Durable Nichrome Wire: Wieland W.Nr 2.4869, HV400-500 Hardness, Excellent Corrosion Resistance

- Product Details

Product Description:

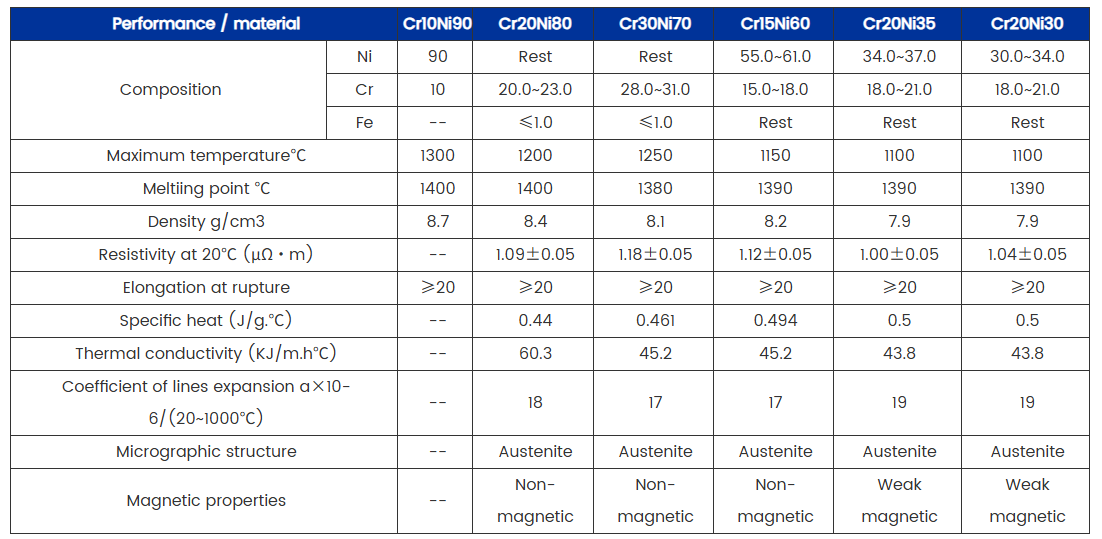

One of the key features of our Nichrome Alloy is its impressive yield strength range of 200-300 MPa. This means that it can withstand significant stress and pressure without breaking or deforming, making it a reliable choice for demanding applications.

In addition to its high yield strength, our Nichrome Alloy also boasts excellent thermal expansion properties, with a range of 13-17 μm/mK. This means that it can handle changes in temperature without cracking or warping, making it ideal for use in high-temperature environments.

The density of our Nichrome Alloy is also noteworthy, coming in at 8.4 G/cm3. This makes it a relatively lightweight material that is easy to work with and handle, while still providing excellent strength and durability.

When it comes to hardness, our Nichrome Alloy is no slouch either, with a hardness range of HV400-500. This means that it is resistant to wear and tear, making it ideal for use in high-stress environments where other materials may not hold up as well.

Finally, our Nichrome Alloy is also non-magnetic, which makes it a great choice for applications where magnetic interference could cause issues. Whether you're working in electronics, aerospace, or any other industry where magnetic properties are a concern, our Nichrome Alloy can provide the performance and reliability you need.

So if you're in the market for high-quality Nitinol Materials, look no further than our Nichrome Alloy product. With its impressive strength, durability, and unique properties, it is the perfect choice for a wide range of applications.

We’re stoked about our Wieland W.Nr 2.4869 Nichrome wire—it’s a tough, reliable choice for industrial heating applications where durability and corrosion resistance are non-negotiable. With a hardness of HV400-500, this wire is built to last and perform like a champ in the harshest environments.

This Nichrome wire, a nickel-chromium alloy (80% nickel, 20% chromium), can handle temperatures up to 1200°C without breaking a sweat. Its corrosion resistance is top-tier, forming a protective oxide layer that laughs off harsh conditions, making it perfect for industrial furnaces, kilns, and even specialized Heating Element s. The HV400-500 hardness gives it extra strength and wear resistance, so it holds up under stress where softer materials might fail. Plus, its electrical resistivity of about 1.09 µΩ·m stays rock-steady, delivering consistent heat every time.

The high hardness and formability make this wire a dream to work with. We can shape it into tight coils or custom designs for all sorts of heating systems, from heavy-duty industrial setups to precision applications. Its durability means fewer replacements, saving time and money in the long run.

The industry in 2025 is all about tough, efficient materials, and our W.Nr 2.4869 Nichrome wire fits right in. There’s a big push for components that can withstand high heat and corrosion while keeping maintenance low, especially in sectors like metal processing, aerospace, and ceramics. Being 100% recyclable, it’s also a great match for the growing focus on sustainable manufacturing. As precision heating systems trend upward, this wire’s consistent performance and strength make it a go-to choice.

Sure, FeCrAl alloys like Kanthal A-1 can push slightly higher temperatures, but our Nichrome wire’s corrosion resistance and high hardness give it an edge in environments where wear and tear are a concern. Just avoid extreme reducing atmospheres, though this wire handles most conditions like a pro.

From industrial kilns to specialized heaters, our Wieland W.Nr 2.4869 Nichrome wire delivers the durability, corrosion resistance, and heat performance that keep industries running strong.

Features:

Product Name: Nichrome Alloy

Thermal Expansion: 13-17 μm/mK

Yield Strength: 200-300 MPa

Applications: Heating Elements, Furnaces, Electrical Components

Magnetic Properties: Non-magnetic

Corrosion Resistance: Excellent

This Nichrome Alloy product is a great alternative to Nitinol. With its excellent corrosion resistance and non-magnetic properties, it is perfect for heating elements, furnaces, and electrical components. Its yield strength of 200-300 MPa and thermal expansion of 13-17 μm/mK make it a reliable and durable choice.

Customization:

Brand Name: DLX

Model Number: Nichrome Wire

Place of Origin: China JiangSu

Certification: CE

Minimum Order Quantity: 5

Packaging Details: Spool package with Carton box, Coil package with polybag for Resistance wire

Delivery Time: 5-21 days

Payment Terms: L/C, T/T, Western Union, MoneyGram

Supply Ability: 300 tons per month

Hardness: HV400-500

Corrosion Resistance: Excellent

Electrical Resistivity: 1.1-1.2 μΩm

Magnetic Properties: Non-magnetic

Applications: Heating Elements, Furnaces, Electrical Components

Support and Services:

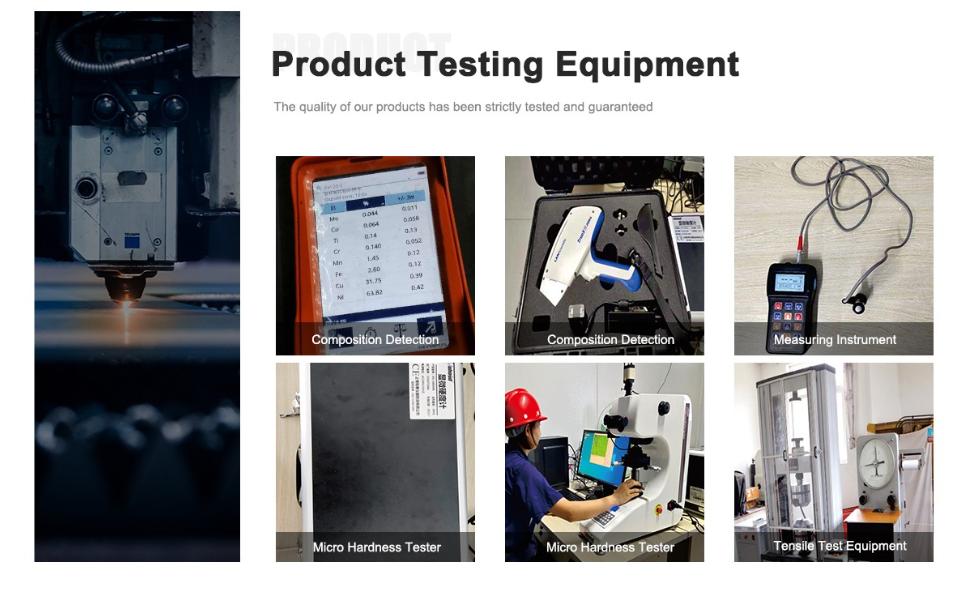

Our Nichrome Alloy product comes with technical support and services to ensure optimal performance and customer satisfaction:

Expert consultation on product selection and application

Technical assistance for installation and maintenance

Product testing and analysis for quality control

Customized solutions for unique customer needs

Training and education on product use and safety

We are committed to providing our customers with the highest level of support and service for our Nichrome Alloy product.

Packing and Shipping:

Product Packaging:

The Nichrome Alloy product will be packaged securely in a durable cardboard box to ensure safe transport.

The product will be wrapped in protective bubble wrap to prevent any damage during shipping.

A label with the product name and details will be placed on the box for easy identification.

Shipping:

The product will be shipped via a reputable courier service within 2 business days of receiving the order.

Customers will receive a tracking number once the product has been shipped.

Please allow 5-7 business days for delivery.

If there are any issues with the product or shipping, please contact our customer service team for assistance.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

Why use Wieland W.Nr 2.4869 Nichrome wire for heating applications?

Its high heat stability and corrosion resistance make it ideal for reliable, long-lasting heating systems.

What does the HV400-500 hardness mean for this wire?

It ensures superior strength and wear resistance, perfect for demanding industrial environments.

Can this wire handle high temperatures?

Yup, it’s stable up to 1200°C, great for intense heating applications.

How does its corrosion resistance compare to other alloys?

It’s top-notch, forming a protective oxide layer that outperforms many other materials.

Is this Nichrome wire suitable for harsh environments?

Totally, its corrosion resistance and hardness make it a champ in tough conditions.

Is Wieland W.Nr 2.4869 wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be shaped for custom heating elements?

Absolutely, it’s formable enough for complex coil designs without losing strength.

Is this wire cost-effective for industrial use?

Yes, its durability and performance balance out the cost for long-term savings.