High Nickel Cathode Precursor Ni96 Ni90 Ni88 Ni83 Ni80 Ternary Precursor Wire For Oven

- Product Details

We’re super excited about our high nickel cathode precursor wire—Ni96, Ni90, Ni88, Ni83, and Ni80 ternary precursor wire—designed specifically for oven heating applications. This stuff is built to keep ovens running hot, efficient, and reliable, no matter the demands.

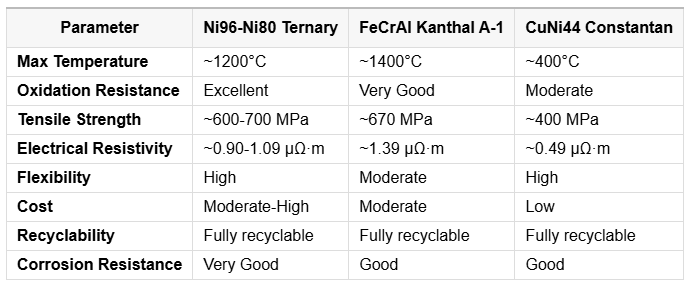

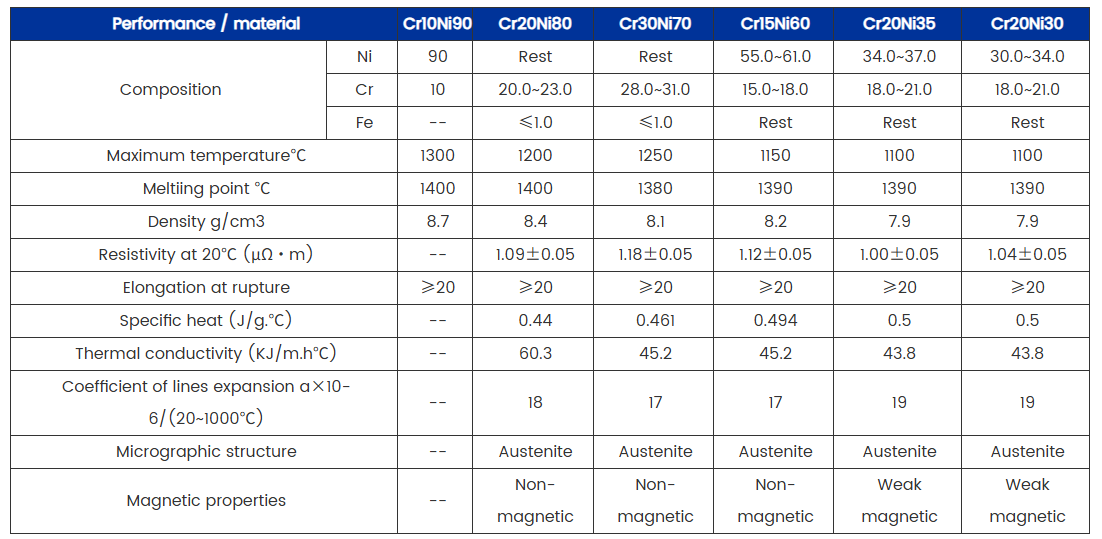

These wires, ranging from 80% to 96% nickel with chromium and other elements, are all about high performance. Higher nickel content, like Ni96, gives you lower electrical resistivity (around 0.90 µΩ·m), making it super efficient for quick heat-up in ovens. Ni80, on the other hand, balances cost and performance with a resistivity closer to 1.09 µΩ·m. All of them handle temperatures up to 1200°C with ease, and their excellent oxidation resistance forms a protective layer to fight off corrosion, even in the intense heat of industrial ovens.

The tensile strength, ranging from 600 to 700 MPa depending on the grade, ensures these wires are tough enough to last for years, cutting down on maintenance costs. Their flexibility is a big win—we can shape them into coils or custom heating elements to fit any oven design, from household appliances to industrial baking systems. The ternary composition, often including traces of cobalt and manganese, boosts stability and performance, making these wires a top choice for high-demand applications.

The industry in 2025 is leaning hard into efficiency and sustainability, and our high nickel wires are right on trend. There’s a growing need for materials that deliver consistent heat while keeping energy costs low, especially in commercial and industrial oven manufacturing. These wires’ recyclability—100% recyclable—makes them a perfect fit for eco-conscious production. Plus, as ovens get smarter and more precise, the low resistivity and durability of Ni96 to Ni80 wires keep them in high demand.

Sure, FeCrAl alloys like Kanthal A-1 can push slightly higher temperatures, but our high nickel wires shine with their oxidation resistance and efficiency, especially for ovens where quick, even heating is key. Just avoid extreme reducing atmospheres, though these wires handle most oven conditions like champs.

From home kitchen ovens to massive industrial baking systems, our Ni96 to Ni80 ternary precursor wire delivers the heat, durability, and efficiency that keep ovens firing on all cylinders.

Ni90Cr10 Heating Resistance Wire

Ni90Cr10 is kind of nickel-chromium alloy products, it is suitable for temperature applications up to 1250°C. Chromium content provides very good life time, it is usually used as a vape heating element.

Ni90Cr10 is characterized by high resistivity, good oxidation resistance, good ductility after use and excellent weldability. NiCr Alloy is a good material for heating industry.

Thermistors

Ni90Cr10 resistance wire is widely used as a thermistor material, employed in the sensitive elements of temperature sensors. By measuring the resistance change of the wire, temperature variations in the environment can be accurately reflected.

High Precision Measurement

Ni90Cr10 resistance wire exhibits a low temperature coefficient of resistance and good linearity, enabling temperature sensors to achieve high-precision temperature measurements, especially in industrial and scientific applications that require high accuracy.

Stability

Due to its excellent temperature stability, Ni90Cr10 resistance wire temperature sensors can provide long-term stable and reliable performance, unaffected by external environmental factors.

Industrial and Laboratory Applications

Ni90Cr10 resistance wire temperature sensors are widely used in industrial process monitoring, laboratory research, and temperature control systems. They can measure temperature variations ranging from very low to high temperatures and provide accurate temperature data.

Nichrome 90 heating wire coils are commonly used in a variety of applications where consistent, reliable heating is required. Here’s a detailed look at the properties, uses, and advantages of Nichrome 90 heating wire coils:

Properties:

High Electrical Resistivity:

Nichrome 90 has a high electrical resistivity, making it ideal for converting electrical energy into heat efficiently.

High Melting Point:

The alloy has a high melting point of approximately 1400°C (2552°F), allowing it to perform well in high-temperature applications.

Oxidation and Corrosion Resistance:

Excellent resistance to oxidation and corrosion at high temperatures, which helps to prolong the lifespan of the coils.

Thermal Stability:

Maintains stable resistance and mechanical properties even at elevated temperatures, ensuring consistent heating performance.

Mechanical Strength and Ductility:

Good mechanical strength and ductility, making it easy to form into coils and other shapes without breaking.

Non-Magnetic:

The non-magnetic nature of Nichrome 90 can be advantageous in applications where magnetic interference must be avoided.

Applications:

Domestic Appliances:

Used in heating elements for toasters, hair dryers, electric ovens, and space heaters.

Industrial Furnaces and Kilns:

Employed in industrial furnaces and kilns for processes requiring sustained high temperatures, such as metal casting, glass making, and ceramic firing.

Laboratory Equipment:

Commonly used in laboratory heating devices, such as heating mantles and high-temperature ovens.

Vaporizers and E-Cigarettes:

Utilized in the coils of vaporizers and e-cigarettes due to its reliable and consistent heating properties.

Hot Wire Cutting:

Used in hot wire foam cutters and other cutting equipment where a heated wire is required to melt through materials.

Resistance Resistors:

Suitable for making precision resistors and rheostats due to its stable resistance characteristics.

About Us:

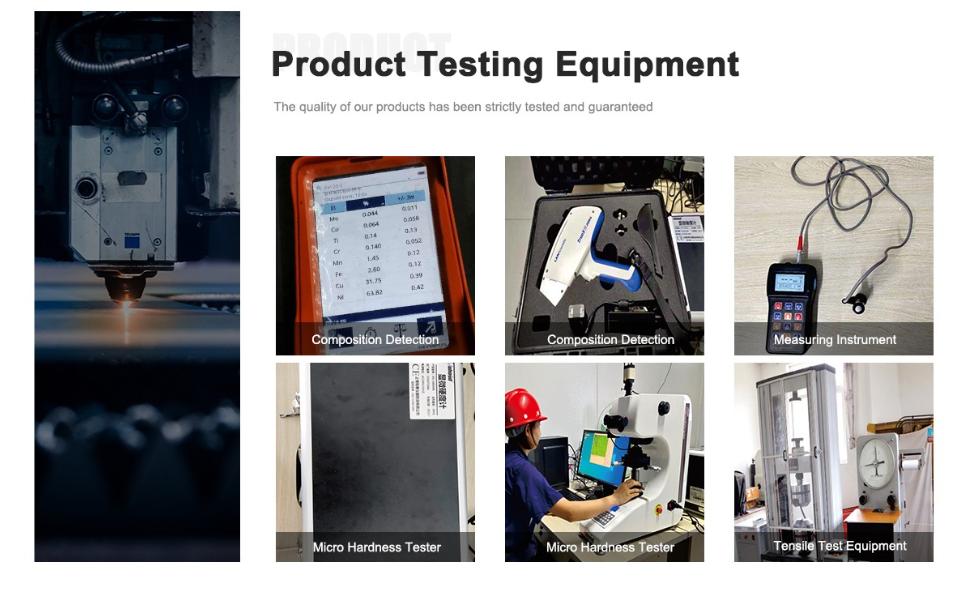

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why use high nickel Ni96-Ni80 ternary precursor wire for ovens?

Its high thermal stability and low resistivity make it ideal for efficient, reliable oven heating.

How do Ni96, Ni90, Ni88, Ni83, and Ni80 differ?

Higher nickel content (e.g., Ni96) offers lower resistivity, while lower nickel (e.g., Ni80) balances cost and performance.

Can this wire handle high oven temperatures?

Yup, it’s stable up to 1200°C, perfect for intense oven environments.

Is this wire resistant to oxidation?

Totally, it forms a protective oxide layer to resist corrosion in high-heat conditions.

How durable is this high nickel wire in ovens?

Super durable, lasting years with minimal maintenance in tough conditions.

Is this wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be customized for specific oven designs?

Absolutely, its formability allows for tailored heating element shapes.

Is this wire cost-effective for oven applications?

Yes, it offers great performance at a reasonable price for industrial ovens.