Stranded Twisted Nichrome Ni80Cr20 Resistance Alloy Wire for Resistance

- Product Details

Product Details

Place Of Origin: China

Brand Name: DLX

Model Number: Cr20Ni80

Payment & Shipping Terms

Minimum Order Quantity: 5

Packaging Details: Spool Package With Carton Box, Coil Package With Polybag For Resistance Wire

Delivery Time: 5-21 Days

Payment Terms: L/C, T/T, Western Union, MoneyGram

Supply Ability: 300 Tons Per Month

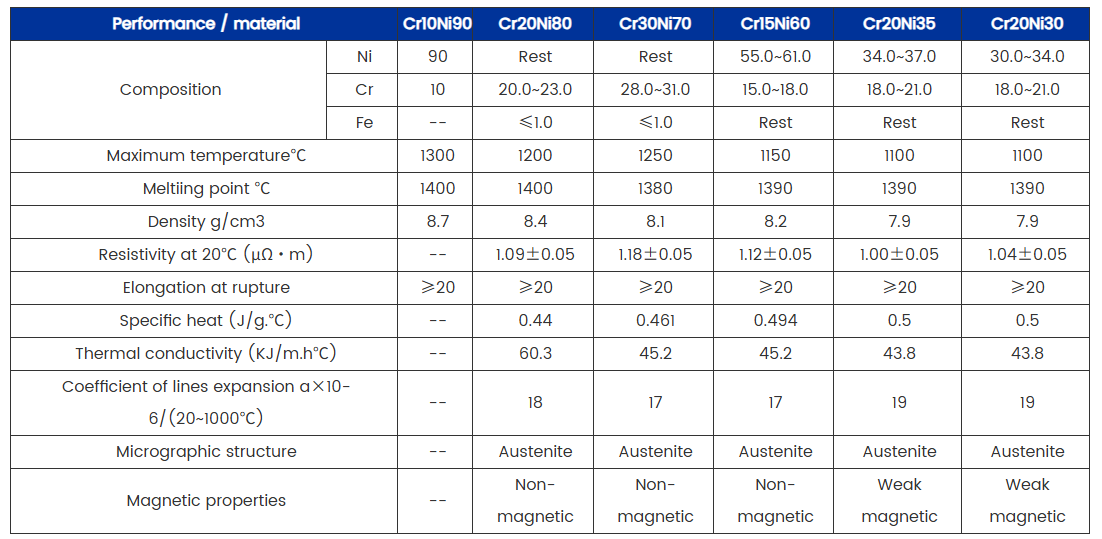

Cr20Ni80 wire, also known as Nichrome 80/20 wire, is an alloy made from 80% nickel and 20% chromium. It is widely used in various industrial applications due to its high resistance to oxidation and corrosion, along with its ability to withstand high temperatures. This alloy wire is commonly utilized in heating elements, resistance wire, and other high-temperature applications.

Highlight: Heating Element Cr20Ni80 Resistance Wire, Heating Element Nichrome 80 Resistance Wire, 637MPA NiCr Alloy

We’re totally jazzed about our stranded twisted Nichrome Ni80Cr20 resistance alloy wire—it’s a powerhouse for resistance applications, blending durability with a clever design that’s perfect for all sorts of industries. This wire is built to deliver consistent performance where it counts.

Ni80Cr20, with its 80% nickel and 20% chromium mix, is a beast at handling high temperatures—up to 1200°C without breaking a sweat. Its oxidation resistance is top-notch, forming a protective layer that keeps corrosion at bay, even in harsh industrial environments. The stranded twisted design is the real star here, giving it extra flexibility and strength compared to solid wires. That makes it ideal for complex setups like precision resistors, industrial heaters, or even dynamic systems where movement is a factor. With a steady electrical resistivity of about 1.09 µΩ·m, it ensures reliable, consistent performance.

The tensile strength, around 650 MPa, means this wire is tough enough to last for years, cutting down on maintenance hassles. Its stranded structure also makes it super easy to work with—we can shape it into intricate coils or custom configurations to fit any resistance application, from small-scale electronics to heavy-duty industrial systems.

The industry in 2025 is all about precision, efficiency, and sustainability, and our Ni80Cr20 wire is right on point. There’s a big demand for materials that can handle high heat while staying flexible for advanced designs, especially in electronics, automotive, and renewable energy sectors. Being 100% recyclable, it’s a perfect fit for eco-conscious manufacturing trends. The stranded design also aligns with the push for durable, adaptable components in automated and high-precision systems.

Sure, FeCrAl alloys like Kanthal A-1 can push slightly higher temperatures, but our Ni80Cr20’s oxidation resistance and flexibility make it a go-to for most resistance applications, especially where intricate or dynamic designs are needed. Just steer clear of extreme reducing atmospheres, though it handles most conditions like a pro.

From precision resistors to industrial heating systems, our stranded twisted Nichrome Ni80Cr20 wire is the reliable, flexible solution that keeps industries powered up and running smoothly.

High-Temperature Resistance:

Can withstand temperatures up to 1200°C (2192°F) in continuous service, making it ideal for use in high-temperature environments such as furnaces, kilns, and heaters.

Oxidation and Corrosion Resistance:

Exhibits excellent resistance to oxidation in both hot and cold environments, due to the formation of a protective chromium oxide layer.

Resists corrosion in various atmospheric conditions, including moist or humid environments, which extends the lifespan of the wire in demanding settings.

Electrical Resistivity:

Cr20Ni80 has a high electrical resistivity, around 1.09 µΩ·m at 20°C, making it ideal for use in resistance heating applications. The resistivity remains stable over a wide temperature range, ensuring consistent performance.

Mechanical Strength and Stability:

The wire has excellent mechanical strength at elevated temperatures, making it resistant to sagging, warping, or deformation under continuous high heat.

It also maintains good ductility, allowing it to be shaped, bent, or coiled without losing its structural integrity.

Thermal Expansion:

Exhibits moderate thermal expansion, ensuring that it does not expand or contract significantly when exposed to temperature fluctuations, which is critical for precise heating elements and applications.

Key Advantages of Cr20Ni80 Wire:

Consistent Resistance: Offers stable and predictable resistance across a wide range of temperatures.

Durability: Long lifespan due to its resistance to oxidation, corrosion, and thermal fatigue.

High Melting Point: Can handle extremely high temperatures without melting or degrading, making it suitable for demanding thermal applications.

Versatile: Used in a wide range of industries, including manufacturing, electronics, and laboratory environments.

Comparison to Other Alloys:

Compared to lower nickel-chromium alloys (like Cr15Ni60), Cr20Ni80 has better resistance to oxidation, a higher working temperature limit, and greater stability under high-heat conditions.

While more expensive than some alternatives, its longer lifespan and superior performance make it cost-effective in the long run for applications where reliability is crucial.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why use stranded twisted Ni80Cr20 wire for resistance applications?

Its high heat resistance and stranded design make it super reliable and flexible for various setups.

How does Ni80Cr20 compare to FeCrAl alloys?

Ni80Cr20 offers better oxidation resistance, while FeCrAl handles slightly higher temperatures.

Can this wire handle continuous high heat?

Yup, it’s stable up to 1200°C, perfect for demanding resistance applications.

What’s the benefit of the stranded twisted design?

It adds flexibility and strength, ideal for complex or dynamic resistance setups.

Is Ni80Cr20 wire resistant to corrosion?

Totally, it forms a protective oxide layer to fight corrosion in tough environments.

Is this wire recyclable?

100% recyclable, aligning with sustainable manufacturing trends.

Can it be used in precision resistors?

Absolutely, its consistent resistivity makes it great for high-precision applications.

Is Ni80Cr20 wire cost-effective for resistance use?

Yes, it balances top performance with a reasonable price for industrial needs.