Ideal Material Good ductility Stable Resistance Nichrome Wire Heating Element

- Product Details

We’re thrilled about our Nichrome wire heating element—it’s the ideal material for industries needing a reliable, flexible, and high-performing heating solution. With its awesome ductility and stable resistance, this wire is a total standout for all kinds of heating applications.

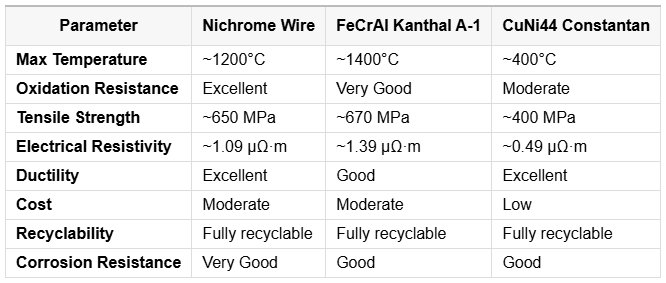

This Nichrome wire, a nickel-chromium alloy with 80% nickel and 20% chromium, is built to handle scorching temperatures—up to 1200°C without blinking. Its oxidation resistance is top-notch, forming a protective layer that keeps corrosion at bay, even in harsh industrial environments. The stable electrical resistivity, around 1.09 µΩ·m, ensures consistent heat output, making it perfect for everything from industrial furnaces to small appliance heaters.

The ductility is a big deal here. With excellent flexibility, we can bend, coil, or shape this wire into intricate designs without worrying about it snapping. That’s a game-changer for manufacturers working on complex or compact heating elements. Plus, with a tensile strength of about 650 MPa, it’s tough enough to last for years, cutting down on maintenance and replacements.

The industry in 2025 is all about precision and sustainability, and our Nichrome wire nails both. There’s a huge demand for materials that can deliver reliable heat while being easy to work with, especially in sectors like electronics, automotive, and industrial manufacturing. Its 100% recyclability makes it a great fit for eco-conscious production trends. As compact, high-efficiency heating systems gain traction, this wire’s ductility and stable performance make it a top choice.

Sure, FeCrAl alloys like Kanthal A-1 can push slightly higher temperatures, but our Nichrome wire’s ductility and oxidation resistance make it a go-to for most heating applications, especially where intricate designs are needed. Just steer clear of extreme reducing atmospheres, though it handles most conditions like a pro.

From kilns to toasters, our Nichrome wire heating element delivers the heat, flexibility, and reliability that keep industries fired up and running smoothly.

Product Description:

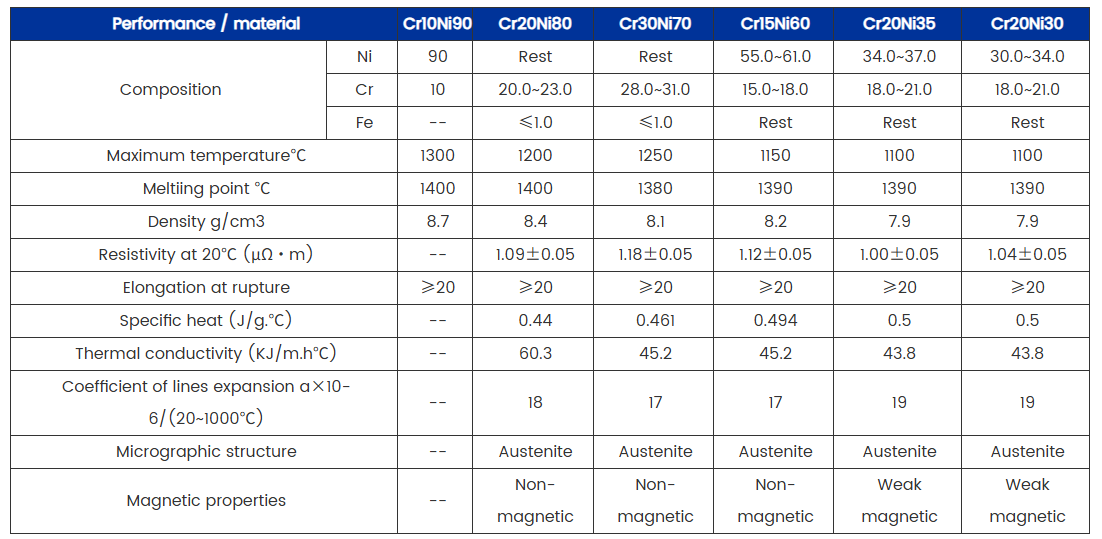

One of the most widely used types of nichrome alloy is Cr20Ni80. This alloy has a high nickel content of 80% and chromium content of 20%. It is known for its high resistance to oxidation and corrosion, making it ideal for use in environments where exposure to high temperatures and corrosive agents is expected. Cr20Ni80 is also a popular choice for heating elements in a wide variety of industrial and commercial applications.

Another key attribute of Nichrome Alloy is its non-magnetic properties. This characteristic makes it an excellent choice for use in applications where magnetic interference is a concern. For example, it is ideal for use in electronic devices and medical equipment where magnetic fields could interfere with the functionality of the equipment.

In addition to its high temperature and corrosion resistance, the Nichrome Alloy is also known for its high hardness. It has a hardness rating of HV400-500, making it a durable and long-lasting material for use in a wide range of applications.

Overall, Nichrome Alloy is a versatile and reliable material that is widely used in the production of nichrome heating elements. Its excellent thermal conductivity, high resistance to corrosion and oxidation, non-magnetic properties, and high hardness make it an ideal choice for a wide range of industrial and commercial applications.

Features:

Product Name: Nichrome Alloy

Tensile Strength: 400-500 MPa

Forms: Wire, Sheet, Strip, Rod, Tube

Electrical Resistivity: 1.1-1.2 μΩm

Chemical Composition: Ni-Cr-Fe

Elongation: 20-30%

Our Nichrome Alloy product, also known as Cr20Ni80, is a high strength alloy with a tensile strength of 400-500 MPa. It comes in various forms including wire, sheet, strip, rod, and tube. With an electrical resistivity of 1.1-1.2 μΩm and a chemical composition of Ni-Cr-Fe, this alloy is perfect for creating Nichrome coils. It also has an elongation of 20-30%, making it a versatile and durable material for various applications.

Technical Parameters:

| Applications | Heating Elements, Furnaces, Electrical Components |

| Electrical Resistivity | 1.1-1.2 μΩm |

| Thermal Expansion | 13-17 μm/mK |

| Elongation | 20-30% |

| Thermal Conductivity | 15-20 W/mK |

| Yield Strength | 200-300 MPa |

| Corrosion Resistance | Excellent |

| Melting Point | 1400-1450°C |

| Forms | Wire, Sheet, Strip, Rod, Tube |

| Hardness | HV400-500 |

Support and Services:

The Nichrome Alloy is a high-resistance alloy made of nickel, chromium, and sometimes iron. It is commonly used in heating elements, furnace components, and electrical appliances. Our product technical support and services for Nichrome Alloy include:

Expert advice on material selection, design, and processing

Customized alloy composition and manufacturing

Testing and analysis of physical and mechanical properties

Technical documentation and material certification

On-site technical support and troubleshooting

Training and education on proper handling, installation, and maintenance

Our team of specialists is dedicated to providing the highest level of technical support and services to help you achieve optimal performance and efficiency with your Nichrome Alloy applications.

Packing and Shipping:

Product Packaging:

The Nichrome Alloy product will be packaged in a sturdy cardboard box to ensure safe transportation. The box will be labeled with the product name, specifications, and safety instructions.

Shipping:

Our standard shipping method for the Nichrome Alloy product is through a reliable courier service. The estimated delivery time varies depending on the destination, but usually takes between 3-7 business days. We also offer expedited shipping options for an additional fee. Customers will receive a tracking number once the order has shipped.

About Us:

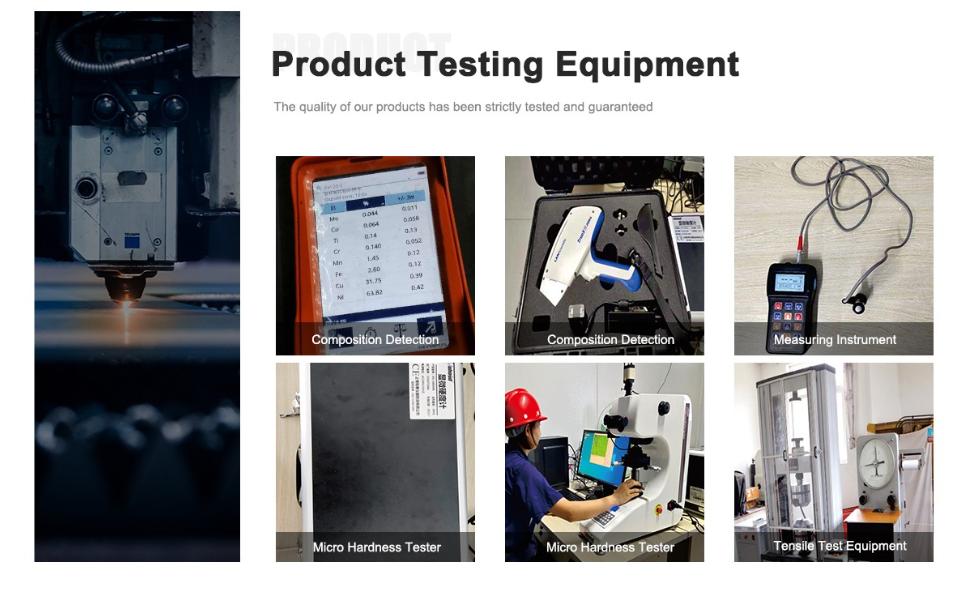

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why is this Nichrome wire ideal for heating elements?

Its high heat resistance and stable performance make it perfect for reliable heating systems.

How does its ductility benefit manufacturing?

The wire’s flexibility allows for intricate designs and easy shaping without breaking.

Can this Nichrome wire handle continuous high temperatures?

Yup, it’s stable up to 1200°C, great for most industrial and appliance heating needs.

Is this wire resistant to corrosion?

Totally, it forms a protective oxide layer to fight off corrosion in tough conditions.

How consistent is the electrical resistance?

Super consistent, ensuring steady heating performance across applications.

Is this Nichrome wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be used in small-scale heating devices?

Absolutely, its ductility makes it ideal for compact, precision heating elements.

Is this wire cost-effective for heating applications?

Yes, it offers top-notch performance at a reasonable price point.