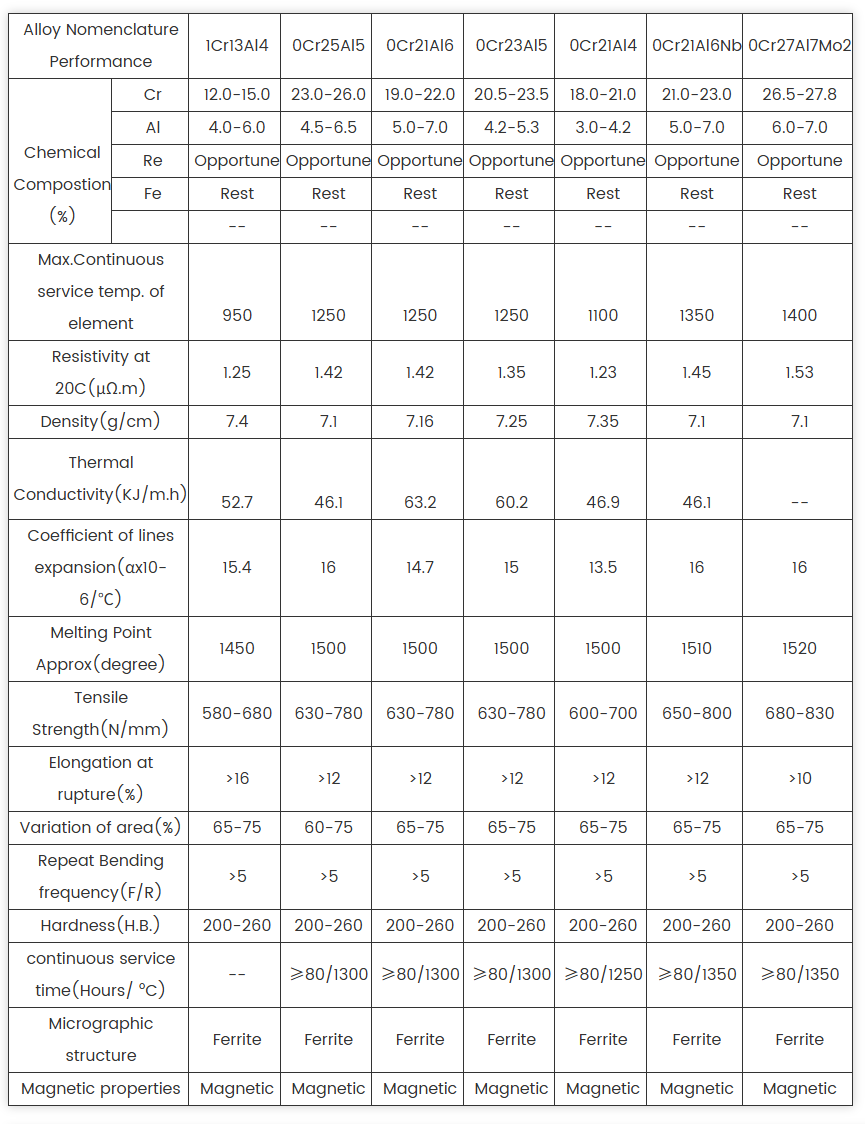

Chemical Composition (%)

Iron (Fe): Balance (~65–66%)

Chromium (Cr): 26.5–27.8

Aluminum (Al): 6.0–7.0

Molybdenum (Mo): 1.8–2.2

Rare Earths: Trace amounts (e.g., La+Ce, Yttrium, Hafnium, Zirconium) to improve oxidation resistance and lifespan

Other Impurities: ≤0.1% (e.g., Si, Mn, C, S, P)

Physical Properties

Density: 7.10 g/cm³

Melting Point: ~1500–1520°C (2732–2768°F)

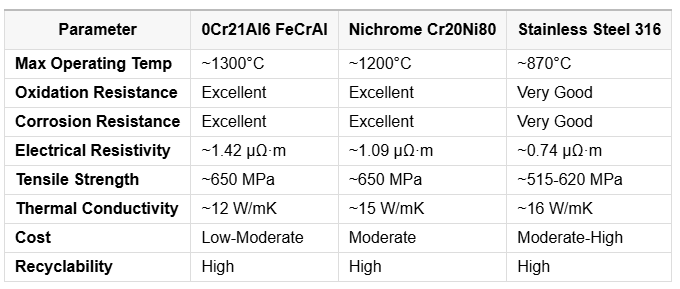

Maximum Continuous Operating Temperature: 1400°C (2550°F)

Resistivity at 20°C: 1.45 ± 0.07 µΩ·m (Ω mm²/m)

Thermal Conductivity: ~11 W/m·K at room temperature

Coefficient of Thermal Expansion: ~15 × 10⁻⁶/K (20–1000°C)

Specific Heat Capacity: ~460 J/kg·K

For more details, pls directly contact us.

Mechanical Properties

Tensile Strength: ~700 MPa at room temperature

Elongation: ≥10% (depending on processing)

Hardness: ~200–260 HB (annealed condition)

Creep Resistance: Enhanced by molybdenum, suitable for prolonged high-temperature stress

Electrical Properties

Resistance per Meter (at 20°C): ~0.46 Ω/m for 2.0mm diameter (calculated using resistivity and cross-sectional area: R = ρL/A, where ρ = 1.45 µΩ·m, A = πr² = 3.14 mm²)

Temperature Coefficient of Resistance: Low, ensuring stable resistance at high temperatures

Resistance Temperature Factor (Ct): Varies with temperature (e.g., ~1.05 at 1000°C, multiply base resistivity by Ct for working temperature)

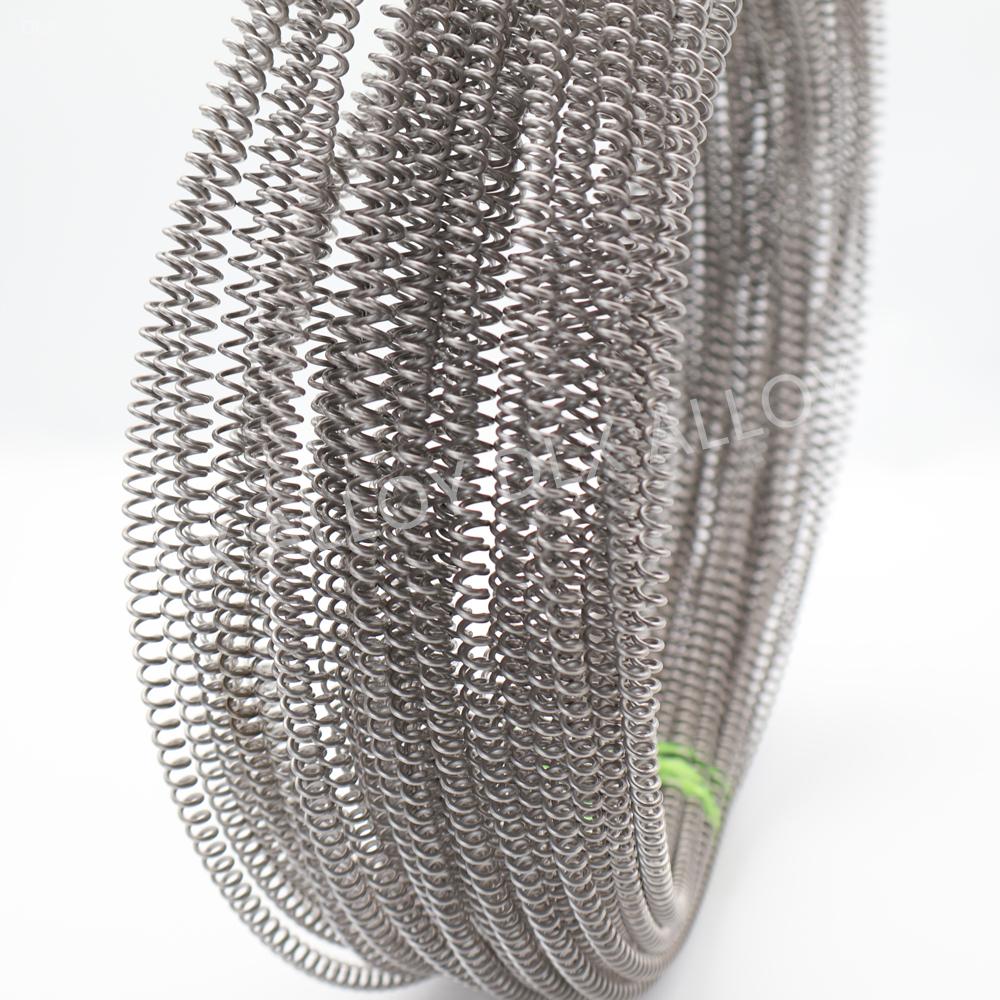

Dimensions and Form

Diameter: 2.0mm (±0.02mm tolerance, typical for precision wire)

Form: Round wire, available in straight lengths, coils, or spools

Surface Finish: Bright annealed or oxidized (oxidized enhances Al2O3 layer for better oxidation resistance)

Packaging: Coils (1–3 kg/roll typical), spools, or custom lengths, packed with plastic film in cartons or wooden cases

Performance Characteristics

Oxidation Resistance: Forms a stable Al2O3 oxide layer above 1000°C, protecting against sulfur-rich, acidic, or oxidative environments

Corrosion Resistance: Excellent under high temperatures, suitable for harsh industrial atmospheres

High-Temperature Stability: Maintains structural integrity up to 1400°C, ideal for single crystal, sintering, ceramic calcining, and diffusion furnaces

Creep Resistance: Molybdenum addition significantly reduces creep under prolonged high-temperature stress, extending service life

Weldability: Moderate, requires care due to high aluminum content; brazing or mechanical joining often preferred.

Typical Applications

Industrial Furnaces: Heating Element s for single crystal furnaces, sintering furnaces, ceramic calcining furnaces, heat treatment furnaces, and diffusion furnaces operating above 1200°C

Electrical Heating Elements: Used in high-temperature industrial equipment, glass top hobs, and quartz tube heaters

Catalytic Converters: Supports high-temperature environments in automotive applications

Resistors: High resistivity suits precision resistor applications

Considerations

Creep at Max Temperatures: Monitor above 1400°C to prevent deformation.

Insulation: Ensure proper electrical insulation (e.g., ceramic supports) for high-voltage applications to prevent short circuits.

Handling: Fine 2.0mm wire requires careful coiling to avoid stress fractures during installation.

Availability: Stocked by suppliers like Tankii and Ualloy, with bulk discounts for wholesale orders.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

-

What is FeCrAl Fiber Felt?

Enquire Now -

0Cr21Al6 FeCrAl Wire Corrosion Resistance Heating Electric Resistance Alloy Wires for Household App

Enquire Now -

Heating Element Wire Resistance Wire FeCrAl Alloy Wire With Superior Quality

Enquire Now -

Customized 0Cr23Al5 AWG44 Wire Heating FeCrAl Stock Wire For Resistor Furnace & Heater

Enquire Now