Manufacture Heating Resistance FeCrAl Ferroalloy 0Cr21Al4 0Cr21Al6Nb Wire For Industrial Use

- Product Details

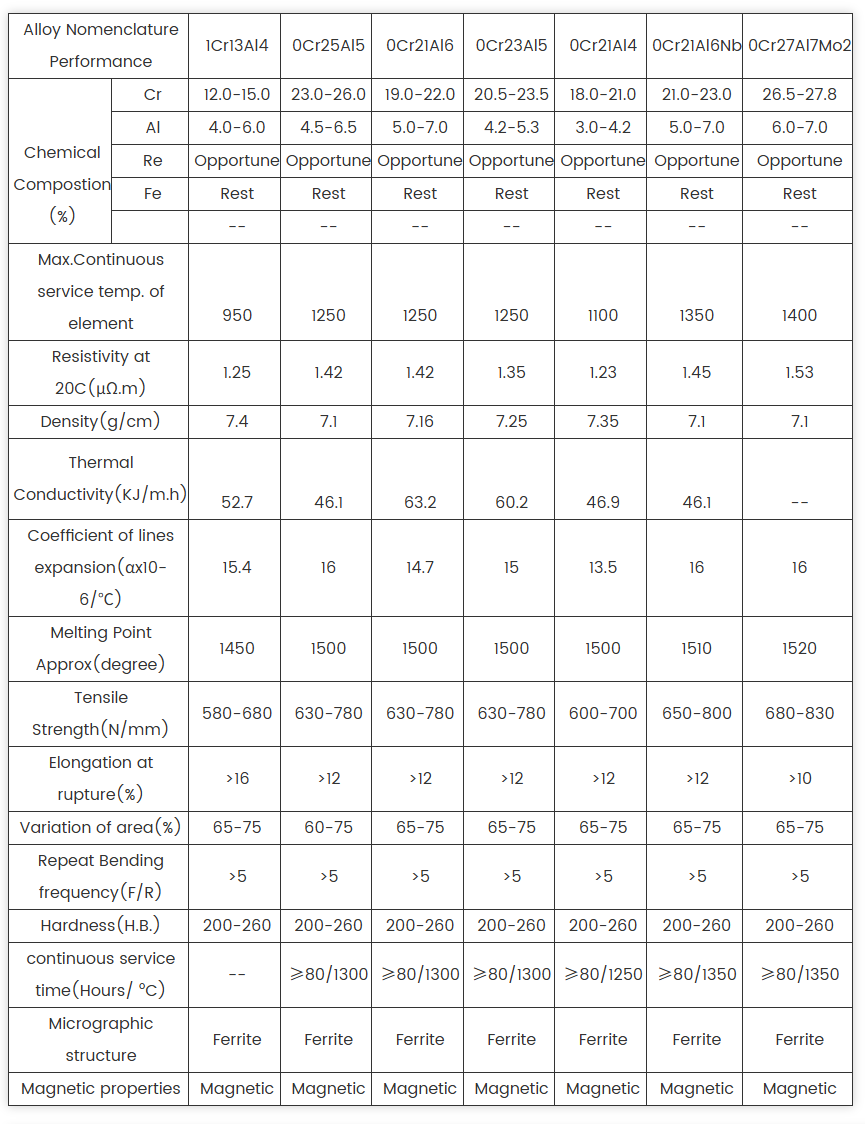

The production of 0Cr21Al4 and 0Cr21Al6Nb FeCrAl ferroalloy wires involves advanced metallurgical processes to ensure high quality for industrial heating applications. Manufacturers like Hangzhou Ualloy Material Co., Ltd. and Changzhou DLX Alloy Co., Ltd. follow rigorous steps, as outlined below:

Raw Material Selection: High-purity iron, chromium, aluminum, and (for 0Cr21Al6Nb) niobium are sourced to meet precise compositional standards (~21% Cr, 4% Al for 0Cr21Al4; ~21% Cr, 6% Al, 0.5% Nb for 0Cr21Al6Nb).

Melting and Alloying: Materials are melted in electric arc or vacuum induction furnaces to form a homogeneous ferroalloy. The addition of niobium in 0Cr21Al6Nb enhances high-temperature stability.

Casting and Hot Rolling: The molten alloy is cast into billets, then hot-rolled into rods or strips, reducing size while maintaining structural integrity.

Cold Drawing: Rods are drawn through dies to achieve desired wire diameters (e.g., 0.6mm for 0Cr21Al4, various sizes for 0Cr21Al6Nb). This improves precision and surface finish.

Annealing: Wires undergo bright or soft annealing to relieve stresses, enhance formability, and improve oxidation resistance. 0Cr21Al6Nb may receive additional heat treatment to optimize niobium’s creep resistance.

Surface Treatment: Wires can be supplied with bright annealed or oxidized surfaces. Oxidized surfaces enhance the Al2O3 protective layer for high-temperature use.

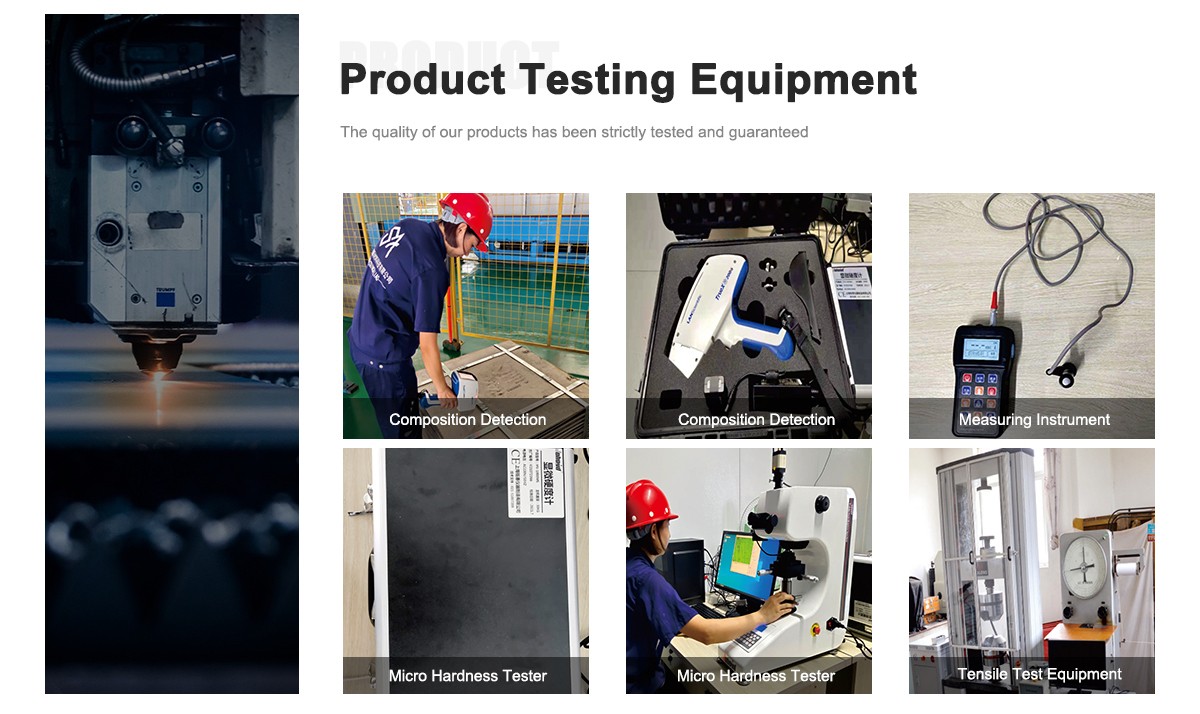

Quality Control: Manufacturers like Shanghai Tankii Alloy Material Co., Ltd. conduct chemical analysis, physical testing, and resistivity checks to ensure compliance with ISO9001 standards.

Packaging: Wires are spooled into coils, rolls, or cut lengths, packaged in spools, cartons, or wooden cases with plastic film for protection during shipping.

Industrial Applications

0Cr21Al4: Widely used in industrial furnaces, household appliances (e.g., electric stoves, heaters), and metallurgy due to its cost-effectiveness and formability. Its moderate temperature range (up to 1250°C) suits less extreme environments.

0Cr21Al6Nb: Preferred for high-temperature industrial furnaces in heat treatment, ceramics, glass, and electronics, thanks to its 1350°C capability and creep resistance. It’s also used in far-infrared devices and automotive applications.

Industry Trends in 2025

The demand for FeCrAl alloys like 0Cr21Al4 and 0Cr21Al6Nb is growing in industries prioritizing energy efficiency and sustainability. Applications in EV battery production, aerospace heat treatment, and automated furnace systems are driving adoption. Their recyclability supports eco-friendly manufacturing, and manufacturers like Nantong Juntai Alloy Fiber Co., Ltd. offer customized solutions to meet specific industrial needs.

Comparison with Nichrome

Nichrome Cr20Ni80 is formable and corrosion-resistant but limited to 1200°C, making 0Cr21Al4 and 0Cr21Al6Nb better for higher-temperature industrial uses. 0Cr21Al6Nb’s niobium addition gives it an edge in creep resistance over both 0Cr21Al4 and Nichrome.

Considerations

Creep at Max Temps: Monitor 0Cr21Al4 above 1250°C and 0Cr21Al6Nb above 1350°C to prevent deformation.

Customization: Manufacturers can produce stranded, twisted, or spiral wires to meet specific furnace designs.

For industrial heating, our 0Cr21Al4 and 0Cr21Al6Nb FeCrAl wires, manufactured with precision by industry leaders, offer unmatched heat resistance, durability, and efficiency. Contact suppliers like Hangzhou Ualloy or Shanghai Tankii for quotes, samples, or custom orders to power your industrial furnaces effectively.

Product Description:

The specific heat capacity of this wire is 0.49 J/g·K, which means it can absorb and release heat efficiently. It also has a melting point of 1500°C, making it ideal for use in high-temperature environments.

The surface of our Alloy FeCrAl Wire comes in three different finishes: bright, oxided, and acide. The bright surface is smooth and shiny, while the oxided finish has a rusted appearance. The acide surface, on the other hand, has a matte finish.

Our wire also has excellent magnetic properties, making it suitable for use in various electromagnetic applications. It can also be used in electrical heating elements, where the magnetic properties are essential.

The maximum operating temperature of our Alloy FeCrAl Wire is 1400°C, making it ideal for use in high-temperature applications. This wire is also highly resistant to oxidation and corrosion, ensuring its longevity and durability.

Our Bare Copper FeCrAl Wire is perfect for use in various electrical applications. It is highly durable and can withstand high temperatures, making it ideal for use in heating elements, resistors, and other similar applications.

Our Black Annealed Tie Wire is a versatile and highly durable wire that is ideal for use in various applications. It is made from high-quality materials and has a black annealed finish, making it highly resistant to rust and corrosion. This wire is perfect for use in construction, fencing, and other similar applications.

For more details, pls directly contact us.

Applications:

The DLX FeCrAl Wire product can be used for a variety of applications. One common use is for heating elements in appliances such as ovens, toasters, and hair dryers. The wire is also commonly used in the production of industrial furnaces, kilns, and other high-temperature equipment.

The DLX FeCrAl Wire product is also perfect for the production of Black Annealed Tie Wire. The wire is perfect for tying together building materials such as rebar and mesh. The Black Annealed Tie Wire is a popular choice for construction workers and contractors as it is strong, durable, and easy to use.

The DLX FeCrAl Wire product is also commonly used in the production of various types of resistors and electrical heating equipment. The wire is an essential component in the production of electronic cigarettes, which are becoming increasingly popular around the world.

In conclusion, the DLX FeCrAl Wire product is a versatile and reliable wire that can be used for a variety of applications. It is perfect for heating elements, industrial equipment, black annealed tie wire, resistors, and electronic cigarettes. With its high-temperature resistance, magnetic properties, and durability, the DLX FeCrAl Wire product is the perfect choice for any project that requires a strong and reliable wire.

Support and Services:

Our FeCrAl wire products are designed and manufactured to meet the highest quality standards. If you require technical support or services for your FeCrAl wire product, we are here to help. Our team of experts can assist you with any questions or issues you may have, including material properties, product selection, and application recommendations. We also offer custom design and manufacturing services to meet your specific needs. Contact us for more information on how we can support your FeCrAl wire product.

Packing and Shipping:

Product Packaging:

The FeCrAl wire is packed in spools of various sizes depending on the customer's requirement.

The spools are then placed in a cardboard box to ensure safe transport.

The box is labeled with the product name, size, and quantity.

Shipping:

The FeCrAl wire is shipped via ground or air transportation, depending on customer preference and urgency.

The product is carefully loaded onto a pallet and secured with plastic wrap to prevent damage during transit.

The pallet is labeled with the customer's address, contact information, and any special instructions.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

Why use 0Cr21Al4 and 0Cr21Al6Nb FeCrAl wires for industrial heating?

0Cr21Al4 is cost-effective and formable for moderate-temperature applications, while 0Cr21Al6Nb’s niobium addition enhances creep resistance and higher temperature tolerance, ideal for demanding industrial furnaces.

What industrial applications are these wires suited for?

They’re used in industrial furnaces, heat-treating systems, ceramic kilns, and electrical heating elements for metallurgy, electronics, and automotive industries.

How do their temperature capabilities differ?

0Cr21Al4 operates up to 1250°C, while 0Cr21Al6Nb can handle up to 1350°C due to its niobium-enhanced composition.

Are these wires corrosion-resistant?

Both resist corrosion in sulfur-rich or acidic environments, with 0Cr21Al6Nb offering slightly better performance due to its higher aluminum content and niobium.

What’s the benefit of high electrical resistivity?

High resistivity ensures efficient heat generation, optimizing energy use in industrial heating systems.

Are these FeCrAl wires recyclable?

100% recyclable, aligning with eco-friendly manufacturing trends.

How does niobium improve 0Cr21Al6Nb?

Niobium increases creep resistance and structural stability at high temperatures, extending service life in harsh conditions.

Are these wires cost-effective for industrial use?

0Cr21Al4 is highly cost-effective for moderate applications, while 0Cr21Al6Nb, though slightly pricier, offers superior durability for high-temperature environments.

-

What is FeCrAl Fiber Felt?

Enquire Now -

0Cr27Al7Mo Heating Resistance Wire (2.0mm Diameter) – Specifications

Enquire Now -

0Cr21Al6 FeCrAl Wire Corrosion Resistance Heating Electric Resistance Alloy Wires for Household App

Enquire Now -

Heating Element Wire Resistance Wire FeCrAl Alloy Wire With Superior Quality

Enquire Now