Premium Silicone Braided Heating Cable For Equipment Warm-up

- Product Details

Products Description

What are silicone braided heating cables?

The Premium Silicone Braided Heating Cable represents a advanced heating solution that combines exceptional thermal performance with mechanical durability. This heating cable features a specialized construction with alloy heating wires encapsulated within multiple layers of protection, including silicone rubber insulation and a protective glass fiber braid.

This construction enables reliable operation in temperatures up to 200°C continuously, with some variants capable of withstanding even higher temperatures for shorter durations. The cable's design ensures rapid heat-up times and excellent temperature uniformity along the entire length, making it ideal for precise thermal management applications.

Why Choose DLX Silicone Braided Heating Cables?

DLX has established itself as a leading provider of advanced heating solutions through decades of specialization in heating technology. Our silicone braided heating cables represent the culmination of this experience, offering:

Proven Reliability: With insulation resistance ≥100MΩ and extensive bending endurance testing, our cables deliver dependable performance year after year.

Customization Capabilities: We offer customized heating cable solutions with various diameter options, resistance values, and length specifications to meet your specific application requirements.

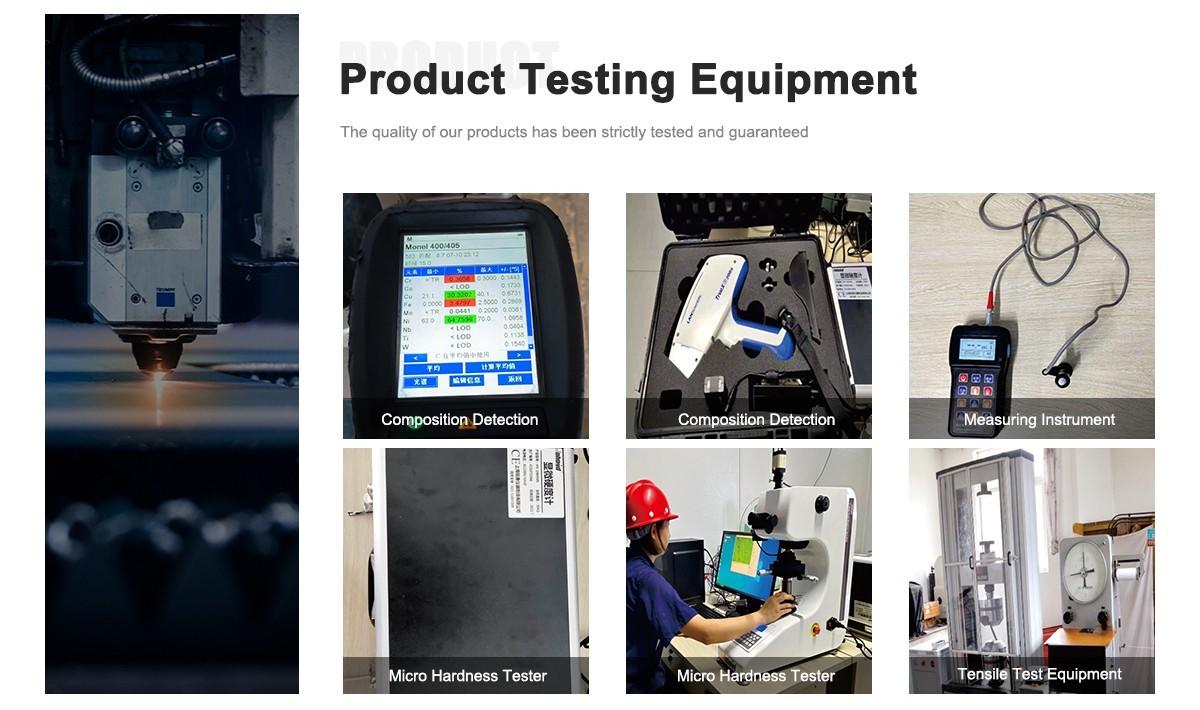

Quality Assurance: All DLX silicone braided heating cables undergo rigorous quality control and testing to ensure they meet our high standards for performance and safety.

Technical Expertise: Our engineering team provides comprehensive support from design through implementation, ensuring optimal heating cable selection and integration for your specific application.

Global Certifications: Our products comply with international standards including UL and RoHS , facilitating their use in projects worldwide.

Key Features

Exceptional Heat Resistance:

Our silicone braided cables maintain performance in continuous temperatures up to 200°C, with special specifications capable of withstanding up to 300°C . This makes them ideal for high-temperature applications where conventional cables would fail.

Superior Flexibility:

Despite their robust construction, DLX heating cables offer remarkable flexibility with a minimum bending radius of approximately 10 times the cable diameter , allowing for installation in tight spaces and around complex geometries.

Fireproof and Flame Retardant:

The silicone rubber insulation combined with fiberglass braiding creates a cable that meets fire resistance standards including UL-94 vertical flame test , ensuring enhanced safety in potentially flammable environments.

Excellent Electrical Properties:

With a high voltage resistance of up to 3000V and insulation resistance ≥100MΩ, our heating cables provide reliable electrical insulation even in demanding conditions.

Chemical and Environmental Resistance:

DLX silicone braided heating cables resist oils, acids, alkalis, ozone, and moisture , ensuring long-term performance in challenging industrial environments.

Long Service Life:

The premium materials and robust construction contribute to an extended operational lifespan, even in continuous flexing applications rated for over 10 million cycles .

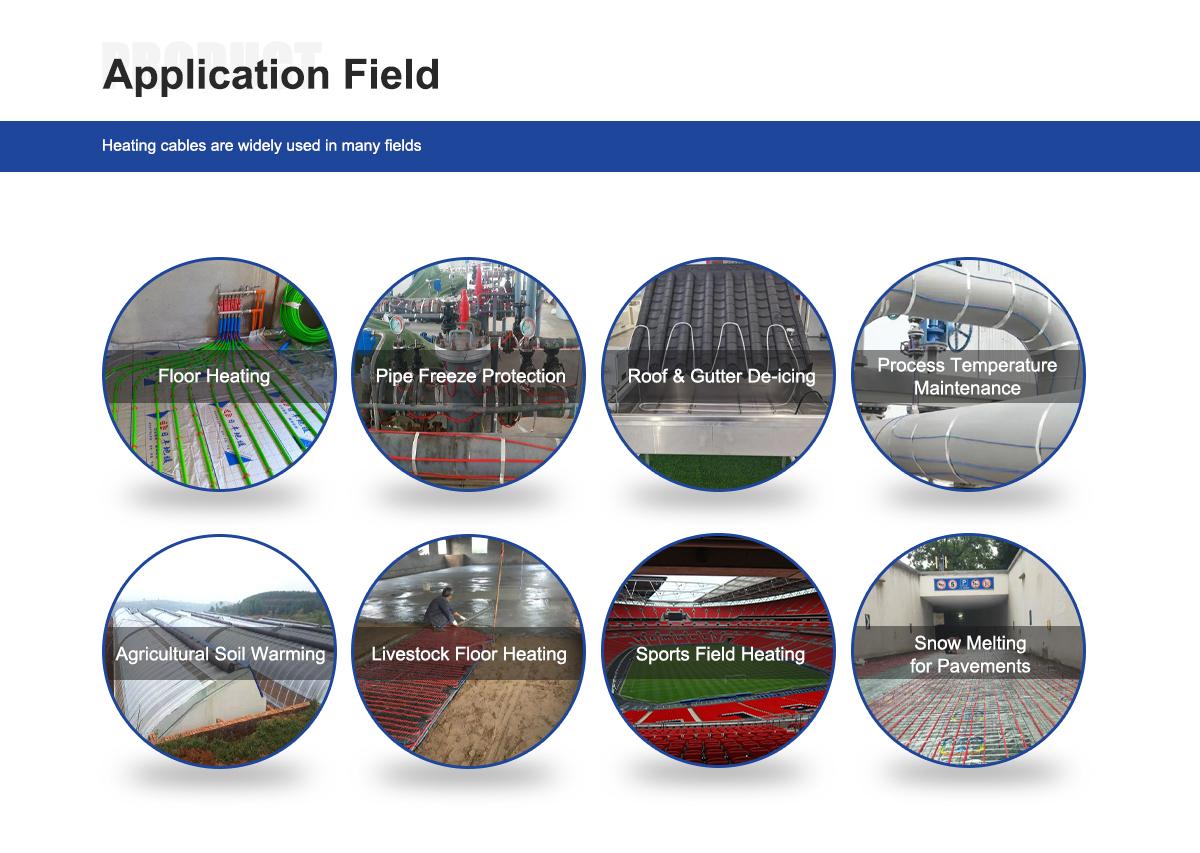

Products Applications

DLX silicone braided heating cables serve a wide range of heating applications across multiple industries:

Industrial Heating Systems

Pipe Tracing and Freeze Protection: Prevent freezing of pipes and components in industrial facilities

Tank Heating: Maintain optimal viscosity of fluids in storage tanks

Process Heating: Provide precise heating for industrial manufacturing processes

Appliance and Equipment Manufacturing

Home Appliances: Used in various appliances including refrigerators, microwave ovens, disinfection cabinets, electric towel rails, and foot baths

Thermal Therapy Equipment: heated seats, pet pads, and massage equipment

Medical and Beauty Instruments: Provide controlled heating in medical and beauty devices

Specialized Applications

Aerospace and Aviation: Heating solutions for aircraft and aerospace components

Foundries and Steel Plants: High-temperature resistant heating for metal processing facilities

Food Processing Equipment: Heating for ovens, boilers, and food processing machinery

Outdoor and Harsh Environments: Durable heating solutions for applications exposed to weather, chemicals, or mechanical stress

About Us

CHANGZHOU DLX ALLOY CO, LTD was established in 2002. Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy , NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

FAQs:

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.