Ultra Low Resistivity Nichrome Sheet Wire for Electrical Applications

- Product Details

We’re pumped about our ultra low resistivity Nichrome sheet wire—it’s a total game-changer for electrical applications where efficiency and reliability are everything. This wire is designed to deliver top-notch performance in systems that need precise power delivery without wasting energy.

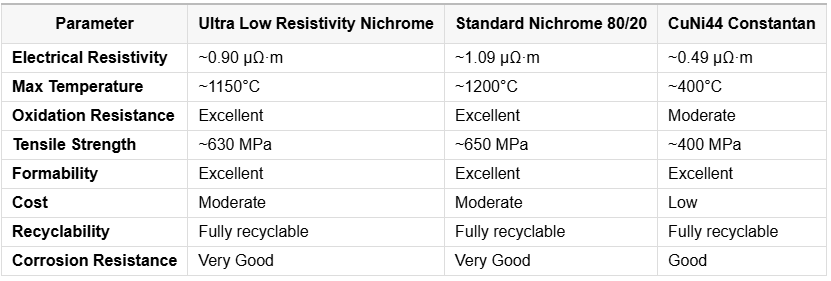

This Nichrome alloy, a nickel-chromium blend with tweaked composition for ultra low resistivity (around 0.90 µΩ·m), is perfect for applications where every bit of conductivity counts. It still holds up in high heat—stable up to 1150°C—and its excellent oxidation resistance means it forms a protective layer to fend off corrosion, even in tough environments. Whether it’s for resistors, Heating Element s, or precision circuits, this wire keeps things running smoothly.

The tensile strength, around 630 MPa, makes it super durable, so you’re not swapping it out every other month. Plus, its formability is a big win—we can roll it into thin sheets or shape it into custom designs for all kinds of electrical setups. From industrial control systems to high-precision electronics, this wire’s got the flexibility to fit right in.

The electrical industry in 2025 is all about efficiency and sustainability, and our ultra low resistivity Nichrome wire is right on trend. There’s a huge demand for materials that maximize conductivity while keeping costs reasonable, especially in electronics, automotive, and renewable energy systems. Its recyclability—100% recyclable—makes it a great fit for eco-conscious production. As precision electronics and smart systems keep growing, this wire’s low resistivity and reliability make it a top pick.

Sure, standard Nichrome 80/20 might handle slightly higher temperatures, but our ultra low resistivity version shines where conductivity is key. Just keep it away from extreme reducing atmospheres, though it handles most conditions like a champ.

From circuit boards to industrial heating elements, our ultra low resistivity Nichrome sheet wire is built to power up your electrical applications with efficiency, durability, and precision.

Product Description:

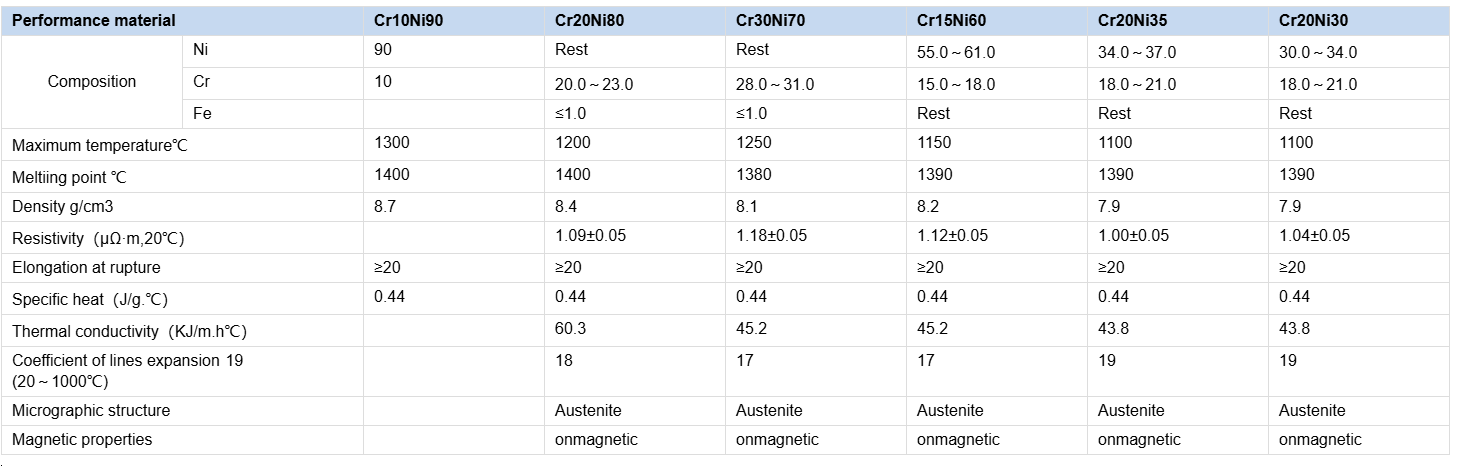

The Nichrome Alloy has an elongation of 20-30% which means it can stretch up to 30% of its original length before breaking. This property makes it an ideal material for use in nichrome heating elements, as it can withstand high temperatures and can be bent into various shapes and sizes without breaking. Additionally, the Nichrome Alloy has a yield strength of 200-300 MPa, which means it can withstand a considerable amount of tension without breaking or deforming.

The Nichrome Alloy has excellent thermal conductivity, with a thermal conductivity rating of 15-20 W/mK. This attribute makes it an ideal material for use in nichrome coil, which is used in heating applications such as furnaces, ovens, and resistive heating elements. The Nichrome Alloy can quickly and efficiently transfer heat, making it an excellent choice for applications that require high temperatures.

The Nichrome Alloy has a thermal expansion rate of 13-17 μm/mK. This attribute means that the Nichrome Alloy can expand and contract as temperatures change without becoming deformed or damaged. This property makes it an ideal material for use in nichrome heating elements, as it can withstand the constant changes in temperature without breaking or becoming damaged.

The Nichrome Alloy has excellent corrosion resistance, making it an ideal material for use in harsh environments. This attribute makes it an excellent choice for applications that require resistance to corrosion and oxidation, such as in chemical processing plants and marine applications. The Nichrome Alloy can withstand exposure to harsh chemicals and saltwater without becoming damaged or corroded.

In conclusion, the Nichrome Alloy is a reliable and versatile material that is widely used in various industries. Its exceptional properties such as excellent thermal conductivity, high elongation, excellent corrosion resistance, and its ability to expand and contract without becoming damaged make it an ideal material for use in nichrome wire, nichrome heating elements, and nichrome coil.

Features:

Product Name: Nichrome Alloy

Applications: Heating Elements, Furnaces, Electrical Components

Melting Point: 1400-1450°C

Hardness: HV400-500

Thermal Conductivity: 15-20 W/mK

Tensile Strength: 400-500 MPa

Some common uses for Nichrome Alloy include:

Nichrome wire for heating elements

Nichrome heating elements for furnaces

Nichrome Alloy in electrical components

Technical Parameters:

| Melting Point | 1400-1450°C |

| Forms | Wire, Sheet, Strip, Rod, Tube |

| Electrical Resistivity | 1.1-1.2 μΩm |

| Chemical Composition | Ni-Cr-Fe |

| Tensile Strength | 400-500 MPa |

| Magnetic Properties | Non-magnetic |

| Yield Strength | 200-300 MPa |

| Thermal Expansion | 13-17 μm/mK |

| Density | 8.4 G/cm3 |

| Applications | Heating Elements, Furnaces, Electrical Components |

Packing and Shipping:

Product Packaging:

The Nichrome Alloy product will be carefully packaged to ensure its safe delivery to your doorstep. It will be packed in a sturdy cardboard box with sufficient cushioning material to prevent any damage during transit.

Shipping:

We offer worldwide shipping of our Nichrome Alloy product. Shipping costs will vary based on the shipping destination and the weight of the package. We use reliable shipping carriers to ensure that your order is delivered safely and on time.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

Why use ultra low resistivity Nichrome sheet wire for electrical applications?

Its low resistivity ensures efficient power delivery, perfect for precision electrical systems.

How does this Nichrome wire compare to standard Nichrome alloys?

It has lower resistivity for better conductivity, while retaining similar heat and corrosion resistance.

Can this wire handle high temperatures?

Yup, it’s stable up to 1150°C, great for demanding electrical setups.

Is the wire resistant to oxidation in electrical systems?

Totally, it forms a protective oxide layer to fend off corrosion.

How formable is this Nichrome sheet wire?

Super formable, making it easy to shape into thin sheets or custom designs.

Is this wire recyclable?

100% recyclable, aligning with sustainable manufacturing trends.

Can it be used in precision electronics?

Absolutely, its ultra low resistivity makes it ideal for high-precision circuits.

Is this wire cost-effective for electrical applications?

Yes, it balances top performance with reasonable costs for industrial use.