Nichrome Alloy Wire Hardness HV400-500 Non-magnetic Properties

- Product Details

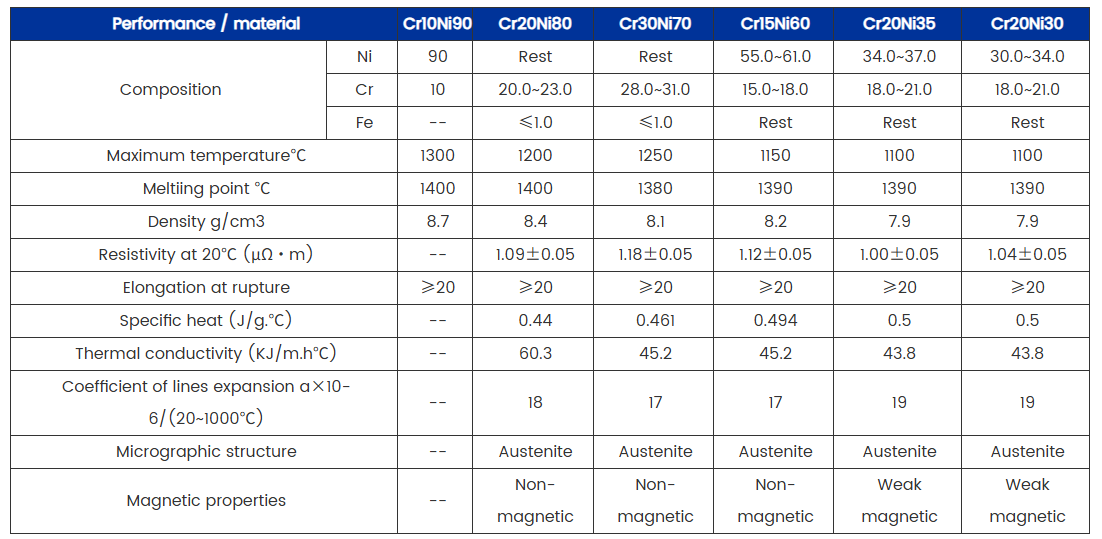

One of the key features of Nichrome Alloy is its high melting point of 1400-1450°C. This makes it highly resistant to heat and allows it to maintain its strength and durability in even the most extreme environments. In addition, the material is non-magnetic, making it suitable for use in applications where magnetic properties are a concern.

Nichrome Alloy is available in several grades, including Cr15Ni60, Cr20Ni35, Cr20Ni30, and Cr30Ni70. Each grade is designed to provide specific properties and characteristics, making it easy to find the right material for your particular needs.

One of the most impressive features of Nichrome Alloy is its excellent corrosion resistance. This makes it highly resistant to rust and other forms of degradation, even when exposed to harsh chemicals or environmental conditions. As a result, it is often used in applications where durability and longevity are critical.

In addition to its impressive corrosion resistance, Nichrome Alloy also has a thermal expansion rate of 13-17 μm/mK. This means that it can expand and contract with changes in temperature without becoming damaged or compromised.

Overall, Nichrome Alloy is a top choice for industries that require high-performance materials that can withstand extreme temperatures and harsh conditions. Whether you are looking for Nitinol, Nitinol Materials, or other high-quality alloys, Nichrome Alloy is an excellent choice that is sure to provide the performance and durability you need.

Applications:

The Nichrome Wire is widely used in various industries, such as the automotive, aerospace, medical, and electronics industries. It is ideal for manufacturing heating elements, resistors, and other electrical appliances. The product is available in four grades, namely Cr15Ni60, Cr20Ni35, Cr20Ni30, and Cr30Ni70.

The Nichrome Wire has a tensile strength of 400-500 MPa and an electrical resistivity of 1.1-1.2 μΩm, making it a reliable and long-lasting product. Its elongation of 20-30% and excellent corrosion resistance make it suitable for use in harsh environments.

Nitinol Pipe is one of the applications of Nichrome Wire. Nitinol is a shape memory alloy that is widely used in the medical industry. The Nichrome Wire is used to manufacture Nitinol Pipe, which is used in medical implants, such as stents.

In conclusion, DLX Alloy's Nichrome Wire is a versatile product that can be used in various industries. Its high-quality and reliable performance make it an ideal choice for manufacturing heating elements, resistors, and other electrical appliances. Its wide range of applications and scenarios make it a valuable resource for any industry that requires a reliable and long-lasting product.

DLX Alloy's Nichrome Wire has a supply ability of 300 tons per month, ensuring that there is always enough stock to meet the demand. The delivery time ranges from 5-21 days, depending on the location and quantity of the order. Payment terms include L/C, T/T, Western Union, and MoneyGram, providing flexibility and convenience for customers.

Customization:

With a minimum order quantity of 5, we offer two packaging options for our Resistance wire: Spool package with Carton box, Coil package with polybag. Our delivery time ranges from 5-21 days, and we accept various payment terms such as L/C, T/T, Western Union, and MoneyGram.

DLX Alloy has a supply ability of 300 tons per month, making it a reliable choice for businesses of all sizes. Our Nichrome Wire has a hardness range of HV400-500 and is available in wire form. It has a melting point of 1400-1450°C and an electrical resistivity of 1.1-1.2 μΩm.

At DLX Alloy, we understand that every business has unique requirements. That's why we offer product customization services to meet your specific needs. Whether it's a different form or size, our team of experts can work with you to create a tailored solution that fits your requirements. Contact us today to learn more about our Nitinol product customization services.

Our Nichrome alloy wire with HV400-500 hardness and non-magnetic properties is a total powerhouse, and we’re stoked to show off what it can do for high-performance industrial applications. This wire is built to deliver top-notch durability and precision where it matters most.

This Nichrome wire, a blend of 80% nickel and 20% chromium, is a beast at handling high temperatures—up to 1200°C without breaking a sweat. Its HV400-500 hardness makes it super tough, resisting wear and deformation even in high-stress environments like industrial furnaces or precision heating systems. The non-magnetic properties are a big deal, minimizing electromagnetic interference, which is perfect for sensitive applications like sensors, medical devices, or aerospace electronics.

With a steady electrical resistivity of ~1.09 µΩ·m, it delivers consistent heat output, and its corrosion resistance is killer, forming a protective oxide layer that keeps it strong in harsh conditions. The tensile strength, around 650 MPa, ensures it lasts for years, cutting down on maintenance costs. We can shape it into coils, strips, or custom elements, making it super versatile for all kinds of manufacturing needs.

The industry in 2025 is all about precision and sustainability, and our Nichrome wire is right on trend. There’s a huge demand for non-magnetic, durable materials in electronics, aerospace, and medical sectors, where interference-free performance is critical. Being 100% recyclable, it’s a great fit for eco-conscious manufacturing. As high-precision heating and automation systems keep growing, this wire’s hardness and non-magnetic properties make it a top choice for cutting-edge applications.

Sure, FeCrAl alloys like Kanthal A-1 can push slightly higher temperatures, but our Nichrome wire’s hardness and non-magnetic nature give it an edge in precision and high-stress environments. CuNi44 Constantan is cheaper but lacks the heat resistance and durability of Nichrome. Just avoid extreme reducing atmospheres, though this wire handles most conditions like a champ.

From aerospace sensors to medical heating elements, our Nichrome alloy wire with HV400-500 hardness and non-magnetic properties brings the durability, precision, and heat performance that keep industries running smoothly and innovating.

About Us:

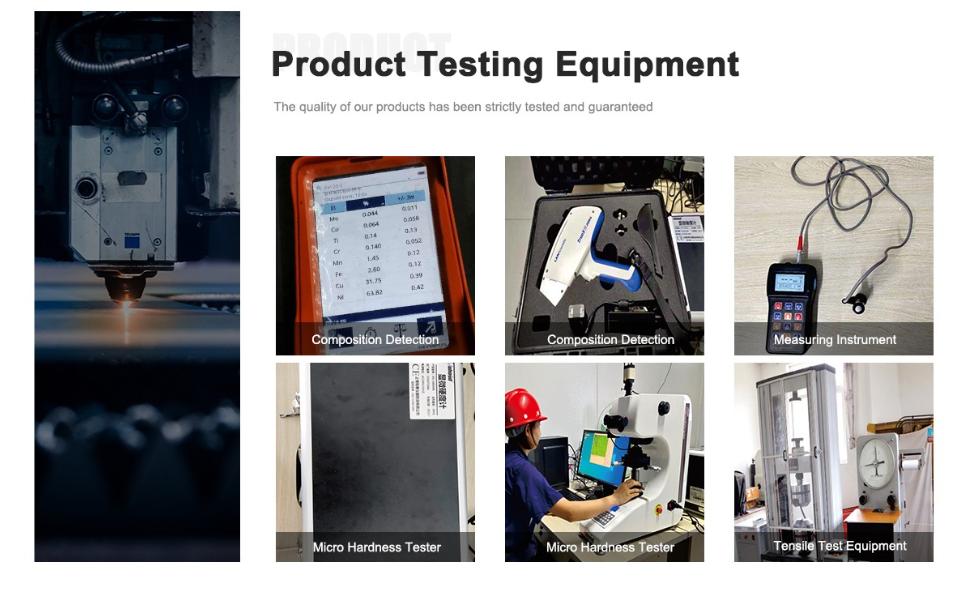

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why use Nichrome alloy wire with HV400-500 hardness for industrial applications?

Its high hardness ensures durability and wear resistance in tough environments.

What’s the benefit of its non-magnetic properties?

It minimizes electromagnetic interference, perfect for sensitive electronics and sensors.

Can this wire handle high temperatures?

Yup, it’s stable up to 1200°C, great for intense heating applications.

Is this Nichrome wire corrosion-resistant?

Totally, it forms a protective oxide layer to fight corrosion in harsh conditions.

How does this wire compare to standard Nichrome?

The HV400-500 hardness and non-magnetic properties make it ideal for specialized, high-stress uses.

Is this wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be used in precision heating systems?

Absolutely, its non-magnetic nature and stable resistivity are perfect for precise applications.

Is this Nichrome wire cost-effective?

Yes, its durability and performance balance the cost for high-value industrial uses.