Nichrome Alloy Wire The Trusted and Durable Heating Solution for Industries

- Product Details

We’re stoked about our Nichrome alloy wire—it’s the trusted, durable heating solution industries rely on to keep things hot and efficient. This wire is a total rockstar for applications where consistent heat and long-lasting performance are a must.

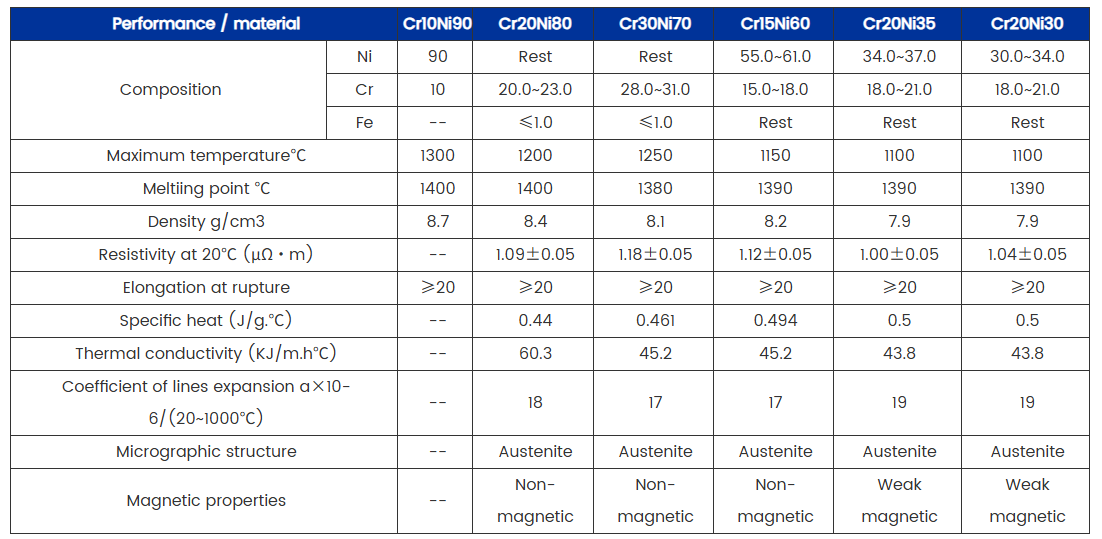

Nichrome, a nickel-chromium alloy (typically 80% nickel, 20% chromium), is built to handle crazy high temperatures—up to 1200°C without breaking a sweat. Its oxidation resistance is top-notch, forming a protective layer that shrugs off corrosion, even in harsh industrial environments. Whether it’s furnaces, kilns, or heat-treating systems, this wire keeps the heat steady with an electrical resistivity of about 1.09 µΩ·m, ensuring reliable performance every time.

With a tensile strength around 650 MPa, Nichrome wire is tough as nails, lasting years with minimal maintenance. It’s also super versatile—we can coil it, bend it, or customize it into any heating element design you need, from industrial ovens to aerospace heaters. That kind of flexibility makes it a favorite for manufacturers.

The industry in 2025 is all about efficiency, durability, and sustainability, and our Nichrome wire checks every box. There’s a big push for materials that can handle high heat while cutting down on replacements, especially in sectors like steel, ceramics, and electronics. Being 100% recyclable, it’s a perfect fit for the growing trend of eco-conscious production. Plus, as automated and precision heating systems take off, Nichrome’s consistent resistivity makes it a go-to choice.

Sure, FeCrAl alloys like Kanthal A-1 can hit slightly higher temps, but Nichrome’s oxidation resistance and versatility make it a sweet spot for most industrial heating jobs. Just watch out for extreme reducing atmospheres, though this wire handles most conditions like a champ.

From massive industrial furnaces to specialized heating systems, our Nichrome alloy wire delivers the heat, durability, and reliability that keep industries running smoothly.

Product Description:

One of the main applications of Nichrome Alloy is in the manufacturing of Nichrome coil, which is widely used in the heating industry. Nichrome coil is made of Cr20Ni80, a type of Nichrome Alloy that contains 20% chromium and 80% nickel. This alloy has a melting point of 1400°C and a maximum operating temperature of 1200°C. In addition, it has a high yield strength of 200-300 MPa and a density of 8.4 G/cm3.

The Nichrome Alloy is also used in the production of furnaces and electrical components. Thanks to its excellent high-temperature properties, it can withstand temperatures of up to 1200°C without losing its mechanical strength. This makes it an ideal material for use in high-temperature applications.

Another advantage of Nichrome Alloy is its resistance to oxidation and high-temperature corrosion. This property makes it an ideal material for use in harsh environments where other materials would quickly degrade. Nichrome Alloy can withstand exposure to high temperatures and corrosive agents without being damaged, which makes it a popular choice for many industrial applications.

In summary, the Nichrome Alloy is a high-quality material that is widely used in the manufacturing of Nichrome coil, furnaces, and electrical components. It has excellent high-temperature properties, a high yield strength, and a density of 8.4 G/cm3. Its non-magnetic properties make it an ideal material for use in many industrial applications.

Customization:

Customers can choose from two packaging options for resistance wire: spool package with carton box or coil package with polybag. The delivery time for this product ranges from 5-21 days, and payment can be made through L/C, T/T, Western Union, or MoneyGram. The supply ability for this product is 300 tons per month.

One of the best properties of Nichrome is its excellent corrosion resistance and thermal conductivity of 15-20 W/mK. The chemical composition of this product is Ni-Cr-Fe, making it a reliable and durable option for heating elements. Contact DLX Alloy to learn more about their customization services for Nichrome wire, coil, and other forms.

Support and Services:

Our Nichrome Alloy product is backed by our technical support and services team, who are available to assist you with any questions or issues you may have. Our experts can provide guidance on product selection, installation, operation, and maintenance to ensure the optimal performance and longevity of your Nichrome Alloy product. In addition, we offer repair and replacement services for any defective or damaged products. Contact us for more information on how we can support your needs.

About Us:

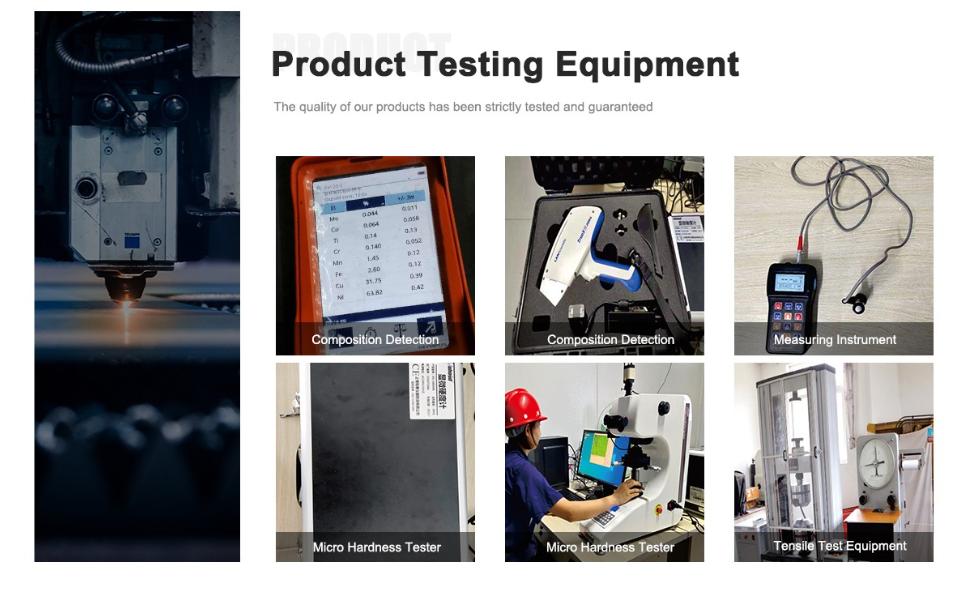

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why is Nichrome alloy wire a go-to for industrial heating?

Its ability to handle high temperatures and resist oxidation makes it super reliable for industrial systems.

How does Nichrome compare to FeCrAl alloys like Kanthal?

Nichrome has better oxidation resistance, while FeCrAl can push slightly higher temperatures.

Can Nichrome alloy wire handle continuous high heat?

Totally, it’s stable up to 1200°C for most industrial heating needs.

Is Nichrome wire resistant to corrosion?

Yup, it forms a protective oxide layer that fights corrosion in tough environments.

How long does Nichrome wire last in industrial use?

It’s built to last for years with minimal maintenance, saving downtime and costs.

Is Nichrome alloy wire recyclable?

100% recyclable, perfect for eco-friendly manufacturing goals.

Can Nichrome wire be customized for specific heating designs?

Absolutely, it’s easy to shape into coils or custom elements for any setup.

Is Nichrome wire cost-effective for industries?

Definitely, it delivers top performance without a crazy price tag.