0Cr25AI5 FeCrAl Wire The Perfect Heating Wire for High-Temperature Applications

- Product Details

Our 0Cr25Al5 FeCrAl wire is a total beast for high-temperature heating applications, and we’re pumped to share why it’s the perfect choice for industries pushing the limits of heat. This iron-chromium-aluminum alloy is built to deliver rock-solid performance in the hottest, toughest environments, from industrial furnaces to precision heating systems.

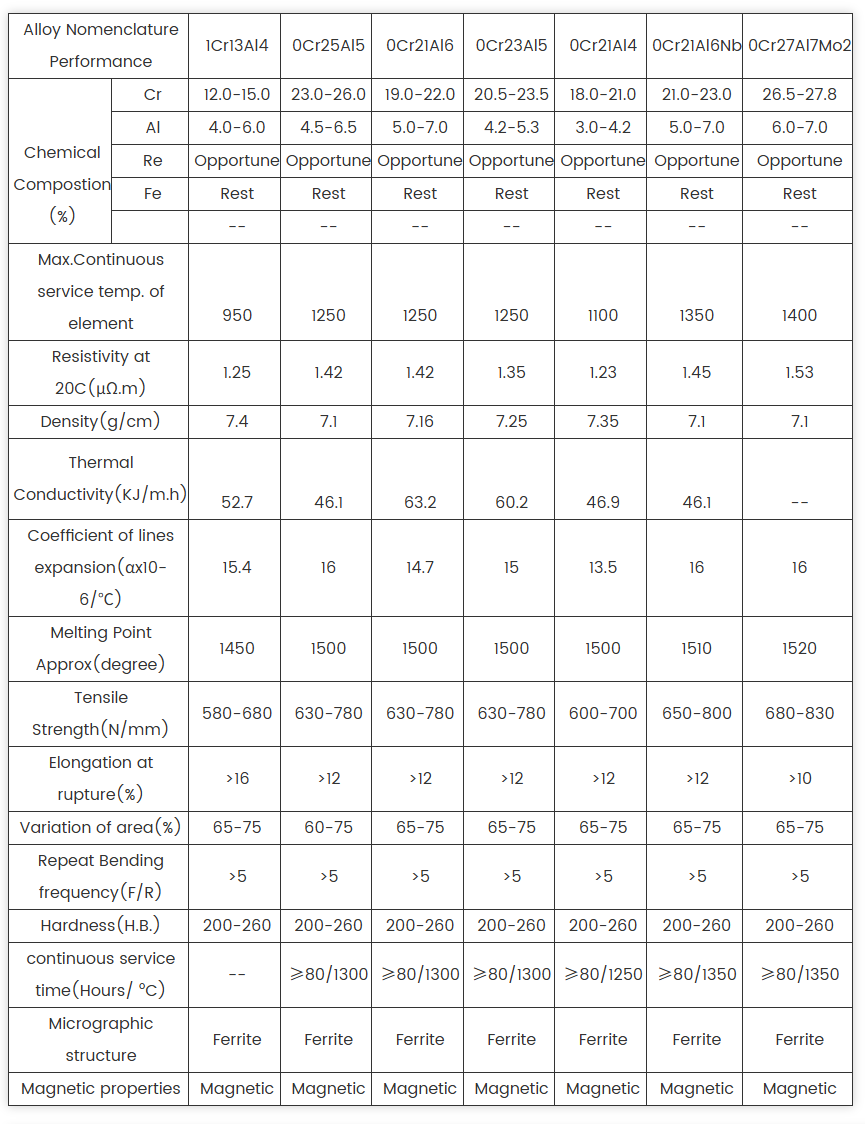

With ~25% chromium and 5% aluminum, 0Cr25Al5 is designed to handle temperatures up to 1350°C, making it ideal for kilns, heat-treating furnaces, or high-temp resistors. Its oxidation resistance is next-level, forming a protective Al2O3 oxide layer above 1000°C that shields it from degradation in sulfur-rich or acidic atmospheres—perfect for harsh industrial settings. The corrosion resistance is just as impressive, standing up to chemical or metallurgical environments where other materials might buckle.

The electrical resistivity, around 1.40 µΩ·m, makes this wire super efficient at generating heat, ensuring consistent performance for heating elements or industrial resistors. Its tensile strength (~670 MPa) keeps it durable, though it’s a bit less flexible than lower-grade FeCrAl alloys, so we optimize designs for strength. With a thermal conductivity of ~11 W/mK, it distributes heat steadily, and we can supply it in coils, strips, or custom forms to fit any high-temperature application, from ceramic firing to aerospace components.

The industry in 2025 is all about durability and sustainability, and our 0Cr25Al5 wire is right on trend. There’s a massive demand for high-temperature, corrosion-resistant materials in aerospace, automotive, and energy sectors, like EV battery systems, turbine parts, or industrial ovens. Being 100% recyclable, it’s a great fit for eco-friendly manufacturing. As high-efficiency heating and automation keep trending, this wire’s heat resistance and reliability make it a top pick for cutting-edge applications.

Sure, Nichrome Cr20Ni80 is awesome for lower-temperature setups and a bit more formable, but our 0Cr25Al5 wire’s higher heat tolerance and oxidation resistance make it the champ for extreme environments. Stainless Steel 316 is corrosion-resistant but can’t match FeCrAl’s high-temperature performance or resistivity. Just watch out for creep at max temps, though this wire handles most industrial conditions like a pro.

From industrial kilns to high-temp heating elements, our 0Cr25Al5 FeCrAl wire delivers the heat resistance, durability, and efficiency that keep industries blazing forward with confidence.

Product Description:

The FeCrAl wire comes in three surface finishes: bright, oxidized, or annealed. The bright surface finish is ideal for applications where aesthetics are important, while the oxidized finish is better suited for applications where corrosion resistance is required. The annealed finish is perfect for applications where the wire needs to be bent or shaped.

The FeCrAl wire is a versatile product that is used in a variety of applications. It is commonly used in heating elements, industrial furnaces, and household appliances. The wire is also used in the automotive industry for sensors and ignition systems.

The FeCrAl wire is available in different forms, including bright steel FeCrAl wire and copper clad steel wire. The bright steel FeCrAl wire is a popular choice because of its high-temperature resistance and durability. The copper clad steel wire is used in applications where conductivity is important.

The FeCrAl wire has a maximum working temperature of 1250℃, making it an excellent choice for high-temperature applications. It can withstand extreme temperatures without losing its structural integrity, making it a reliable and long-lasting product.

In conclusion, the FeCrAl wire is an excellent choice for applications that require high-temperature resistance. The wire is available in different forms, including bright steel FeCrAl wire and copper clad steel wire. It has a maximum working temperature of 1250℃ and is a reliable and long-lasting product.

Applications:

One of the most common applications for DLX FeCrAl Wire is in the heating industry. The wire is often used to make heating elements for ovens, furnaces, and other high-temperature industrial applications. The wire's ability to withstand high temperatures and its magnetic properties make it an ideal choice for these types of applications.

Another common application for DLX FeCrAl Wire is in the automotive industry. The wire is used in the production of catalytic converters, where it is used to help convert harmful emissions into less harmful gases. The wire's high-temperature resistance and magnetic properties make it an excellent choice for this application.

In the electronics industry, DLX FeCrAl Wire is often used to make resistors and other components that require high-temperature resistance. The wire's bright, oxidized surface makes it easy to work with and provides excellent conductivity. In addition, the wire can be annealed to improve its flexibility and make it easier to work with in a variety of applications.

Other common applications for DLX FeCrAl Wire include the production of heating coils for appliances, the production of heating elements for industrial machinery, and the manufacture of thermocouples. With its bright, oxided, or annealed surface, the wire is easy to work with and can be used in a variety of applications.

Overall, DLX FeCrAl Wire is a highly versatile product that can be used in a wide variety of applications and scenarios. Whether you are working in the heating industry, the automotive industry, or the electronics industry, this bright steel FeCrAl wire is an excellent choice for your needs.

Customization:

We offer customization options for the surface of the FeCrAl wire, including bright, oxided, and acid finishes. Additionally, we offer options for the condition of the wire, including hard and soft.

Our FeCrAl wire is made of high-quality iron-chromium-aluminum material, ensuring durability and reliability. We offer both bright steel FeCrAl wire and annealed FeCrAl wire to suit your specific application.

Support and Services:

Our FeCrAl wire product technical support team is available to assist with any questions related to product selection, installation, and maintenance. We offer a range of services including product testing, analysis, and custom design to meet your specific requirements. Our team can provide technical documentation, such as data sheets, material safety data sheets, and application notes, to ensure the proper use and handling of the product. Additionally, we offer training and on-site support to help you optimize the performance of our products. Contact us today for more information.

Packing and Shipping:

Product Packaging:

The FeCrAl Wire will be packaged in a sturdy cardboard box

Each box will contain 10 spools of wire, each spool weighing 1kg

The spools will be individually wrapped in plastic to prevent any damage during transit

A label with the product name, quantity, and specifications will be affixed to each box

Shipping:

The FeCrAl Wire will be shipped via a reputable courier service

Shipping costs will be calculated based on the destination and weight of the order

Once the order has been shipped, the customer will receive a tracking number to track their package

The estimated delivery time will depend on the destination, but we will provide an estimated delivery date at the time of purchase

About Us:

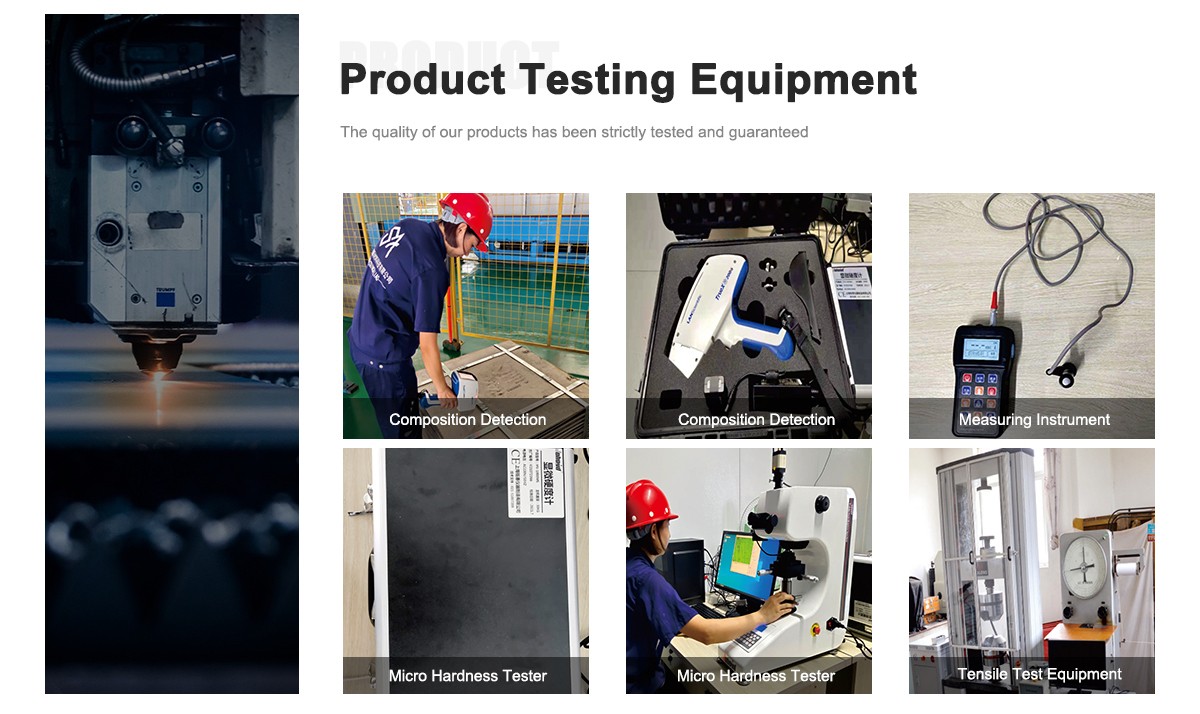

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

Why use 0Cr25Al5 FeCrAl wire for high-temperature heating?

Its heat stability and oxidation resistance make it ideal for reliable performance in extreme conditions.

How does 0Cr25Al5 compare to other FeCrAl grades like 0Cr21Al4?

0Cr25Al5 has higher chromium and aluminum for better heat and oxidation resistance, but less formability.

Can this wire handle industrial furnace temperatures?

Yup, it’s stable up to 1350°C, perfect for furnaces and kilns.

Is 0Cr25Al5 wire corrosion-resistant?

Totally, it resists corrosion in harsh chemical or sulfur-rich environments.

What’s the benefit of its high electrical resistivity?

It ensures efficient heat generation, great for consistent heating elements.

Is this FeCrAl wire recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

Can it be used in precision heating elements?

Absolutely, its high resistivity and stability are ideal for accurate heating systems.

Is 0Cr25Al5 wire cost-effective for industrial use?

Yes, its durability and performance make it a budget-friendly choice over time.

-

What is FeCrAl Fiber Felt?

Enquire Now -

0Cr27Al7Mo Heating Resistance Wire (2.0mm Diameter) – Specifications

Enquire Now -

0Cr21Al6 FeCrAl Wire Corrosion Resistance Heating Electric Resistance Alloy Wires for Household App

Enquire Now -

Heating Element Wire Resistance Wire FeCrAl Alloy Wire With Superior Quality

Enquire Now