Thermal Conductive Nichrome Alloy Wire with 13-17 µm/mK Thermal Expansion and 20-30% Elongation

- Product Details

We’re stoked about our thermal conductive Nichrome alloy wire, designed with a 13-17 µm/mK thermal expansion and 20-30% elongation—perfect for industrial heating applications that need efficiency and flexibility. This wire is a total workhorse, ready to tackle demanding thermal environments.

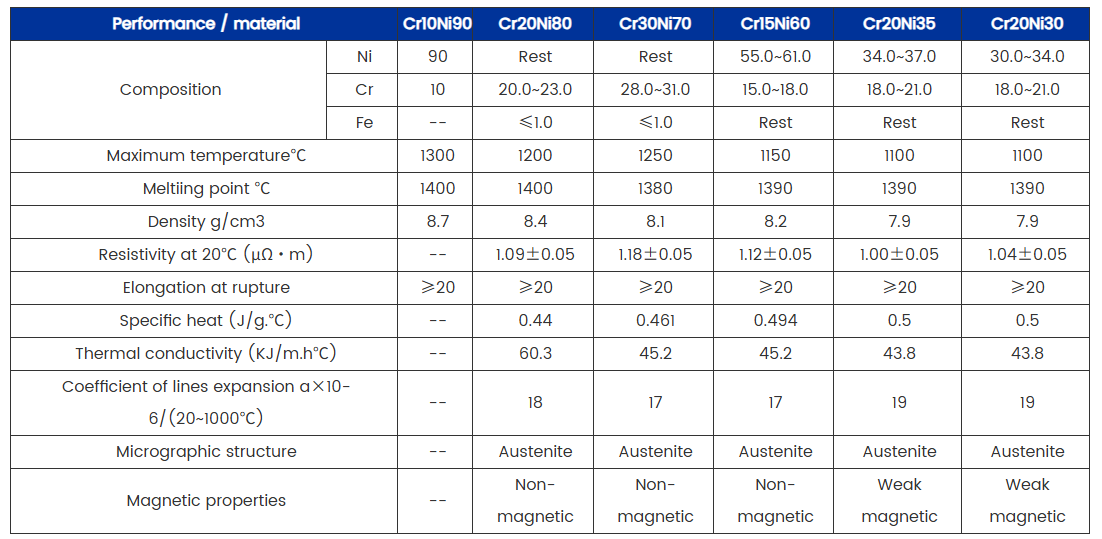

This Nichrome alloy, a nickel-chromium blend, rocks high thermal conductivity (13-15 W/mK), making it a champ at transferring heat evenly. It’s built to handle temperatures up to 1150°C, and its excellent oxidation resistance means it forms a protective layer to fend off corrosion, even in tough industrial settings. The 13-17 µm/mK thermal expansion keeps it dimensionally stable, so it won’t warp or crack when the heat’s on. Plus, with 20-30% elongation, this wire is super flexible, letting us shape it into intricate coils or custom heating elements without worrying about breakage.

The electrical resistivity, around 1.05 µΩ·m, stays consistent, ensuring steady performance in furnaces, ovens, or specialized heating systems. Its durability means you’re looking at years of reliable use with minimal maintenance, which is a big win for manufacturers.

The industry in 2025 is all about efficiency and sustainability, and this wire fits right in. There’s a huge push for materials that deliver high thermal performance while keeping costs down, especially in sectors like ceramics, metal processing, and electronics. The 20-30% elongation makes it ideal for complex designs in automated, high-precision heating systems. Being 100% recyclable, it’s also a great match for eco-conscious production trends driving the market.

Sure, FeCrAl alloys like Kanthal A-1 can hit higher temperatures, but our Nichrome wire’s thermal conductivity and flexibility give it an edge for applications needing precise heat transfer and formability. Just make sure your setup avoids extreme reducing atmospheres, though this wire handles most conditions like a pro.

From industrial kilns to high-tech heating elements, our thermal conductive Nichrome alloy wire is built to deliver reliable, efficient heat with the flexibility to meet any design challenge.

Advantages of Thermal Conductive Nichrome Alloy Wire with 13-17 µm/mK Thermal Expansion and 20-30% Elongation

High thermal conductivity

Excellent oxidation resistance

Optimal thermal expansion range

Superior elongation for flexibility

Reliable electrical resistivity

Features:

Product Name: Nichrome Alloy

Tensile Strength: 400-500 MPa

Forms: Wire, Sheet, Strip, Rod, Tube

Electrical Resistivity: 1.1-1.2 μΩm

Chemical Composition: Ni-Cr-Fe

Elongation: 20-30%

Our Nichrome Alloy product, also known as Cr20Ni80, is a high strength alloy with a tensile strength of 400-500 MPa. It comes in various forms including wire, sheet, strip, rod, and tube. With an electrical resistivity of 1.1-1.2 μΩm and a chemical composition of Ni-Cr-Fe, this alloy is perfect for creating Nichrome coils. It also has an elongation of 20-30%, making it a versatile and durable material for various applications.

Support and Services:

The Nichrome Alloy is a high-resistance alloy made of nickel, chromium, and sometimes iron. It is commonly used in heating elements, furnace components, and electrical appliances. Our product technical support and services for Nichrome Alloy include:

Expert advice on material selection, design, and processing

Customized alloy composition and manufacturing

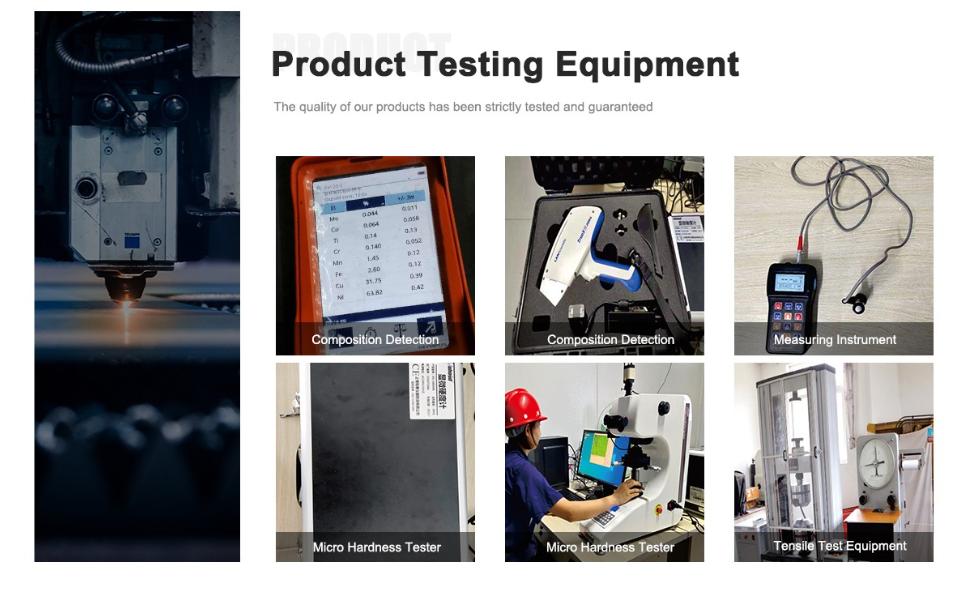

Testing and analysis of physical and mechanical properties

Technical documentation and material certification

On-site technical support and troubleshooting

Training and education on proper handling, installation, and maintenance

Our team of specialists is dedicated to providing the highest level of technical support and services to help you achieve optimal performance and efficiency with your Nichrome Alloy applications.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.