Nitinol Wire with Superior Thermal Expansion and Magnetic Characteristics

- Product Details

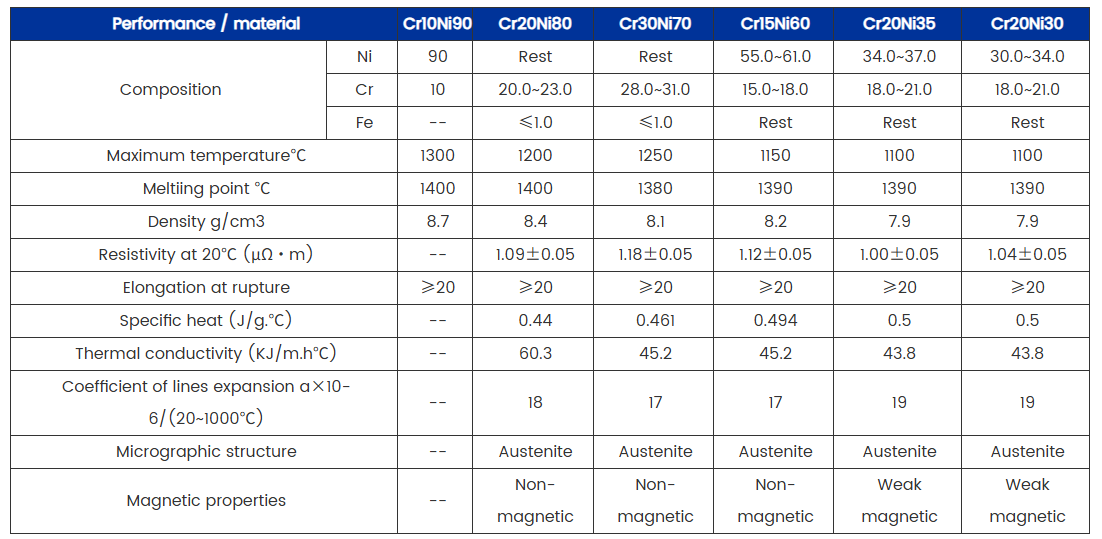

One of the essential properties of Nichrome Alloy is its high electrical resistivity, ranging from 1.1-1.2 μΩm. This attribute means that it can resist the flow of electric current, making it an excellent choice for electrical heating applications. The alloy is also highly durable, with a yield strength of 200-300 MPa, making it resistant to deformation and damage.

Another significant advantage of Nichrome Alloy is its excellent corrosion resistance, making it a popular choice for use in harsh environments. This property is essential in applications where the alloy is exposed to chemicals, moisture, and other corrosive substances. Nichrome Alloy can withstand the corrosive effects of acids, bases, and alkaline solutions, making it an ideal material for use in chemical and food processing industries.

Nitinol is another popular material used in various industries, including medical devices, aerospace, and automotive applications. Nitinol is a nickel-titanium alloy with unique shape memory and superelasticity properties. The alloy can return to its original shape when heated, making it an ideal material for use in medical implants, stents, and other devices.

Nitinol Pipe is a popular application of Nitinol materials. These pipes are used in various industries for their unique properties, including excellent corrosion resistance, high strength, and durability. Nitinol Pipe is an ideal choice for use in harsh environments, including oil and gas applications, chemical processing, and marine applications.

In conclusion, Nichrome Alloy is a highly versatile and robust material that is used in various industrial applications, including heating elements, furnaces, and electrical components. Its high electrical resistivity, yield strength, and excellent corrosion resistance make it an ideal choice for use in harsh environments. Nitinol is another popular material used in various industries, including medical devices, aerospace, and automotive applications. Nitinol Pipe is a popular application of Nitinol materials and is ideal for use in harsh environments where high strength, corrosion resistance, and durability are required.

We’re thrilled about our Nitinol wire, a nickel-titanium alloy that’s a total rockstar for applications needing superior thermal expansion and magnetic characteristics. This wire, with its shape memory effect and superelasticity, is a game-changer for industries like medical, aerospace, and oven manufacturing.

Nitinol, made of roughly equal parts nickel and titanium (around 55% Ni, 45% Ti), can “remember” its original shape, snapping back after deformation when heated above its transformation temperature (typically 30-130°C). It’s superelastic, stretching up to 10-30 times more than regular metals without permanent damage, which is perfect for dynamic applications like stents or actuators. Its thermal expansion (6.6-11 µm/m·K) is tightly controlled, ensuring stability in high-heat environments like ovens, while its low magnetic susceptibility (2.5-3.8 emu/g) minimizes interference in sensitive electronics. With tensile strength ranging from 895 to 1900 MPa and excellent corrosion resistance, this wire is built to last, even in tough conditions.

Packing and Shipping:

Product Packaging:

The Nichrome Alloy product will be packaged in a sturdy, cardboard box to ensure safe transport.

The box will be labeled with the product name, quantity, and any other relevant information.

Inside the box, the product will be wrapped in bubble wrap or other protective materials to prevent damage during shipping.

Shipping:

The Nichrome Alloy product will be shipped via a reputable courier service.

Shipping options include standard or expedited delivery, depending on the customer's needs.

The customer will receive a tracking number once the product has been shipped.

Shipping costs will be calculated based on the customer's location and the selected delivery method.

About Us:

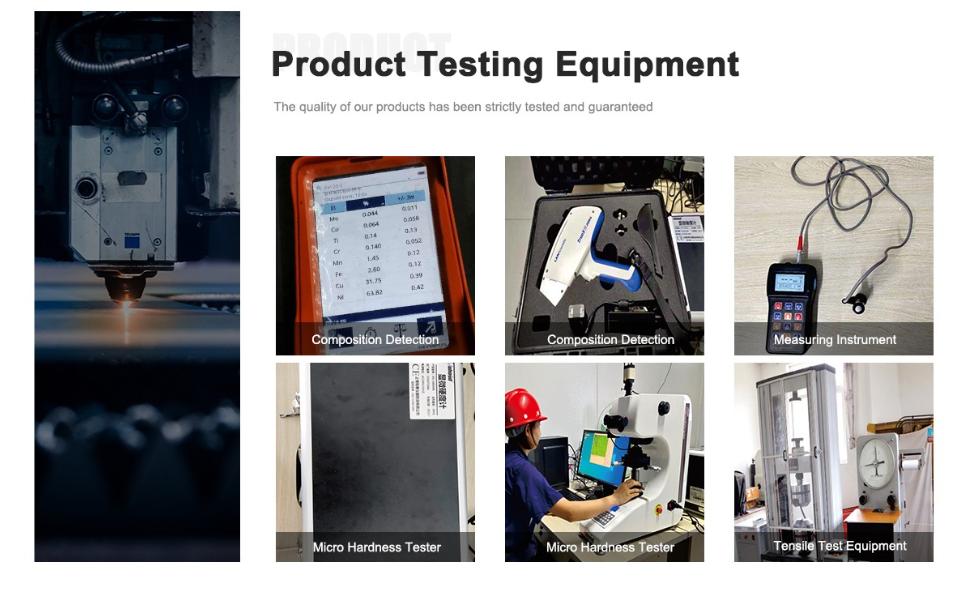

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

Why use Nitinol wire for high-performance applications?

Its shape memory and superelasticity make it ideal for dynamic, flexible systems.

How does Nitinol’s thermal expansion benefit oven applications?

Its controlled expansion ensures stability under temperature changes, perfect for precise heating.

What makes Nitinol’s magnetic properties special?

Low magnetic susceptibility minimizes interference, great for sensitive electronics.

Can Nitinol wire handle high temperatures?

Yup, it’s stable up to 500°C in most applications, with excellent shape recovery.

Is Nitinol wire corrosion-resistant?

Totally, it resists corrosion even in harsh environments, ensuring long-term reliability.

Is Nitinol wire recyclable?

100% recyclable, fitting eco-friendly manufacturing trends.

Can it be used in medical devices?

Absolutely, its biocompatibility and flexibility are perfect for stents and implants.

Is Nitinol wire cost-effective for industrial use?

Yes, its durability and unique properties balance cost for high-value applications.