Industrial Applications of Nichrome Electric Heating Resistance Alloy-Cr20Ni80

- Product Details

Products Description

80/20 Ni Cr Resistance Wire of DLX Alloy is an alloy used at operating temperatures up to 1200°C (2200°F). 80/20 Ni Cr Resistance Wire is also known as Nichrome / Nicrhrome V, Brightray C, Cronix 80, Nicrothal 80, Chromalloy, Chromel, and Gilphy 80. Its chemical composition gives good oxidation resistance, especially under conditions of frequent switching or wide temperature fluctuations. This makes it ideal for a wide variety of applications including heating elements in domestic and industrial appliances, wire-wound resistors, through to the aerospace industry.

We’re super excited about our Cr20Ni80 Nichrome alloy for industrial electric heating—it’s the kind of material that keeps furnaces, kilns, and heaters running like champs. This alloy is a powerhouse for applications where high heat and reliability are non-negotiable.

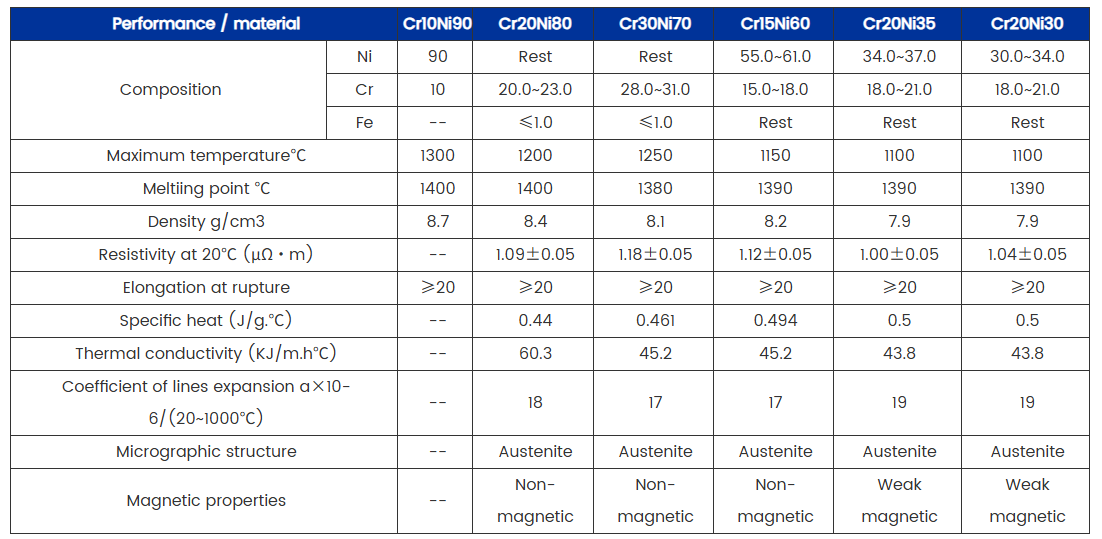

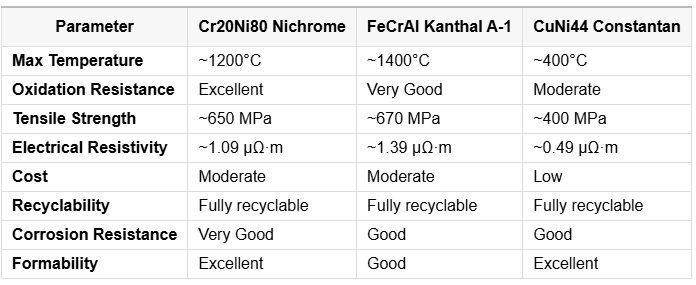

Cr20Ni80, with its 80% nickel and 20% chromium mix, is built to handle serious heat—up to 1200°C without breaking a sweat. It’s got awesome oxidation resistance, forming a protective layer that laughs off corrosive atmospheres, making it perfect for tough industrial environments. Whether it’s heat-treating furnaces, ceramic kilns, or industrial ovens, this alloy delivers consistent performance. Its electrical resistivity, around 1.09 µΩ·m, stays steady, ensuring even heating every time.

With a tensile strength of about 650 MPa, Cr20Ni80 is tough enough to last for years, cutting down on maintenance and replacements. It’s also super versatile—we can shape it into coils, strips, or custom heating elements to fit any industrial setup. That kind of flexibility is a big deal for manufacturers needing tailored solutions.

The industry’s buzzing with trends toward efficiency and sustainability, and Cr20Ni80 is right in the sweet spot. There’s a growing demand for materials that can handle high temperatures while lasting longer, especially in sectors like metal processing, glass manufacturing, and aerospace. Since it’s fully recyclable, it’s a great fit for companies pushing green production. Plus, as automation and precision heating systems become more common, this alloy’s stable performance makes it a top pick.

Sure, FeCrAl alloys like Kanthal can push slightly higher temperatures, but Cr20Ni80’s oxidation resistance and cost-effectiveness make it a go-to for most industrial heating needs. Just make sure your setup avoids extreme reducing atmospheres, though this alloy handles most conditions like a pro.

From massive industrial furnaces to specialized heat treatment systems, our Cr20Ni80 Nichrome alloy keeps the heat on, delivering the reliability and performance industries depend on.

About Us:

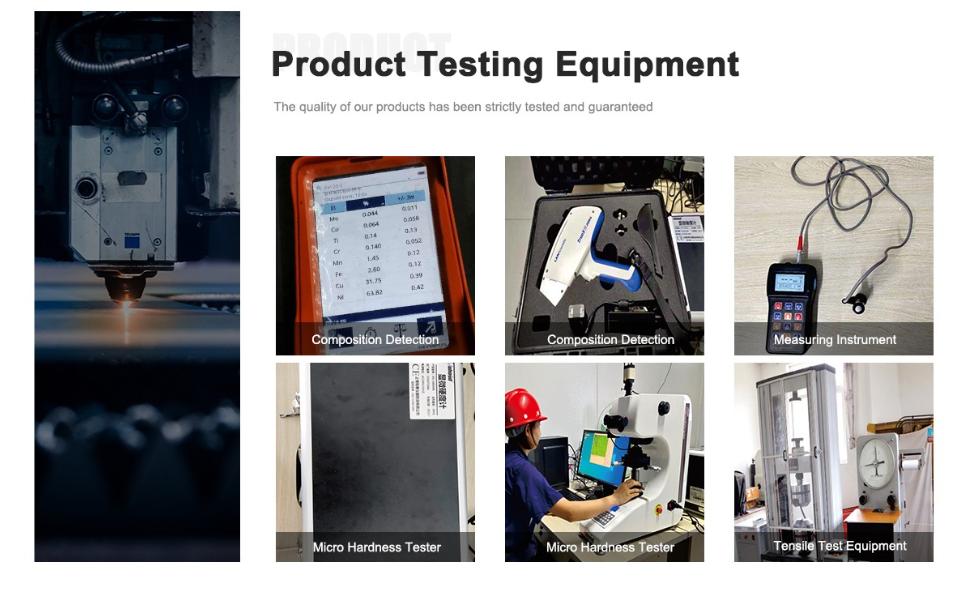

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why is Cr20Ni80 Nichrome used in industrial heating?

Its ability to handle high temperatures and resist oxidation makes it perfect for heavy-duty heating systems.

How does Cr20Ni80 compare to FeCrAl alloys?

Cr20Ni80 has better oxidation resistance, while FeCrAl can tolerate slightly higher temperatures.

Can Cr20Ni80 withstand continuous high-heat environments?

Totally, it’s stable up to 1200°C for most industrial heating applications.

Is Cr20Ni80 suitable for corrosive atmospheres?

Yes, it forms a protective oxide layer that fights off corrosion in oxidizing conditions.

How durable is Cr20Ni80 in industrial settings?

Super durable—it can last years with proper maintenance, reducing replacement costs.

Is Cr20Ni80 recyclable?

Yup, it’s 100% recyclable, supporting eco-friendly industrial practices.

Can Cr20Ni80 be shaped for custom heating elements?

Absolutely, its formability makes it easy to tailor for specific designs.

Is Cr20Ni80 cost-effective for industrial use?

Definitely, it offers a great balance of performance and price for heating applications.