Corrosion And Oxidation Resistant iron chromium Wire For Heat Treatment

- Product Details

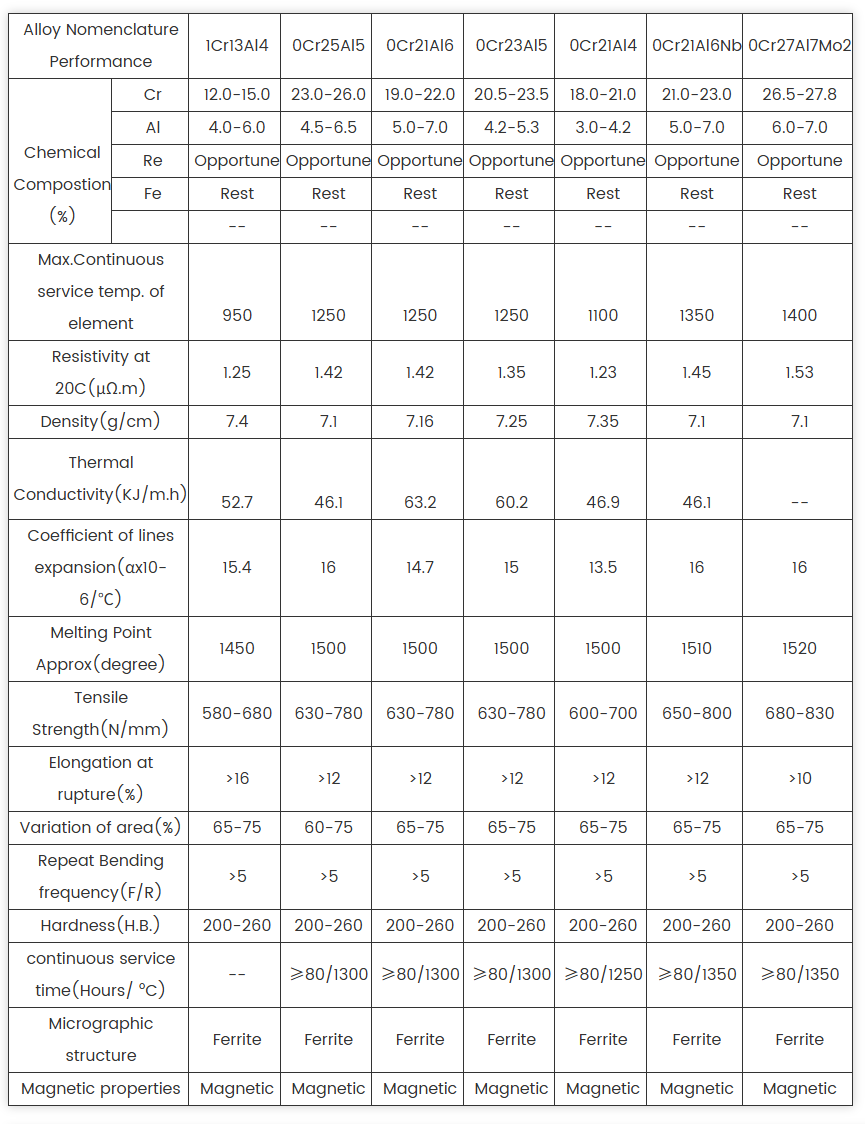

Product Description:

One of the key advantages of the FeCrAl Alloy is its versatility in heat treatments. It can be treated to achieve a bright, oxided, or acid surface, depending on the specific application requirements. This makes it a popular choice for heating elements and other high-temperature applications where surface properties are critical.

In addition, the FeCrAl Alloy boasts excellent tensile strength, ranging from 630-780MPA, making it a strong and reliable choice for demanding applications. Its exceptional weldability and formability also make it a popular material for fabricating custom shapes and designs for specific applications.

Finally, the FeCrAl Alloy is known for its outstanding corrosion resistance, especially in high-temperature environments. This makes it an ideal choice for applications where corrosive gases or liquids may be present.

In summary, the FeCrAl Alloy, also known as Resistohm 145, is an excellent choice for industrial heating applications due to its exceptional thermal and electrical properties, versatility in heat treatments, excellent tensile strength, weldability and formability, and outstanding corrosion resistance.

Applications:

One of the most common product applications for the FeCrAl Alloy is in the heating industry. Due to its excellent oxidation resistance, the iron chromium alloy is often used in the manufacturing of heating elements for ovens, toasters, and other high-temperature appliances. The DLX FeCrAl Alloy product is also a popular choice for use in the production of industrial furnaces due to its ability to withstand high temperatures and resist corrosion.

Another popular application for the FeCrAl Alloy is in the automotive industry. The iron chromium alloy is often used in the manufacturing of exhaust systems due to its ability to resist high temperatures and corrosion. The DLX FeCrAl Alloy product is also a popular choice for use in the production of catalytic converters due to its high-temperature resistance and excellent oxidation resistance.

The FeCrAl Alloy is also commonly used in the production of household appliances such as hair dryers and electric irons. The iron chromium alloy is often used in the heating elements of these products due to its high-temperature resistance and excellent weldability. Additionally, the DLX FeCrAl Alloy product is a popular choice for use in the production of resistors due to its excellent electrical conductivity and resistance to corrosion. The FeCrAl Alloy is also commonly used in the production of heating wire for electronic cigarettes, with the DLX FeCrAl Alloy product being a popular choice for use in this industry.

In conclusion, the DLX FeCrAl Alloy product is a versatile and durable material that is commonly used in a wide range of product applications. Its excellent weldability, high-density range, and excellent oxidation resistance make it a popular choice for use in the heating, automotive, household appliance, and electronics industries. Whether you are manufacturing heating elements, exhaust systems, or resistors, the FeCrAl Alloy is a reliable and long-lasting choice.

Support and Services:

Our FeCrAl Alloy product comes with technical support and services to ensure optimal performance and longevity.

Our team of experts can provide:

Material selection guidance

Design recommendations

Installation advice

Maintenance and repair assistance

Troubleshooting help

We are committed to providing excellent customer service and technical support to ensure your satisfaction with our FeCrAl Alloy product.

Packing and Shipping:

Product Packaging:

The FeCrAl Alloy product will be packed in a sturdy cardboard box.

The box will be securely sealed with packing tape.

The product will be wrapped in bubble wrap to provide extra protection during shipping.

A label with the product name, quantity, and handling instructions will be attached to the box.

Shipping:

The FeCrAl Alloy product will be shipped via a reliable carrier service.

The shipping cost will be calculated based on the weight and destination of the package.

The estimated delivery time will be provided to the customer at the time of purchase.

The customer will receive a tracking number to track their package during transit.

About Us:

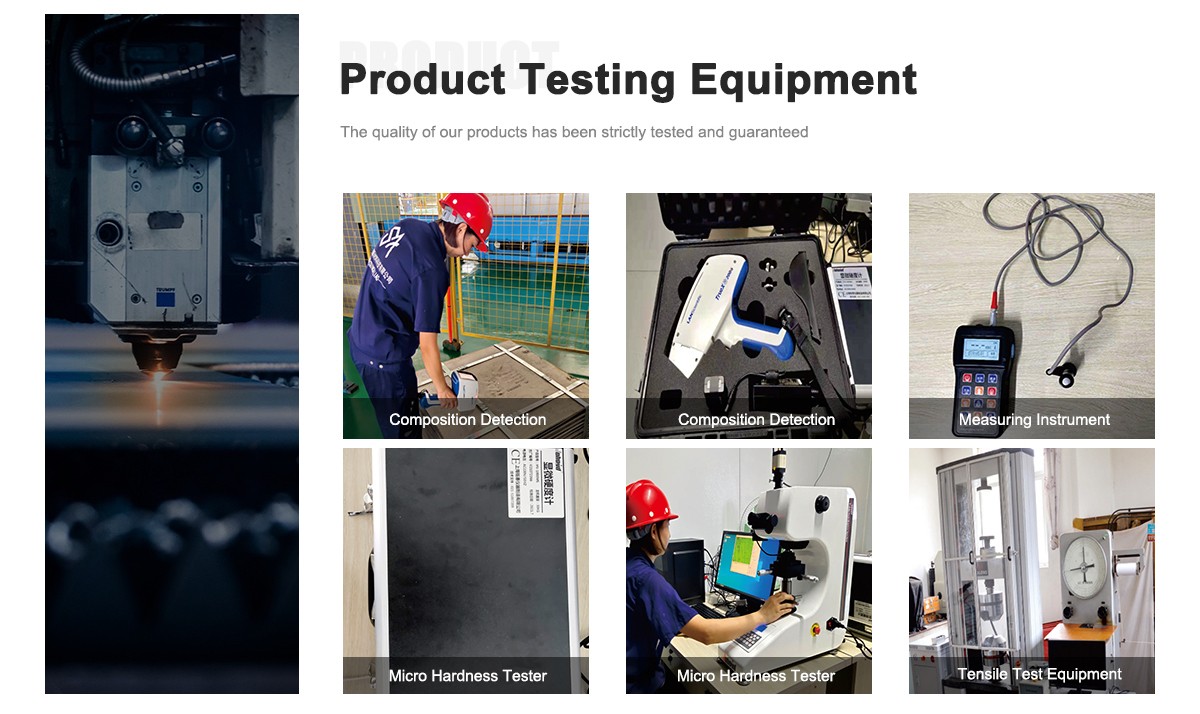

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

Q: What is the brand name of this product?

A: The brand name of this product is DLX.

Q: What is the model number of this product?

A: The model number of this product is FeCrAl Alloy.

Q: Where is this product manufactured?

A: This product is manufactured in China JiangSu.

Q: What are the applications of this product?

A: This product is commonly used in heating elements, furnaces, and electrical appliances.

Q: What are the available sizes and shapes of this product?

A: This product is available in various sizes and shapes, including wires, strips, and sheets.

-

What is FeCrAl Fiber Felt?

Enquire Now -

0Cr27Al7Mo Heating Resistance Wire (2.0mm Diameter) – Specifications

Enquire Now -

0Cr21Al6 FeCrAl Wire Corrosion Resistance Heating Electric Resistance Alloy Wires for Household App

Enquire Now -

Heating Element Wire Resistance Wire FeCrAl Alloy Wire With Superior Quality

Enquire Now