Furnaces Nichrome Alloy Wire with Ni-Cr-Fe Chemical Composition

- Product Details

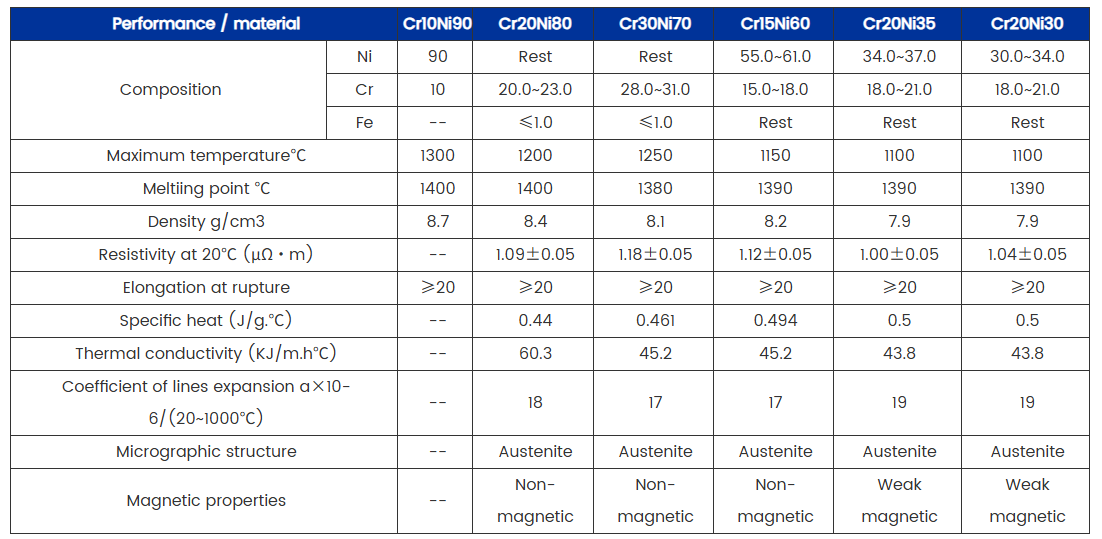

One of the standout features of this alloy is its excellent corrosion resistance, making it ideal for use in harsh environments where corrosion can be a concern. Additionally, our Nichrome Alloy has a low electrical resistivity of 1.1-1.2 μΩm, making it an excellent choice for heating applications.

We offer four grades of Nichrome Alloy: Cr15Ni60, Cr20Ni35, Cr20Ni30, and Cr30Ni70. Each grade has its own unique properties and is suitable for different applications. These grades are carefully formulated to provide the best possible performance in a variety of environments.

Our Nichrome Alloy has a melting point of 1400-1450°C, which is ideal for applications that require high-temperature resistance. This makes it an excellent choice for use in high-temperature heating elements, such as those found in ovens and furnaces.

Overall, our Nichrome Alloy product is a reliable and versatile material that offers excellent performance in a variety of applications. Whether you need a material that is corrosion-resistant, has a low electrical resistivity, or can withstand high temperatures, our Nichrome Alloy is the perfect choice.

We’re super stoked about our Ni-Cr-Fe Nichrome alloy wire, crafted for furnaces and built to handle the heat like a champ. With its killer mix of nickel, chromium, and iron, this wire is a go-to for industries needing reliable, cost-effective heating solutions.

This Nichrome wire, with roughly 35% nickel, 20% chromium, and iron for balance, is designed to take on furnace temperatures up to 1100°C without breaking a sweat. Its corrosion resistance is top-notch, forming a protective oxide layer that keeps rust and wear at bay, even in the intense, high-heat environment of industrial furnaces. The Ni-Cr-Fe composition gives it solid mechanical strength—around 600 MPa tensile strength—making it tough enough for heavy-duty use while keeping costs lower than high-nickel alloys.

With an electrical resistivity of about 1.04 µΩ·m, it delivers steady, efficient heat, perfect for everything from heat-treating furnaces to ceramic kilns. Its formability is a big win—we can shape it into coils, loops, or custom heating elements to fit any furnace design, no problem. Plus, it’s durable enough to last years, saving you from constant replacements.

The industry in 2025 is all about balancing performance and sustainability, and our Ni-Cr-Fe Nichrome wire nails it. There’s a huge demand for affordable, high-temperature materials in sectors like metal processing, glass production, and industrial manufacturing. Being 100% recyclable, this wire’s a growing trend toward eco-friendly production. As furnaces get more precision and automation, its stable resistivity and versatility make it a favorite for consistent, tailored heating solutions.

Sure, Cr20Ni80 Nichrome can push slightly higher temperatures, and FeCrAl alloys like Kanthal A-1 can go even hotter, but our Ni-Cr-Fe wire’s corrosion resistance and budget-friendly price make it a sweet spot for most furnace applications. Just keep it away from extreme reducing atmospheres, though it handles most furnace conditions like a pro.

From massive industrial furnaces to specialized heat-treatment setups, our Ni-Cr-Fe Nichrome alloy wire brings the heat, durability, and affordability that keep industries running hot and efficient.

Applications:

The Nichrome Wire is manufactured in China JiangSu and is certified with CE, ensuring its quality and safety. The product is available for a minimum order quantity of 5 and can be packaged in spool or coil packages with carton boxes or polybags. It has a quick delivery time of 5-21 days and can be paid for using L/C, T/T, Western Union, or MoneyGram. DLX Alloy has a supply ability of 300 tons per month, making it a reliable source for Nichrome Wire.

In addition to its use in heating elements and electrical components, the Nichrome Wire also has excellent corrosion resistance, making it suitable for use in marine and chemical applications. Its thermal expansion of 13-17 μm/mK also makes it useful in applications that require dimensional stability under changing temperatures.

One specific application where the Nichrome Wire can be used is in the manufacturing of Nitinol Pipe. Nitinol is a nickel-titanium alloy with shape memory and superelasticity properties, making it useful in medical and dental applications. The Nichrome Wire can be used in the manufacturing process of Nitinol Pipe, ensuring its high quality and durability.

Overall, DLX Alloy's Nichrome Wire is a reliable and versatile product with a wide range of applications. Its high-quality manufacturing, certification, and supply ability make it a top choice for those in need of a high-performance wire.

Customization:

Our Nichrome Wire is versatile and can be used for various applications such as heating elements, furnaces, and electrical components. It has a tensile strength of 400-500 MPa and is available in the form of wire. The chemical composition of our Nichrome Wire is Ni-Cr-Fe.

At DLX Alloy, we also offer customization services for our products to meet your specific needs. Contact us for more information on how we can customize our Nichrome Wire to fit your requirements.

Keywords: Nitinol Pipe, Nitinol, Nitinol Materials

Support and Services:

Nichrome alloy is a high-performance alloy that is commonly used in heating elements and resistance wires. Our technical support team is available to provide assistance with any questions related to the selection, use, and maintenance of Nichrome alloy products. We offer a range of services to support our customers, including:

Product selection guidance

Custom alloy development

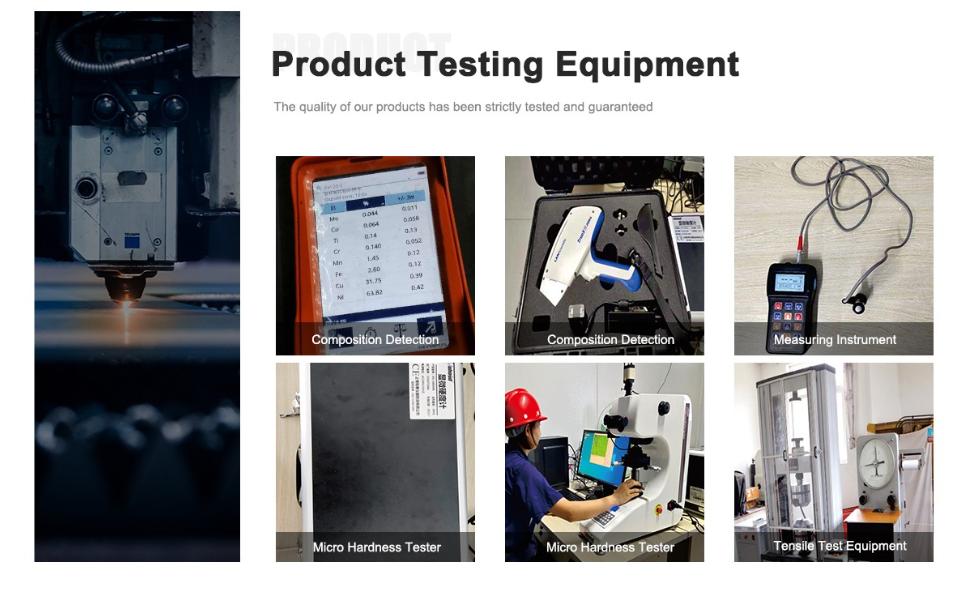

Material testing and analysis

Technical training and education

Product troubleshooting and repair

Warranty support

Our team of experts is dedicated to ensuring that our customers have access to the knowledge and resources they need to get the most out of their Nichrome alloy products. Contact us today to learn more about our technical support and service offerings.

Packing and Shipping:

Product Packaging:

The Nichrome Alloy product will be packaged in a sturdy cardboard box.

The box will be lined with bubble wrap to ensure safe transit.

The product will be placed in a plastic bag for added protection.

The package will be labeled with the product name, quantity, and any other necessary information.

Shipping:

The package will be shipped via a trusted courier service.

The shipping cost will be calculated based on the destination and weight of the package.

The package will be insured for its full value to provide peace of mind to the customer.

The customer will be provided with a tracking number so they can monitor the progress of their shipment.

Delivery times may vary depending on the destination, but we strive to ensure timely delivery.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why use Ni-Cr-Fe Nichrome wire for furnace applications?

Its heat and corrosion resistance make it perfect for reliable, long-lasting furnace performance.

How does Ni-Cr-Fe Nichrome compare to standard Nichrome?

The iron addition boosts strength and affordability while maintaining high heat resistance.

Can this wire handle continuous furnace temperatures?

Yup, it’s stable up to 1100°C, ideal for most industrial furnaces.

Is this wire corrosion-resistant in furnace environments?

Totally, it forms a protective oxide layer to fight corrosion under high heat.

What’s the benefit of its Ni-Cr-Fe composition?

It combines durability, heat resistance, and cost savings for furnace applications.

Is this Nichrome wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be customized for specific furnace designs?

Absolutely, its formability allows for tailored heating element shapes.

Is this wire cost-effective for large-scale furnace use?

Yes, it offers great performance at a budget-friendly price point.