36ga 38ga 26ga 32ga 40ga Nichrome Cr20Ni80 Cr10Ni90 Ni80 Ni90 Fused Clapon Alien Wire

- Product Details

We’re super stoked about our range of Nichrome Cr20Ni80 and Cr10Ni90 fused Clapton and alien wires, available in 26ga, 32ga, 36ga, 38ga, and 40ga—perfect for crafting high-performance resistance coils, especially for vaping enthusiasts and industrial applications. These wires are designed to deliver top-notch heat and durability in a variety of setups.

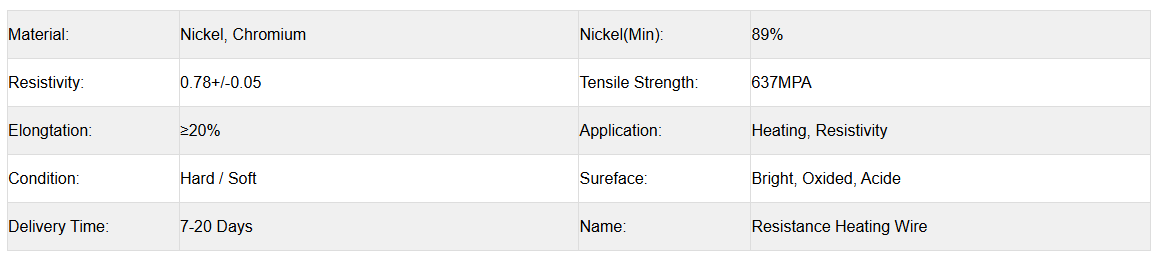

Cr20Ni80 (80% nickel, 20% chromium) and Cr10Ni90 (90% nickel, 10% chromium) are powerhouse alloys. Cr20Ni80 brings excellent oxidation resistance, forming a protective layer that fights corrosion, even in intense conditions, while Cr10Ni90 offers slightly higher strength and lower resistivity (around 0.95 µΩ·m vs. 1.09 µΩ·m) for efficient power delivery. Both can handle temperatures up to 1200°C, making them ideal for high-heat environments like vaping coils or small-scale heating elements. The fused Clapton and alien designs—think multiple cores wrapped with thinner wires—increase surface area for better heat distribution and vapor production, giving you that perfect hit or consistent performance.

The range of gauges (26ga to 40ga) gives you tons of flexibility. Thicker 26ga wires are great for lower-resistance builds, while the finer 38ga and 40ga are perfect for intricate, high-resistance coils. With tensile strengths around 650 MPa for Cr20Ni80 and 700 MPa for Cr10Ni90, these wires are built to last, reducing wear and tear even under heavy use. Their formability makes them a dream to work with, letting you craft complex coil designs without breaking a sweat.

The vaping and electronics industries in 2025 are all about performance and customization, and our Nichrome wires are right on trend. Vapers are chasing bigger clouds and better flavor, driving demand for advanced coil designs like fused Claptons and aliens. These wires also fit into broader industrial trends for durable, high-efficiency heating elements in electronics and small appliances. Being 100% recyclable, they’re a win for eco-conscious manufacturing, too.

Ni90Cr10 Heating Resistance Wire

Ni90Cr10 is kind of nickel-chromium alloy products, it is suitable for temperature applications up to 1250°C. Chromium content provides very good life time, it is usually used as a vape heating element.

Ni90Cr10 is characterized by high resistivity, good oxidation resistance, good ductility after use and excellent weldability. NiCr Alloy is a good material for heating industry.

Thermistors

Ni90Cr10 resistance wire is widely used as a thermistor material, employed in the sensitive elements of temperature sensors. By measuring the resistance change of the wire, temperature variations in the environment can be accurately reflected.

High Precision Measurement

Ni90Cr10 resistance wire exhibits a low temperature coefficient of resistance and good linearity, enabling temperature sensors to achieve high-precision temperature measurements, especially in industrial and scientific applications that require high accuracy.

Stability

Due to its excellent temperature stability, Ni90Cr10 resistance wire temperature sensors can provide long-term stable and reliable performance, unaffected by external environmental factors.

Industrial and Laboratory Applications

Ni90Cr10 resistance wire temperature sensors are widely used in industrial process monitoring, laboratory research, and temperature control systems. They can measure temperature variations ranging from very low to high temperatures and provide accurate temperature data.

Nichrome 90 heating wire coils are commonly used in a variety of applications where consistent, reliable heating is required. Here’s a detailed look at the properties, uses, and advantages of Nichrome 90 heating wire coils:

Advantages of Nichrome 90 Heating Wire Coils:

Durability:

Long-lasting and resistant to wear and tear, even in continuous high-temperature applications.

Consistency:

Provides consistent and reliable heating performance, crucial for precision applications.

Versatility:

Can be used in a wide range of heating applications, both domestic and industrial.

Ease of Fabrication:

Can be easily coiled, shaped, and fabricated to meet specific requirements of different applications.

Maintenance and Handling:

Oxidation Layer:

Over time, an oxide layer may form on the surface of the Nichrome wire. This layer can protect the underlying material from further oxidation, but excessive build-up should be monitored and cleaned if necessary.

Careful Handling:

Care should be taken when handling and installing Nichrome 90 wire coils to avoid kinks and bends that could affect their performance.

Conclusion:

Nichrome 90 heating wire coils are a versatile and reliable choice for a wide range of high-temperature applications. Their combination of high resistivity, thermal stability, and resistance to oxidation and corrosion makes them ideal for both domestic and industrial heating solutions. Whether used in household appliances, industrial equipment, or precision laboratory devices, Nichrome 90 coils provide consistent and efficient heating performance.

About Us:

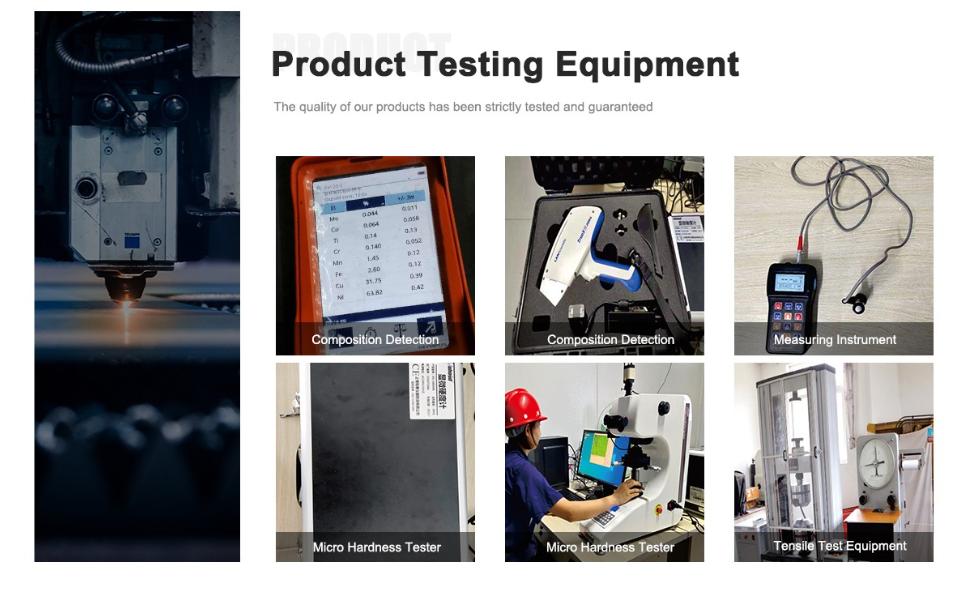

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why use Nichrome Cr20Ni80 and Cr10Ni90 for fused Clapton alien wire?

Their high heat and oxidation resistance make them ideal for reliable, high-performance coils.

What’s the difference between Cr20Ni80 and Cr10Ni90?

Cr20Ni80 has better oxidation resistance, while Cr10Ni90 offers higher strength and slightly lower resistivity.

Can these wires handle high vaping temperatures?

Yup, they’re stable up to 1200°C, perfect for intense vaping setups.

Why choose fused Clapton or alien wire designs?

They increase surface area for better heat distribution and vapor production.

Are these wires corrosion-resistant?

Totally, they form a protective oxide layer to resist corrosion in harsh conditions.

Are these Nichrome wires recyclable?

100% recyclable, aligning with sustainable manufacturing trends.

Can these gauges (26ga to 40ga) be used for precision vaping?

Absolutely, their range of sizes supports both small and complex coil builds.

Are these wires cost-effective for vaping applications?

Yes, they balance performance and affordability for high-quality vape builds.