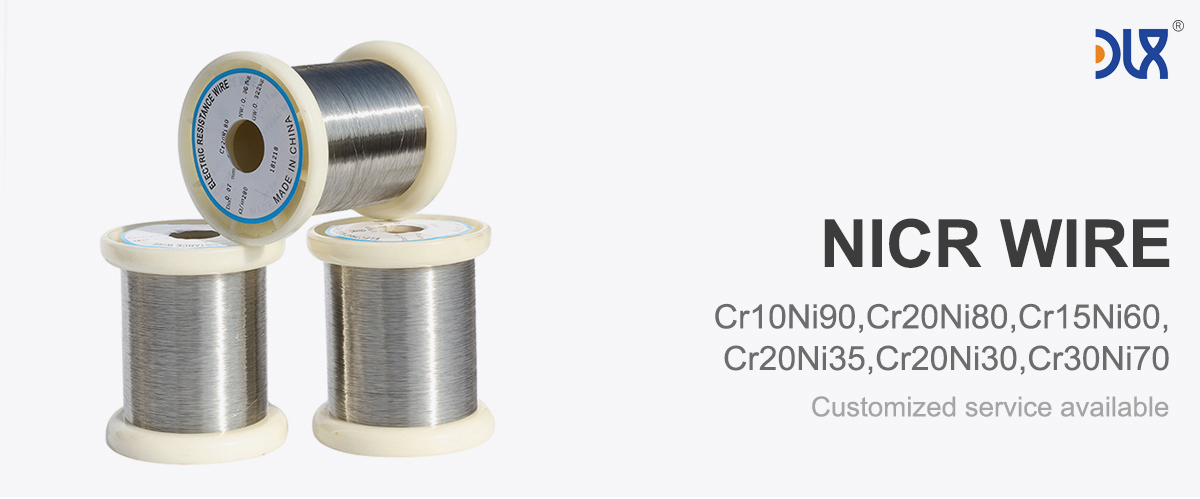

NiCr Alloy Wire for High-Temperature Applications with HRC 40-45 Hardness and 200 GPa Elasticity

- Product Details

One of the key features of our NiCr Alloy product is its low electrical resistivity of 1.2 µΩ.m. This makes it an ideal material for use in electrical heating applications, where it can provide efficient and reliable heating performance. Additionally, its high tensile strength of 637MPA ensures that it can withstand high stresses and loads, making it suitable for use in demanding industrial environments.

Another important attribute of our NiCr Alloy product is its high thermal conductivity of 100 W/mK. This means that it can transfer heat quickly and efficiently, making it ideal for use in high-temperature applications where heat dissipation is critical. Its thermal expansion coefficient of 13.0 µm/m°C also ensures that it can maintain its structural integrity and dimensional stability even when exposed to extreme temperatures.

Finally, our NiCr Alloy product has an elongation of 30%, which means that it can be easily formed and shaped into a variety of configurations to meet specific application requirements. Whether you need it in wire, strip, or ribbon form, our NiCr Alloy product is available in a range of sizes and dimensions to suit your needs.

At our company, we understand the importance of quality and reliability, which is why we use only the highest-grade materials and manufacturing processes to produce our NiCr Alloy product. So whether you are looking for a dependable heating element, a high-performance resistor component, or a reliable thermocouple material, our NiCr Alloy product is the perfect choice.

Applications:

One of the most common applications for the DLX NiCr Alloy is in the manufacturing of heating elements. This product is commonly used in the production of industrial heating elements, such as those used in ovens, furnaces, and other high-temperature environments. The NiCr Alloy is also used in the production of household appliances, such as toasters and hair dryers.

The DLX NiCr Alloy is also used in the automotive industry, where it is used to manufacture exhaust systems, catalytic converters, and other high-temperature components. The NiCr Alloy is known for its exceptional strength and durability, making it an ideal choice for these demanding applications.

In addition to its use in the manufacturing of heating elements and automotive components, the DLX NiCr Alloy is also used in the production of medical equipment, such as dental implants and surgical instruments. The NiCr Alloy is known for its excellent corrosion resistance, making it an ideal choice for these applications where hygiene is of utmost importance.

The DLX NiCr Alloy is also used in the aerospace industry, where it is used to manufacture various components, including turbine blades, exhaust systems, and aircraft engine parts. The NiCr Alloy is known for its exceptional strength and thermal expansion properties, making it an ideal choice for these demanding applications.

In summary, the DLX NiCr Alloy is a versatile product that is used in a wide range of applications and scenarios. Whether you're in the automotive, aerospace, medical, or heating industry, the NiCr Alloy is an excellent choice. With its exceptional strength, corrosion resistance, and thermal expansion properties, the NiCr Alloy is a reliable and high-performing product that you can count on.

Support and Services:

Our NiCr Alloy product comes with comprehensive technical support and services to ensure optimal performance and longevity. Our team of experienced professionals is available to provide assistance and advice on all aspects of product installation, operation, maintenance, and troubleshooting. We offer on-site training and support services to help our customers get the most out of their NiCr Alloy product. In addition, we provide repair and replacement services for any defective or damaged parts, ensuring that our customers can always rely on their NiCr Alloy product to deliver the performance they need.

Packing and Shipping:

Product Packaging:

The NiCr Alloy product will be carefully packaged in a sturdy box to ensure safe delivery. The box will be labeled with the product name, quantity, and any handling instructions. The product will be securely wrapped in protective materials to prevent any damage during shipping.

Shipping:

We offer worldwide shipping for NiCr Alloy product. The shipping cost will be calculated based on the destination and the weight of the package. We use reputable shipping companies to ensure timely and safe delivery. Once the product is shipped, we will provide you with a tracking number so you can track the status of your package.

About Us:

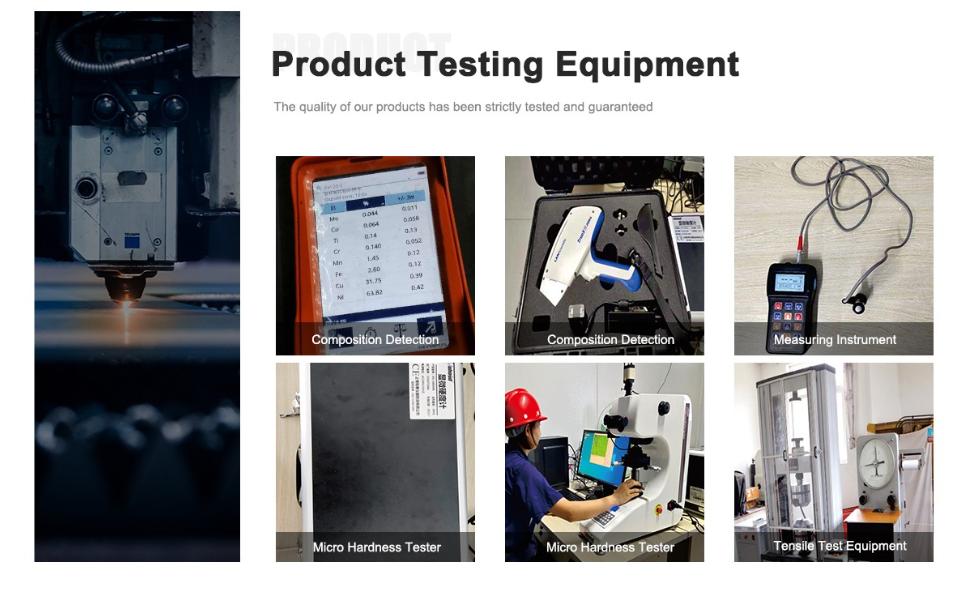

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why use NiCr alloy wire for high-temperature applications?

Its heat stability and durability make it perfect for intense heating environments.

What does HRC 40-45 hardness mean for this wire?

It ensures strong resistance to wear and deformation, ideal for tough industrial conditions.

How does the 200 GPa elasticity benefit applications?

It allows the wire to flex and recover without permanent damage, great for dynamic systems.

Can this wire handle extreme heat?

Yup, it’s stable up to 1200°C, perfect for high-temperature furnaces and heaters.

Is this NiCr wire corrosion-resistant?

Totally, it forms a protective oxide layer to fight corrosion in harsh environments.

Is this wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be shaped for custom heating elements?

Absolutely, its formability supports complex designs for specific applications.

Is this NiCr wire cost-effective?

Yes, it balances high performance with reasonable cost for industrial use.